Treatment device and method for wastewater containing ammonia nitrogen and phosphorus

A treatment device and treatment method technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of waste residue, high treatment cost, easy scaling and blockage, etc., to achieve Reduced processing costs, simple device structure, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

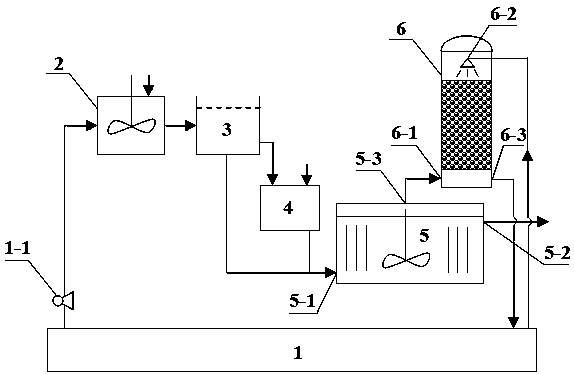

[0065] Such as figure 1 As shown, the device includes a waste water pool 1, a pH value adjustment unit 2, a head tank 3, an electrolyte batching device 4 and an electrolytic catalytic oxidation unit 5; the waste water pool 1 is connected to the pH value adjustment unit 2 through a water pump 1-1 The pH adjustment unit 2 is connected to the head tank 3; the head tank 3 is connected to the electrolyte batching device 4 and the water inlet 5-1 at the bottom of one end of the electrolytic catalytic oxidation unit 5; the electrolyte batching device 4 is connected to The water inlet 5-1 at the lower part of one end of the electrolytic catalytic oxidation unit 5 is connected; the water outlet 5-2 of the electrolytic catalytic oxidation unit 5 is arranged on the upper part of the other end of the electrolytic catalytic oxidation unit 5; the electrolytic catalytic oxidation unit 5 is a sealing device The exhaust port 5-3 at the top of the electrolytic catalytic oxidation unit 5 is conn...

Embodiment 1

[0068] Pump the ammonia nitrogen and phosphorus-containing waste water 1 in the waste water pool 1 into the pH value adjustment unit 2, adjust the pH value of the waste water to 10.1 with calcium hydroxide, and import the alkaline waste water into the high level tank 3 for storage. The tank 3 flows into the electrolyte dosing device 4, adding sodium chloride to prepare an electrolyte solution with a chloride ion concentration of 100g / L, and the remaining part of the alkaline wastewater in the electrolyte solution and the high level tank 3 is 0.03:1 in volume ratio (electrolytic catalytic oxidation The chloride ion concentration of the mixed liquid in the unit is 2.9g / L), and the mixed water inflow is 5m 3 / h, through the water inlet 5-1 at the bottom of one end of the electrolytic catalytic oxidation unit 5, mix and flow into the electrolytic catalytic oxidation unit 5, and the current density at the anode is 35mA / cm 2 , the voltage is 5V, the electrolytic catalytic oxidation ...

Embodiment 2

[0071] Pump the ammonia nitrogen-containing waste water 1 in the waste water pool 1 into the pH adjustment unit 2, adjust the pH value of the waste water to 11.5 with calcium hydroxide, and import the alkaline waste water into the head tank 3 for storage, and then, a part of the alkaline waste water is discharged from the head tank 3 Flow into the electrolyte dosing device 4, add sodium chloride to be mixed with the electrolyte solution with a chloride ion concentration of 130g / L, and the remaining part of the alkaline wastewater in the electrolyte solution and the head tank 3 is mixed at a volume ratio of 0.04:1 (in the electrolytic catalytic oxidation unit) The chloride ion concentration of the liquid is 5.0g / L), and the mixed water intake is 3m 3 / h, through the water inlet 5-1 at the bottom of one end of the electrolytic catalytic oxidation unit 5, mix and flow into the electrolytic catalytic oxidation unit 5, and the current density at the anode is 25mA / cm 2 , the voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com