Chromium doped barium stannate nano-powder with adjustable energy gap and preparation method thereof

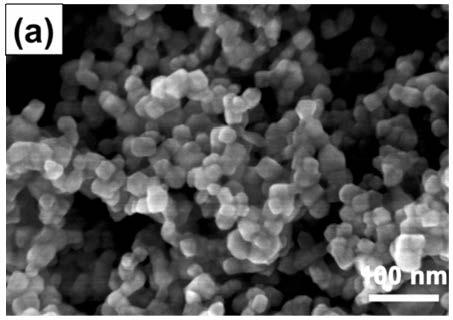

A nano-powder, chromium-doped technology, applied in the direction of nanotechnology, chemical instruments and methods, tin compounds, etc., can solve problems such as difficult to achieve energy level matching of the hole transport layer, and achieve broad absorption range and uniform particle size distribution Small, high-quality crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

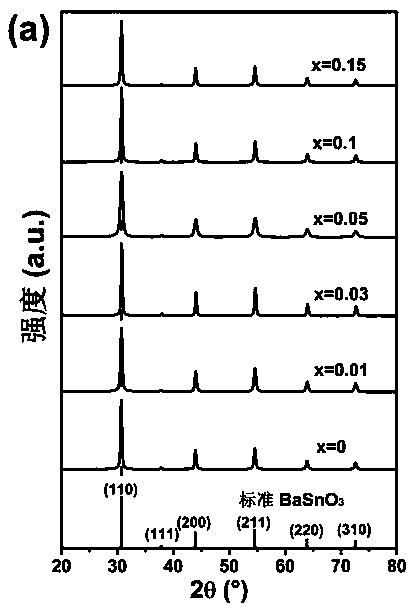

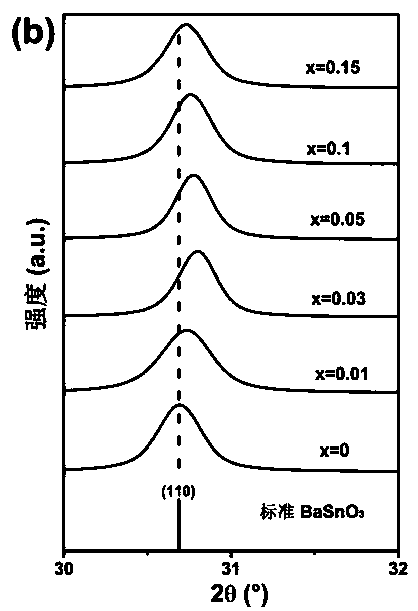

[0045] The invention relates to a chromium-doped barium stannate nano-powder with adjustable bandgap width and a preparation method thereof. The composition chemical formula of the chromium-doped barium stannate nano-powder is BaSn 1-x Cr x o 3 , where 03 The Sn bit in . The preparation method may include: using water-soluble tin salt, water-soluble barium salt, and water-soluble chromium salt as raw materials, using peroxide aqueous solution as solvent, and adopting a peroxide precipitation method to prepare a precursor powder. After heat treatment at a certain temperature, a chromium-doped barium stannate nanopowder with uniform particle size distribution, good crystallinity and controllable optical bandgap width can be obtained, which can be used as a perovskite light-absorbing material. Through element doping, the electronic structure can be changed, and the optical bandgap of the stannate material can be adjusted, so that it can be transformed from an intrinsic wide ban...

Embodiment 1

[0061] (1) Precursor powder preparation. Weigh 10mmol of tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), barium chloride dihydrate (BaCl 2 2H 2 O), dissolved in 170ml 30% hydrogen peroxide (H 2 o 2 ) aqueous solution, then add chelating agent 5mmol monohydrate citric acid (C 6 h 8 o 7 ·H 2 0), after stirring for 15 minutes, a clear solution was obtained, and then the precipitating agent ammonia (NH 3 ·H 2 O) until the pH value of the solution is 10, and finally react for 60 minutes under magnetic stirring in a water bath at 50° C. to obtain a precursor powder;

[0062] (2) Precursor powder is centrifuged. The precursor powder was ultrasonically cleaned in deionized water and absolute ethanol in sequence, and centrifuged several times until the supernatant had a pH value of 7, centrifuged for 10 minutes each time, and finally dried at 70°C;

[0063] (3) heat treatment. The obtained dried precursor powder is heat-treated in a muffle furnace at 800°C for 2 hours, an...

Embodiment 2

[0066] Preparation of BaSn 0.95 Cr 0.05 o 3 Nano powder

[0067] Weigh 9.5mmol tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), 10mmol dihydrate barium chloride (BaCl 2 2H 2 O) and 0.5mmol chromium trichloride hexahydrate (CrCl 3 ·6H 2 O) successively dissolved in 170ml 30% hydrogen peroxide (H 2 o 2 ) in aqueous solution. All the other steps are the same as in Example 1.

[0068] The structure, morphology and performance of the above-mentioned nano-powder with adjustable band gap were tested and analyzed.

[0069] As can be seen from Figure 2 (a), the BaSn prepared in Example 2 0.95 Cr 0.05 o 3 Crystal Structure of Nanopowders and Cubic Phase BaSnO 3 same. Its field emission scanning electron microscope photo is as Fig. 3 (d), and its particle size distribution picture is as Fig. 4 (d), the BaSn of embodiment 2 0.95 Cr 0.05 o 3 The particle size of the nanopowder is 30nm. As can be seen from Figure 5(b), the prepared BaSn 0.95 Cr 0.05 o 3 Nano-powder ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com