Polyglycolic-acid-orientation nanometer fiber bundle and preparing method thereof

A technology of polyglycolic acid and nanofibers, applied in fiber processing, conjugated synthetic polymer artificial filaments, heat treatment of artificial filaments, etc., can solve the unstable structure of nanofibers, low production efficiency of electrospinning, and inability to form nanofibers Fiber and other problems, to achieve the effect of improving degradation resistance, regular structure, and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

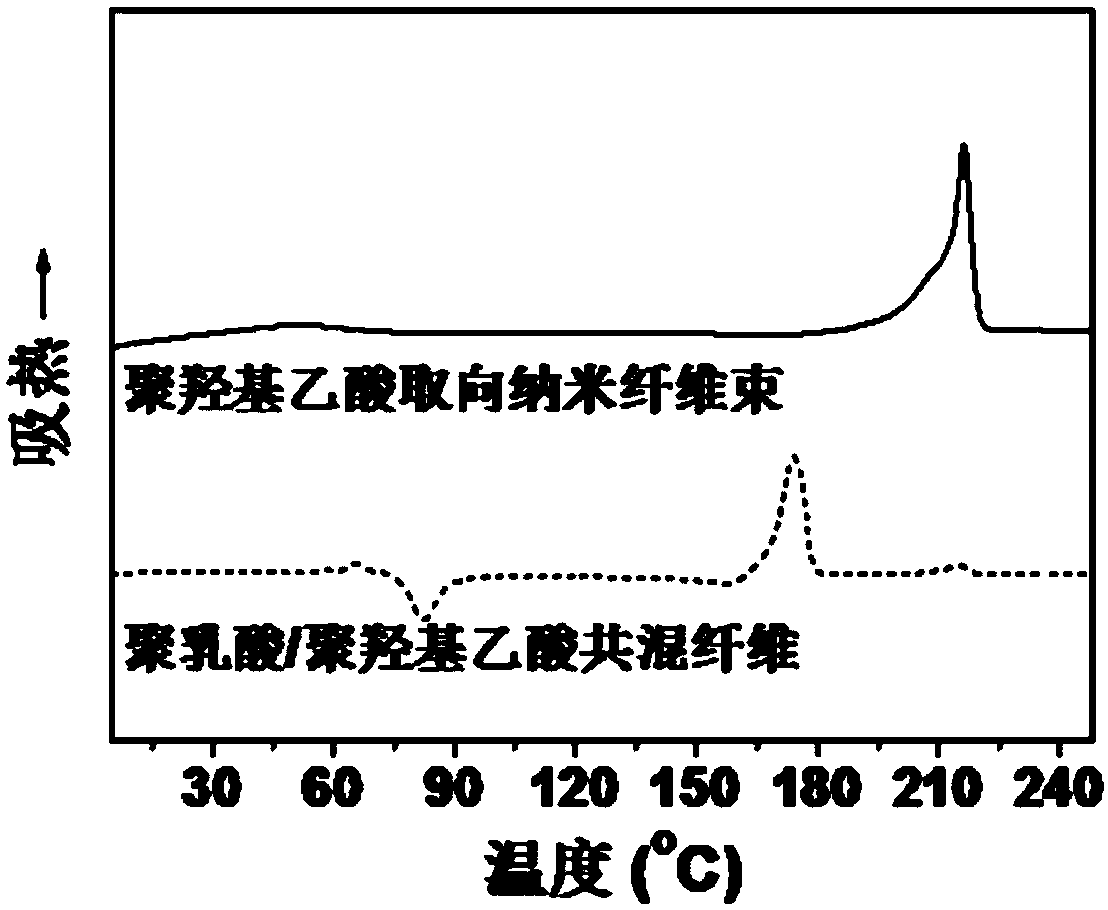

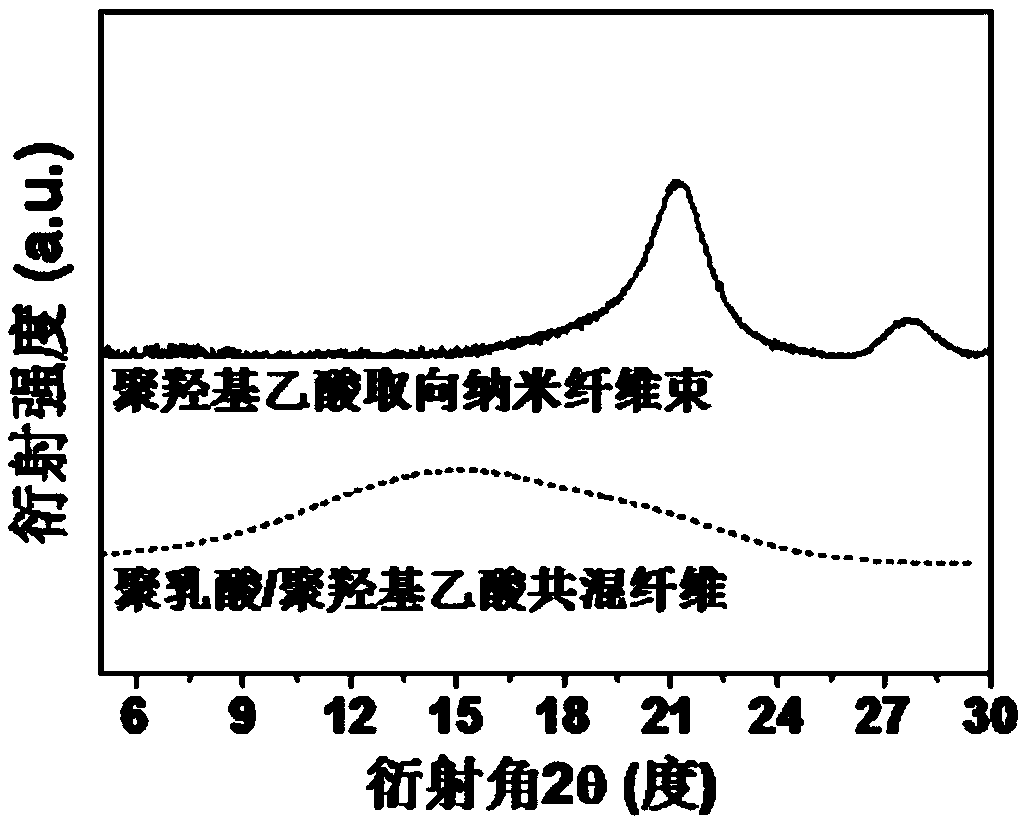

[0037] Polylactic acid with a weight average molecular weight of 60,000 and a molar content of L optical isomer of 88% and polyglycolic acid with a weight average molecular weight of 150,000 were vacuum-dried at a drying temperature of 90±5°C and a drying time of 16 hours. The water content is 40ppm; 91 kg of dried polylactic acid and 9 kg of dried polyglycolic acid are physically mixed in a high-speed mixer; the mixture is injected into a single-screw extruder to melt, and extruded through a metering pump and a spinneret hole. When the spinning temperature is 242°C and the spinning speed is 2500m / min, the polylactic acid / polyglycolic acid blended fibers with an average diameter of 50 microns are collected to prepare rough worsted yarns; multiple rough worsted yarns Gathered into bundles at a speed of 7.2m / min and passed through a 6-meter-long, 180°C constant temperature hot box for heat treatment. In the water tank, it is rapidly cooled to room temperature within 10 seconds, ...

Embodiment 2

