Performance controllable silicon nitride ceramic implant and preparation method thereof

A technology of silicon nitride ceramics and implants, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of uncertain time bombs, etc., and achieve the effects of good bone ingrowth ability, crack resistance, and excellent friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

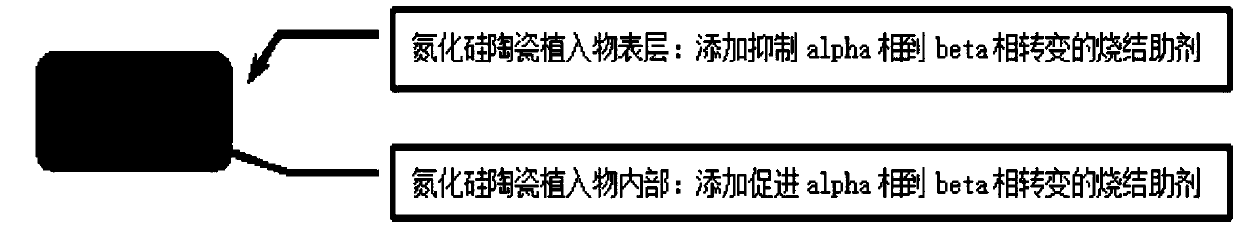

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a silicon nitride ceramic implant, comprising the steps of:

[0035] S1: Mix silicon nitride and additives with a mass ratio of (60-95): (5-40), and then perform ball milling, granulation, and drying in sequence to obtain the first composition; the mass of silicon nitride and additives The ratio can be 60:40, 70:30, 80:20, 90:10, 95:5;

[0036] Wherein, the additives include a first additive and a second additive whose mass ratio is (60-95):(5-40), and the first additive is selected from magnesium oxide, aluminum oxide, yttrium oxide, strontium oxide, cerium oxide, chromium oxide, A mixture of one or more of titanium carbide, titanium nitride and boron nitride; the second additive is selected from a mixture of one or more of erbium oxide, thulium oxide, ytterbium oxide and lutetium trioxide; the first The mass ratio of the additive to the second additive may be 60:40, 70:30, 80:20, 90:10, 95:5.

[0037] Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com