Preparing method and application of tungsten based nanoflower material

A nano-flower and tungsten-based technology is applied in the field of preparation of tungsten-based nano-flower materials, which can solve rare problems and achieve the effects of good repeatability, simple operation process, and good potential for large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

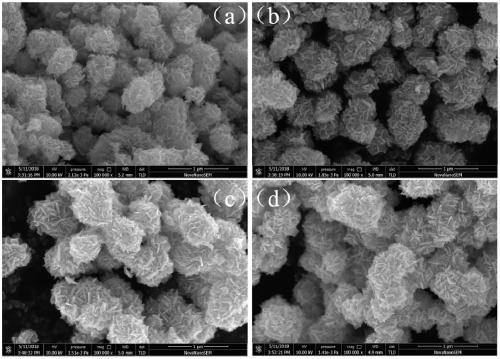

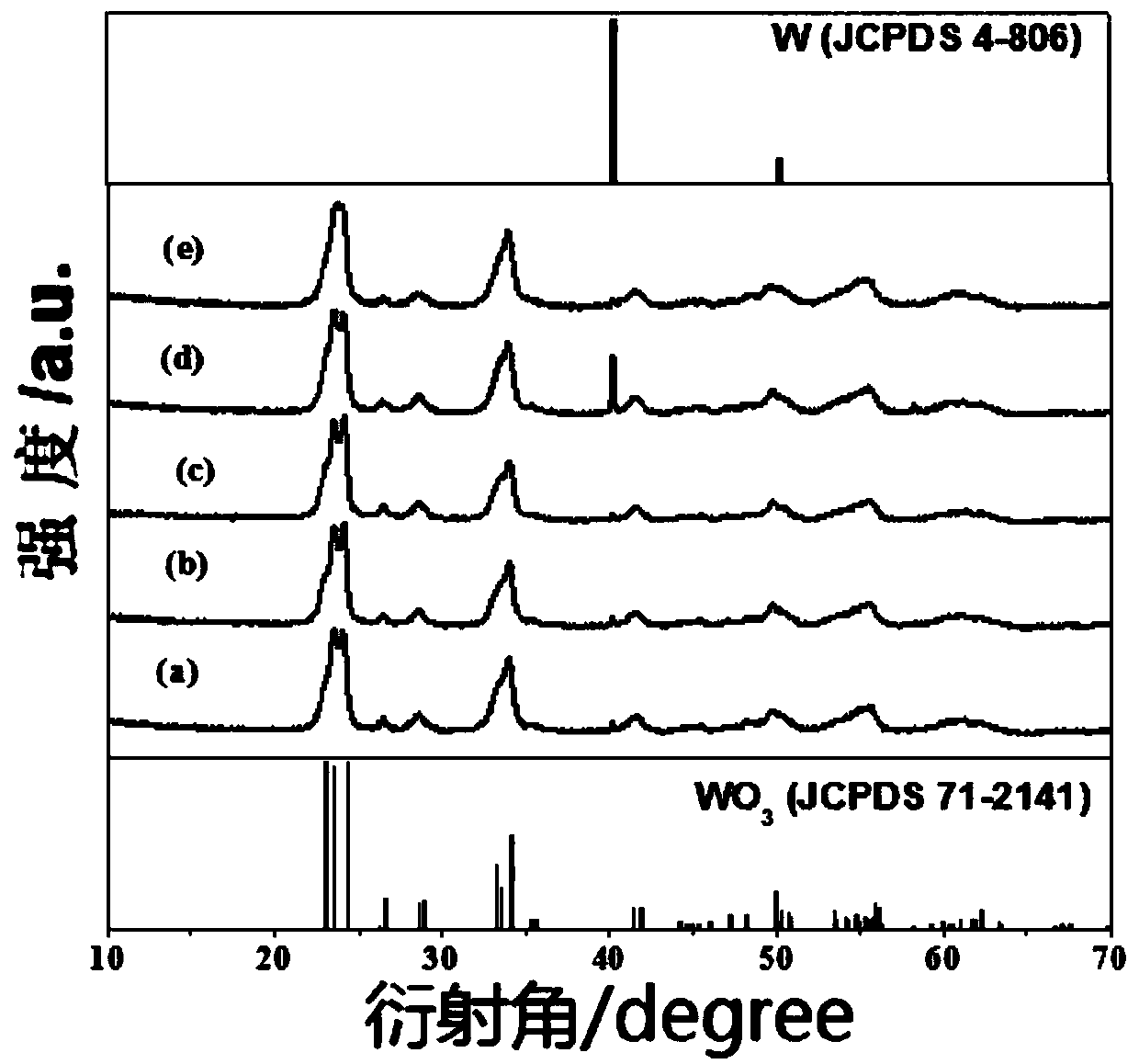

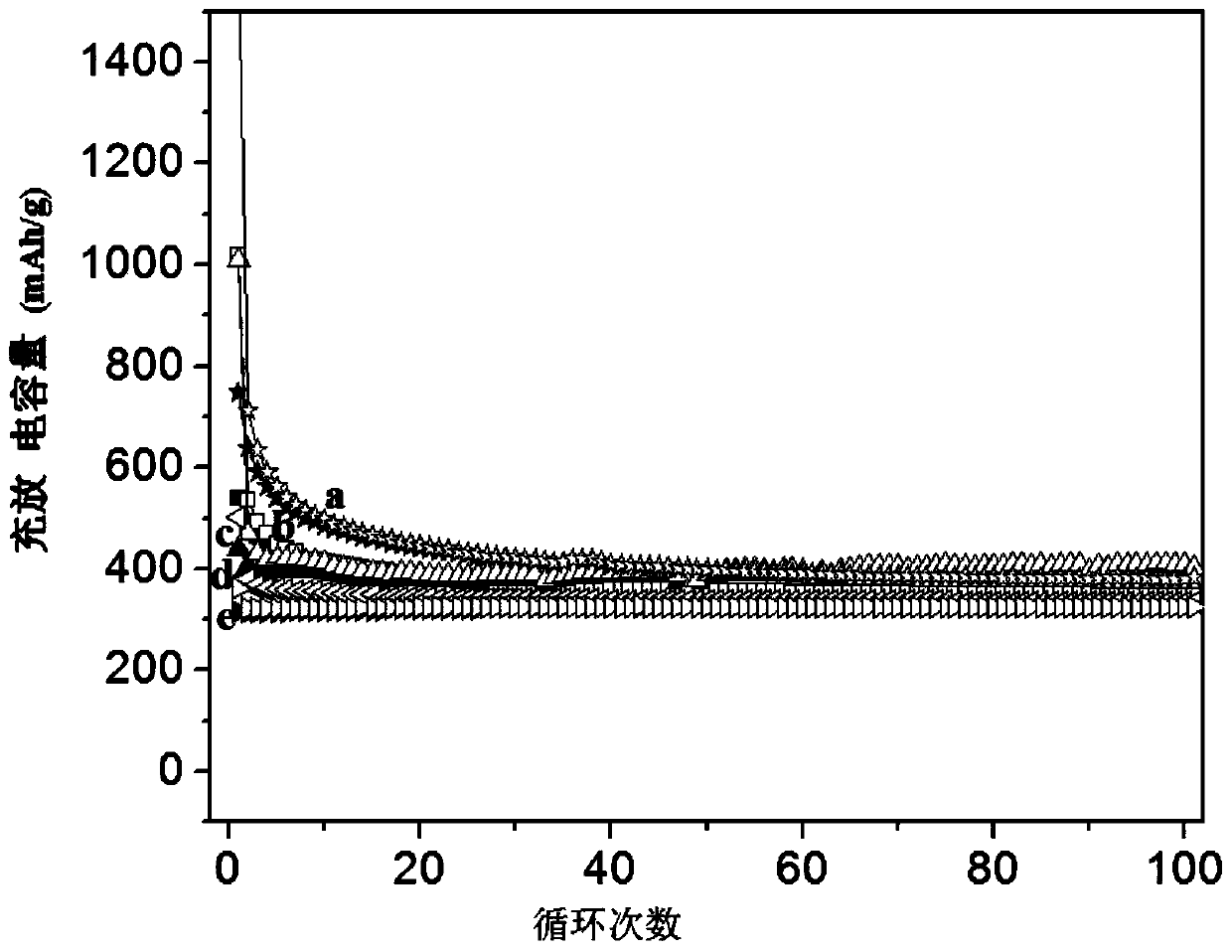

[0020] 50 g Cu and 50 g W metal powders and 0.5 g samarium chloride were wet ball milled for 2 h, and after vacuum drying, 50-200 nm rare earth doped Cu-W was prepared by variable current laser ion beam gas phase method Alloy nanospheres; the Cu-W alloy nanospheres were passed through H at a volume ratio of 1:1:1 2 O-H 2 o 2 -H 2 SO 4 The mixed solution was stirred at 60 °C for 12 h to remove Cu by liquid phase oxidation, and after filtration, washing and drying, rare earth doped W-WO 3 Composite material; W-WO doped with rare earth 3 The composite material was directly sintered at 350°C in an air atmosphere, and the samarium-doped tungsten-based nanoflower material with sheet-like abundant oxygen vacancies was prepared after calcination.

Embodiment 2

