Catalyst for directly preparing olefin and aromatic hydrocarbon through synthetic gas and application thereof

A catalyst and synthesis gas technology, applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbon production from carbon oxides, etc., can solve the problems of Fischer-Tropsch synthesis catalyst activity reduction, aromatics isomerization, etc., to reduce product isomerization Effects of hydrogenation or hydrogenation side reactions, prolonging life, and promoting product diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

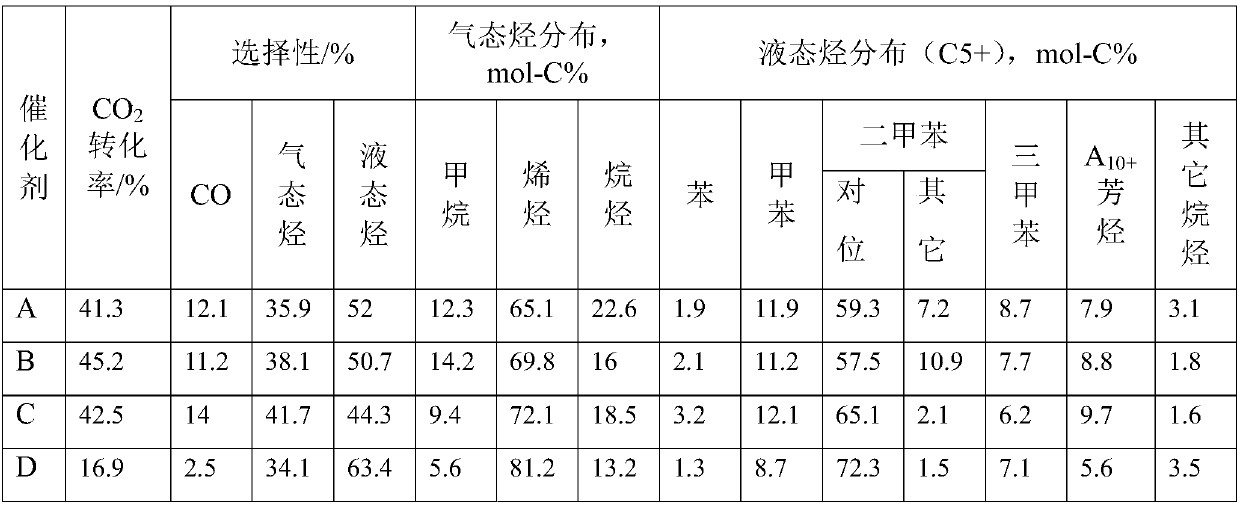

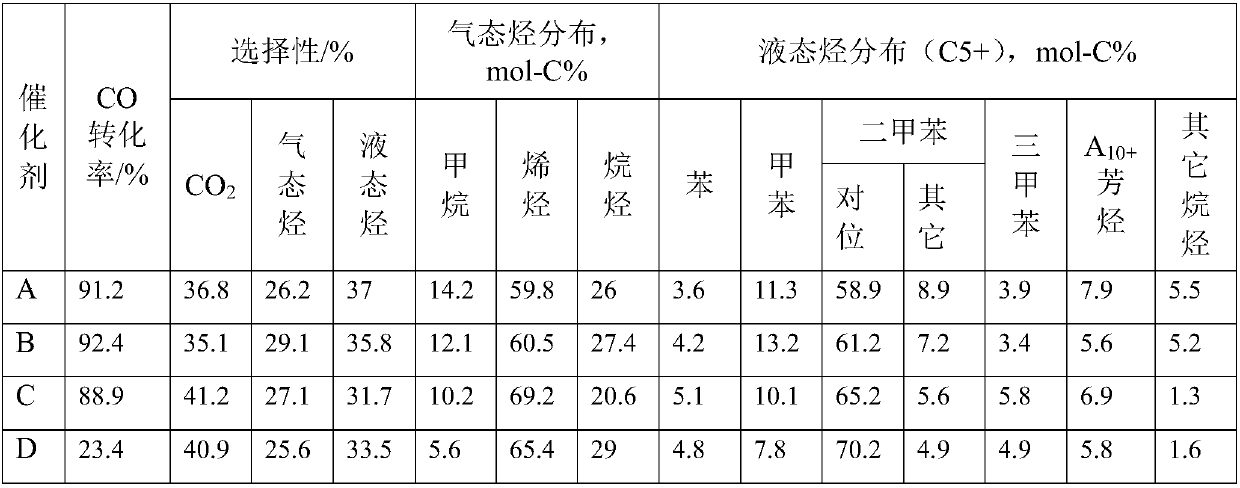

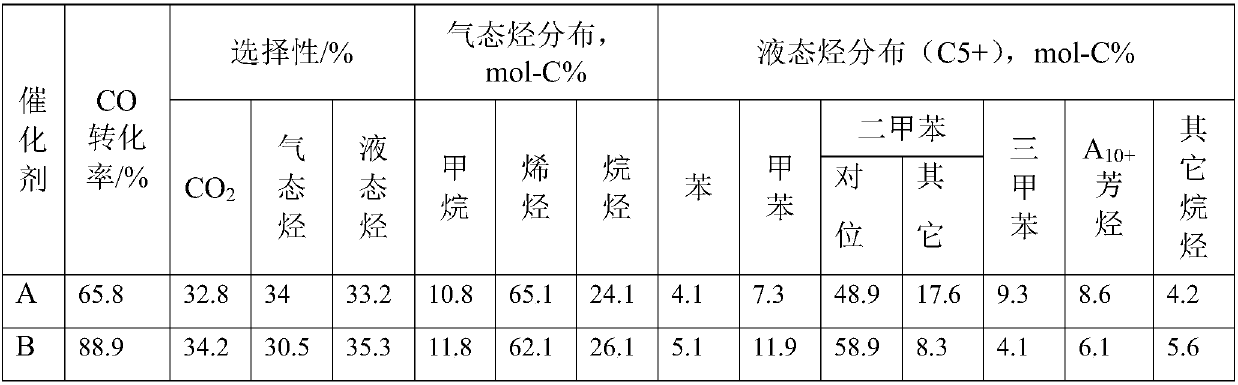

Examples

Embodiment 1

[0042] The first step is to take a certain amount of layered HZSM-5 molecular sieve (thickness is about 45nm), the silicon-aluminum ratio (Si / Al) is 15, and the oxide of zinc is deposited on the outer surface of the molecular sieve by atomic layer deposition. Specifically, put the molecular sieve into the cavity of the atomic layer deposition instrument, the cavity temperature is 100°C, and use the following mode to cycle deposit zinc oxide: diethyl zinc for 1 second, nitrogen purge for 5 seconds, water for 0.5 seconds, nitrogen purge for 5 seconds seconds, a total of 20 cycles can be obtained Zn modified HZSM-5 molecular sieve;

[0043] In the second step, the molecular sieve obtained by Zn modification is impregnated in a solution with a mass ratio of tetraethyl orthosilicate, CTAB, ethanol and water of 1:0.8:1:0.5, and is stirred continuously for 12 hours, and then placed in a hydrothermal kettle for 150 ℃ for 24 hours; cool down, take out and separate, dry at 120℃ for 12h,...

Embodiment 2

