Preparation process of single/multi-element doped sodium titanate nanorod array coating

A nanorod array and preparation process technology, which is applied in the field of bioactivation modification of medical metal surfaces, can solve the problems of inaccurate regulation of nanorod configuration parameters, and achieve the effects of high binding strength, simple composition and good biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

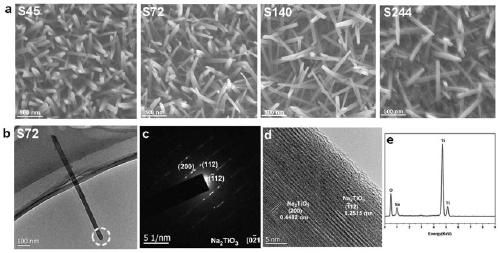

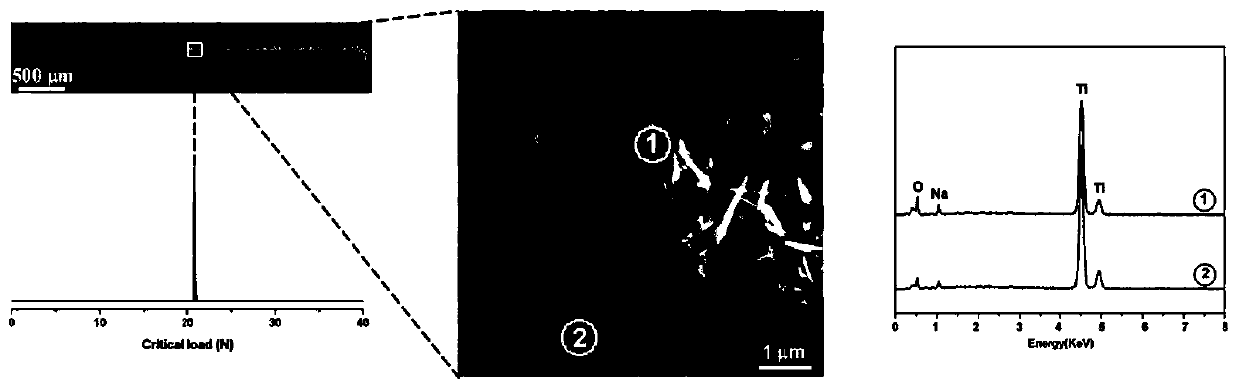

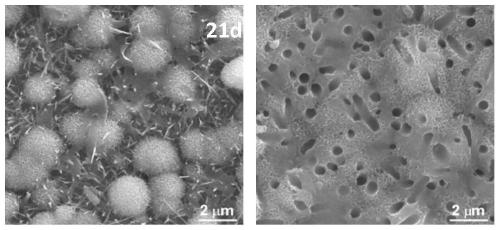

[0034] Put the pure titanium sheet sample in a high-pressure reactor, add NaOH solution with a concentration of 0.3-2M, the filling degree of the solution is 20%, conduct hydrothermal treatment at a temperature of 100°C for 0-1.5 hours, discard the liquid in the reactor, and re- Add NaOH with a concentration of 0.5M, the filling degree of the solution is 20%, and hydrothermally treat at 220°C for 3.5 to 6 hours to obtain the sodium titanate nanorod array coating. The nanorods are nearly perpendicular to the titanium substrate, and their diameter is about 67nm, the pitch is about 72nm, and the length is about 2μm. The surface and cross-section microscopic morphology SEM and nanorod TEM of the coating refer to figure 1 (a), (b) and (c), its scratch test acoustic emission signal and scratch morphology refer to figure 2 , the bonding strength between the coating and the titanium substrate is 20.8±0.1N, and the surface SEM of the sodium titanate nanorod array coating after SBF so...

Embodiment 2

[0037] Put the pure titanium sheet sample in a high-pressure reactor, and add a NaOH solution with a concentration of 1M, the solution filling degree is 20%, hydrothermally treat it at a temperature of 100°C for 1.5 hours, discard the liquid in the reactor, and add a concentration of 0.5 NaOH solution of M, the filling degree of the solution is 20%, and the hydrothermal treatment is carried out at a temperature of 220°C for 3.5 hours to obtain the sodium titanate nanorod array coating (S72). The sodium titanate nanorod array coating (S72) was placed in an autoclave, and Mg(CH 3 COO) 2 Solution, hydrothermally treated at 100°C for 24 hours to obtain a magnesium-doped sodium titanate nanorod array coating, the nanorods are nearly perpendicular to the titanium substrate, the diameter is about 67nm, the spacing is about 72nm, and the length is about 2μm. The morphology of the nanorods did not change substantially before and after doping. Its surface and cross-sectional microscop...

Embodiment 3

[0040] Put the pure titanium sheet sample in a high-pressure reactor, and add a NaOH solution with a concentration of 1M, the solution filling degree is 20%, hydrothermally treat it at a temperature of 100°C for 1.5 hours, discard the liquid in the reactor, and add a concentration of 0.5 NaOH solution of M, the filling degree of the solution is 20%, and the hydrothermal treatment is carried out at a temperature of 220°C for 3.5 hours to obtain the sodium titanate nanorod array coating (S72). The sodium titanate nanorod array coating (S72) was placed in an autoclave, and a concentration of 0.01mM Ca(CH 3 COO) 2 The solution was hydrothermally treated at a temperature of 100°C for 24 hours to obtain a calcium-doped sodium titanate nanorod array coating. The nanorods were nearly perpendicular to the titanium substrate, with a diameter of about 67nm, a spacing of about 72nm, and a length of about 2μm. The morphology of the nanorods did not change substantially before and after do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com