[0022] 50 g Cu and 50 g W metal powder and 1 g europium nitrate were wet ball milled for 2 h, and after sufficient vacuum drying, 100-500 nm rare earth doped Cu-W was prepared by variable current laser ion beam gas phase method Alloy nanospheres; the Cu-W alloy nanospheres were passed through H at a volume ratio of 1:1:1 2 O-H 2 o 2 -H 2 SO 4 The mixed solution was stirred at 60 °C for 12 h to remove Cu by liquid phase oxidation, and after filtration, washing and drying, rare earth doped W-WO 3 Composite material; W-WO doped with rare earth 3 The composite material was directly sintered at 450°C in an air atmosphere, and the europium-doped tungsten-based nanoflower material with sheet-like rich oxygen vacancies was prepared after calcination.

Embodiment 3

[0024] 5g Cu, 95 g W metal powder and 1 g Lanthanum Chloride were wet ball milled for 2 h, and after sufficient vacuum drying, 500-1 micron nm rare earth doped Cu was prepared by variable current laser ion beam gas phase method. -W alloy nanospheres; the Cu-W alloy nanospheres are passed through H at a volume ratio of 1:1:1 2 O-H 2 o 2 -H 2 SO 4 The mixed solution was stirred at 60 °C for 24 h to remove Cu by liquid phase oxidation, and after filtration, washing and drying, rare earth doped W-WO 3 Composite materials; the W-WO 3 Composite materials directly in Ar / H 2 The lanthanum-doped tungsten-based nanoflower material with sheet-like rich oxygen vacancies was prepared by sintering at 450°C under the atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com