[0047] The first step is to take a certain amount of layered HZSM-5 molecular sieve (thickness about 15nm), the silicon-aluminum ratio (Si / Al) is 15, and deposit zirconium oxide on the outer surface of the molecular sieve by atomic layer deposition. Specifically, put the molecular sieve into the chamber of the atomic layer deposition instrument at a chamber temperature of 100°C, and use the following modes to cycle deposit zirconia: zirconium dichloride for 1 second, nitrogen purge for 5 seconds, water for 0.5 seconds, nitrogen gas Wash for 5 seconds and cycle 20 times to obtain Zr-modified HZSM-5 molecular sieve;

[0048] In the second step, the molecular sieve obtained by zirconium modification is immersed in a solution of ethyl orthosilicate, CTAB, ethanol and water with a mass ratio of 1:0.8:1:0.5, and is stirred continuously for 12 hours, and then placed in a hydrothermal kettle for 150 ℃ for 24 hours; cool down, take out and separate, dry at 120℃ for 12h, and roast at 50...

Embodiment 3

[0052] The first step, with the first step in embodiment 2;

[0053] In the second step, the zirconium-modified molecular sieve obtained in the first step is immersed in a solution with a mass ratio of tetraethyl orthosilicate, CTAB, ethanol and water of 2:0.8:1:0.5, and is stirred continuously for 12 hours, and then placed in water React in a hot kettle at 150°C for 24h; cool down, take out and separate, dry at 120°C for 12h, and roast at 500°C for 5h to obtain SiO 2 Molecular sieve with thicker coating;

[0054] In the third step, the molecular sieve obtained in the second step is impregnated in a mixed solution of ferric nitrate and potassium nitrate with a certain content by using the equal volume impregnation method, and then the solvent is removed by rotary evaporation, dried at 120°C for 12h, and roasted at 500°C for 5h. Catalyst sample C; after analysis, the mass fraction of HZSM-5 in catalyst C is 46.9%, the mass fraction of zirconia is 0.7%, and the SiO 2 The mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com