Method for separating and extracting amino acid mother liquor

An extraction method and amino acid technology, which are applied in the field of amino acid mother liquor treatment, can solve problems such as unfavorable treatment of large-scale mother liquor, high cost of culture medium raw materials, limited amount of waste water used, etc., and achieve good film hanging effect, simple and feasible method, and pollutant concentration. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The separation and extraction method of threonine mother liquor, it comprises the steps:

[0029] Extraction and separation of threonine by high performance liquid chromatography: to contain Na + The positive resin is a stationary phase adsorbent, to which the mother liquor of threonine is added, the chromatographic separation temperature is 65°C-85°C, and the flow rate is controlled at 80-85m 3 / h, for chromatographic separation, using water as the eluent, the flow rate is controlled at 90-95m 3 / h, to separate the residual sugar, pigment and inorganic salt in the mother liquor of threonine for the production of fertilizer; the liquid after chromatographic separation is evaporated and concentrated, and then centrifuged to obtain threonine crystals and waste liquid;

[0030] Candida utilis was inoculated into YPD liquid medium for cultivation to obtain Candida utilis seed liquid, and the cell concentration was 1×10 9 CFU / ml;

[0031] Lactobacillus casei was inoculate...

Embodiment 2

[0036] The separation and extraction method of amino acid mother liquor, it comprises the steps:

[0037] Extraction and separation of threonine by high performance liquid chromatography: to contain Na + The positive resin is a stationary phase adsorbent, to which the mother liquor of threonine is added, the chromatographic separation temperature is 65°C-85°C, and the flow rate is controlled at 80-85m 3 / h, for chromatographic separation, using water as the eluent, the flow rate is controlled at 90-95m 3 / h, to separate the residual sugar, pigment and inorganic salt in the mother liquor of threonine for the production of fertilizer; the liquid after chromatographic separation is evaporated and concentrated, and then centrifuged to obtain threonine crystals and waste liquid;

[0038] Candida utilis was inoculated into YPD liquid medium for cultivation to obtain Candida utilis seed liquid, and the cell concentration was 2×10 9 CFU / ml;

[0039] Lactobacillus casei was inoculate...

Embodiment 3

[0044] The threonine mother liquor used in the present invention is the raffinate after extracting threonine from the fermentation broth, and detects the indicators of pollutants in the threonine mother liquor before treatment, after chromatographic treatment and after biochemical treatment. For specific processes, refer to Example 1, See Table 1 for details:

[0045] Table 1

[0046]

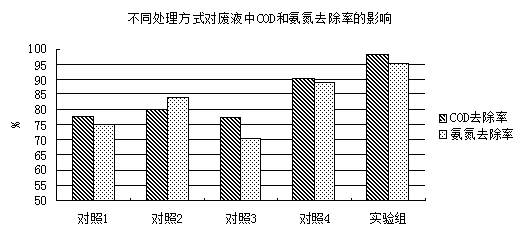

[0047] As shown in Table 1 above, after chromatographic treatment, the content of threonine in the waste liquid decreased significantly, a certain amount of threonine was extracted, the total yield increased, and the economic benefit was improved; the residual sugar, pigment and Inorganic salts can also be used in fertilizers; after biochemical treatment, the pollutants and crude protein content in the waste liquid are significantly reduced, and the treated liquid can be used as water source for field irrigation, reducing the environmental protection pressure of enterprises.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com