[0039] Take polylactic acid with a weight-average molecular weight of 60,000 and a molar content of L optical isomer of 96%, and polyglycolic acid with a weight-average molecular weight of 600,000 for vacuum drying at a drying temperature of 90±5°C and a drying time of 16 hours. The water content is 42ppm; 97 kg of dried polylactic acid and 3 kg of dried polyglycolic acid are physically mixed in a high-speed mixer; the mixture is injected into a single-screw extruder to melt, and extruded through a metering pump and a spinneret hole. When the spinning temperature is 235°C and the spinning speed is 500m / min, the polylactic acid / polyglycolic acid blended fibers with an average diameter of 80 microns are collected to prepare rough worsted yarns; multiple rough worsted yarns Gathered into bundles at a speed of 12m / min and pass through a 6-meter-long, 160°C constant temperature hot box for heat treatment, the heat treatment time is 30 seconds, and then introduced into a 3-meter-long...

Embodiment 3

[0041] Polylactic acid with a weight average molecular weight of 60,000 and a molar content of L optical isomer of 96% and polyglycolic acid with a weight average molecular weight of 100,000 were vacuum-dried at a drying temperature of 90±5°C and a drying time of 16 hours. The water content is 45ppm; 95 kg of dried polylactic acid and 5 kg of dried polyglycolic acid are physically mixed in a high-speed mixer; the mixture is injected into a single-screw extruder to melt, and extruded through a metering pump and a spinneret hole. When the spinning temperature is 239°C and the spinning speed is 4500m / min, the polylactic acid / polyglycolic acid blended fibers with an average diameter of 10 microns are collected, and the coarse worsted yarn is prepared; multiple rough worsted yarns Gathered into bundles at a speed of 18m / min, pass through a 6-meter-long, 190°C constant temperature hot box for heat treatment, so that the heat treatment time is 20 seconds, and then guide it into a 3-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com