Mineral insulated fire control cable

A control cable, mineral insulation technology, applied in the field of power cables, can solve the problems of environmental protection and flame retardant, difficult to meet the required requirements of fire resistance, produce harmful substances, cables cannot be energized, etc., to achieve strong fire resistance and ensure good integrity The effect of improving the safety operation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

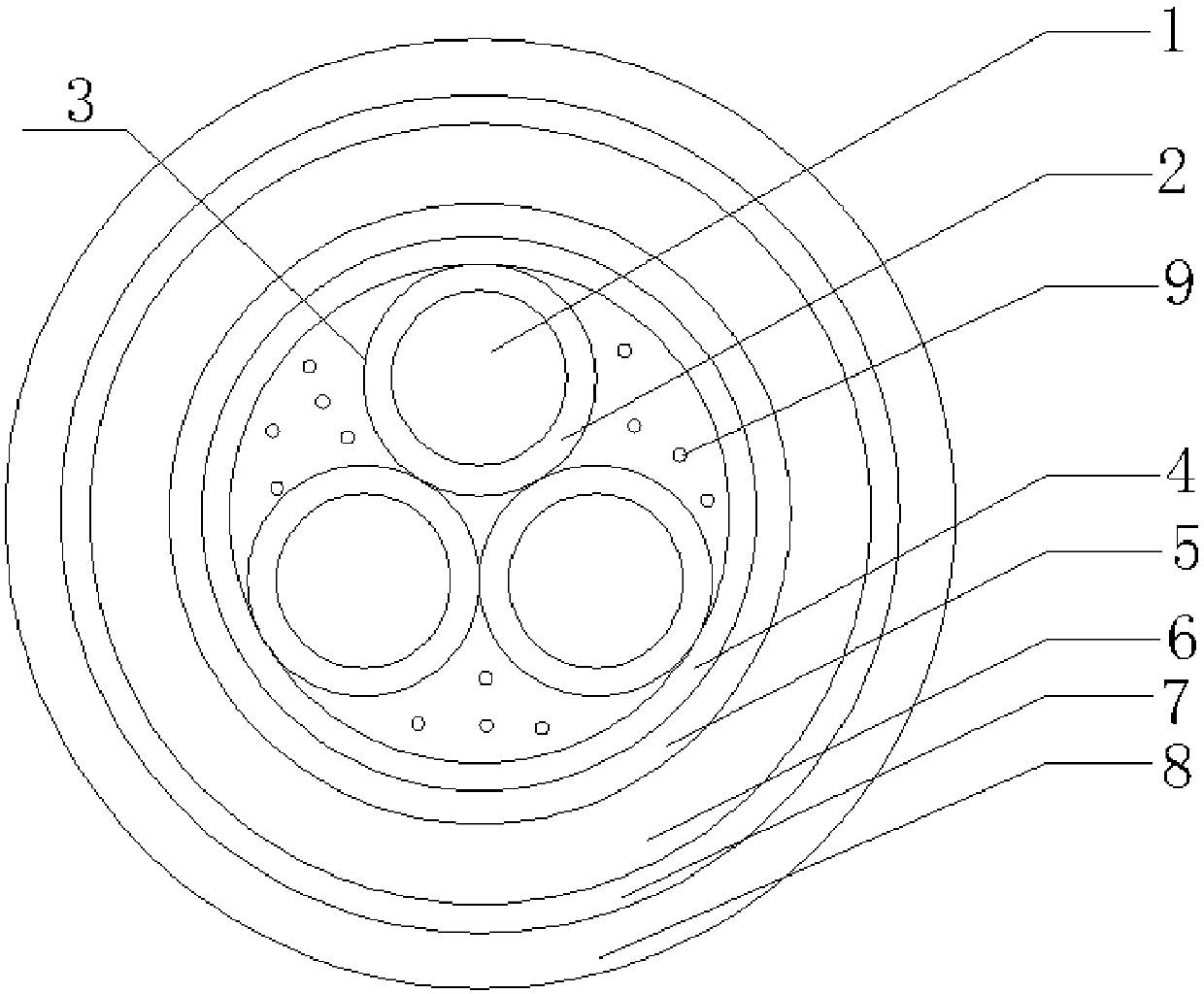

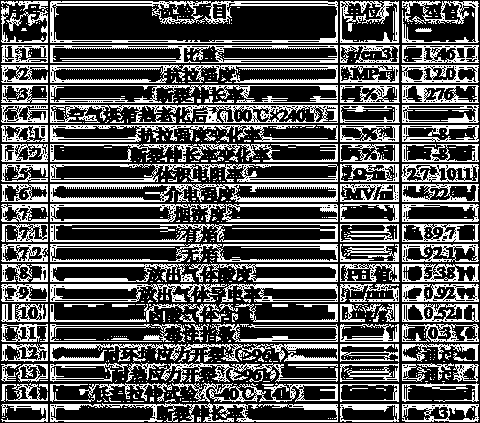

[0025] Embodiments 1-4: A mineral insulated fireproof control cable, including three round copper conductors 1, the outer surface of the round copper conductors 1 is covered with an insulating layer 2 to form a power core 3, and the three power cores 3 are twisted To form a cable core, an alkali-free glass fiber tape is wrapped around the outer surfaces of the three power cores 3 to form a tape layer 4, and the outer surface of the tape layer 4 is covered with a shielding layer 5 and an oxygen barrier layer 6 Wrapped on the outer surface of the shielding layer 5, the outer surface of the oxygen barrier layer 6 is covered with an armor layer 7, and the outer surface of the armor layer 7 is covered with a low-smoke flame-retardant polyolefin sheath layer 8. A number of alkali-free glass fiber filling ropes 9 are filled between the layer 4 and the cable core; the oxygen barrier layer 6 and the insulating layer 2 are composed of the following components by weight, as shown in Table...

Embodiment 1

[0031] The lubricant in Example 1 is stearic acid and its ester derivatives, the metal soap lubricant in Example 2, the saturated hydrocarbon lubricant in Example 3, and the silicon-based lubricant in Example 4.

[0032] The preparation method of the special ceramic halogen-free low-smoke flame-retardant polyolefin insulation material of the present invention comprises the following steps: 100 parts of ethylene-octene copolymer (POE) weighed in parts by weight, filler A, namely the ore method, is hydrogenated 150 parts of magnesium, 5 parts of filler B and zinc borate, 0.5 part of lubricant and stearic acid, 0.5 part of antioxidant KY405, and 10 parts of vitrified powder are put into the internal mixer and mixed until the material When the temperature is 120°C, the material is discharged and sent to the conical feeding hopper, which is introduced into the twin-screw extruder for melt extrusion, and after cold cutting (cooling and cutting), the special ceramic halogen-free and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com