Synthetic method of high-molecular-weight linear polyphenylene sulfide

A polyphenylene sulfide and synthesis method technology, applied in the field of synthesis of high molecular weight linear polyphenylene sulfide, can solve the problems of low yield, high toxicity of liquid bromine raw materials, cumbersome process routes, etc., and achieve high molecular weight and high purity , The effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

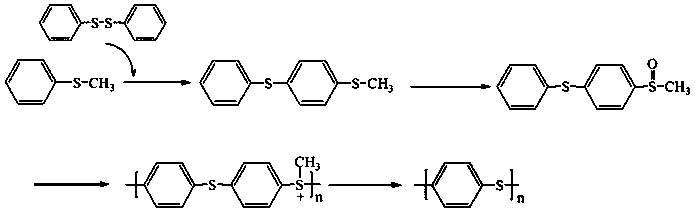

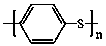

Method used

Image

Examples

Embodiment 1

[0032] Put 5.71g (0.046mol) of sulfide anisole, 4.36g (0.02mol) of diphenyl disulfide, and 10.81g (0.04mol) of potassium persulfate into the reaction bottle, and slowly add 6ml of it dropwise with a constant pressure dropping funnel Trifluoroacetic acid, continue to react at room temperature for 412 hours after the dropwise addition, the raw material diphenyl disulfide is consumed, add 300ml water to the system and stir for 30 minutes, extract three times with 50ml ethyl acetate, combine the organic phases, backwash with water, The organic phase was separated and dried with anhydrous sodium sulfate, filtered, and concentrated under reduced pressure to obtain a light yellow liquid. After column chromatography, 7.4 g of 4-(thiophenyl)sulfide anisole was obtained as a colorless transparent liquid with a yield of 81%. .

[0033] Put 4.64g (0.02mol) of 4-(thiophenyl)sulfide anisole and 20ml of acetonitrile into the reaction bottle, slowly add 16ml of hydrogen peroxide (30%) dropwis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com