Stone processing sewage treatment method

A sewage treatment method and stone processing technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited adsorption capacity of sewage treatment agents and poor removal effect of heavy metal ions, etc. problem, to achieve the effect of improving the adsorption capacity and the removal rate of heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022]The preparation method of the modified ceramic particles is as follows: (1) adding the original soil of the ceramic particles into a rotary kiln, firing for 30-60 minutes at a temperature of 1500° C., and crushing them into particles with a particle size of 100-200 μm after exiting the kiln. Fine ceramic particle powder; (2) take the fine ceramic particle powder obtained in step (1) and carry out vacuum drying treatment for 12 hours, and then soak in aluminum sulfate, potassium hypochlorite and sodium lignosulfonate for 2-4 hours to make the fine ceramic particle powder After being fully soaked, filtered and dried at low temperature; (3) taking the ceramic particle fine powder after low-temperature drying obtained in step (2) and adding it to the polymerization kettle, and then adding polyvinyl alcohol, polyethylene glycol, and ammonium persulfate successively , methanol, aluminum oxide, methyl methacrylate, the reaction temperature is 78-82° C., and the reaction time is ...

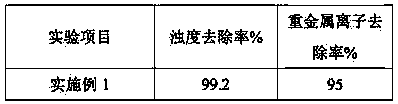

Embodiment 1

[0025] A stone processing wastewater treatment method, comprising: the sewage generated in the stone processing process first flows into a sedimentation tank, and a coagulant is added to the sewage in the sedimentation tank to accelerate the settlement of suspended solids in the stone sewage and increase the colloid and suspended solids in the sewage The suspended matter in the sewage forms stone mud at the bottom of the sedimentation tank, and the upper layer of clear water is filtered and overflows into the secondary sedimentation tank for secondary sedimentation. The bottom of the secondary sedimentation tank continues to form stone mud, and the upper layer is clear water. The upper clear water in the secondary sedimentation tank overflows to the clear water tank after being filtered, and the clear water in the clear water tank is reused. The stone mud at the bottom of the sedimentation tank and the secondary sedimentation tank is extracted through the pipeline and then treat...

Embodiment 2

[0029] A stone processing wastewater treatment method, comprising: the sewage generated in the stone processing process first flows into a sedimentation tank, and a coagulant is added to the sewage in the sedimentation tank to accelerate the settlement of suspended solids in the stone sewage and increase the colloid and suspended solids in the sewage The suspended matter in the sewage forms stone mud at the bottom of the sedimentation tank, and the upper layer of clear water is filtered and overflows into the secondary sedimentation tank for secondary sedimentation. The bottom of the secondary sedimentation tank continues to form stone mud, and the upper layer is clear water. The upper clear water in the secondary sedimentation tank overflows to the clear water tank after being filtered, and the clear water in the clear water tank is reused. The stone mud at the bottom of the sedimentation tank and the secondary sedimentation tank is extracted through the pipeline and then treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com