Pre-lithiation method for lithium ion battery

A lithium ion battery and lithium powder technology, applied in the field of lithium ion batteries, can solve the problems of difficulty in controlling the degree of pre-lithiation, difficult to control, low density of lithium powder, etc., achieve controllable degree of pre-lithiation, ensure uniformity, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

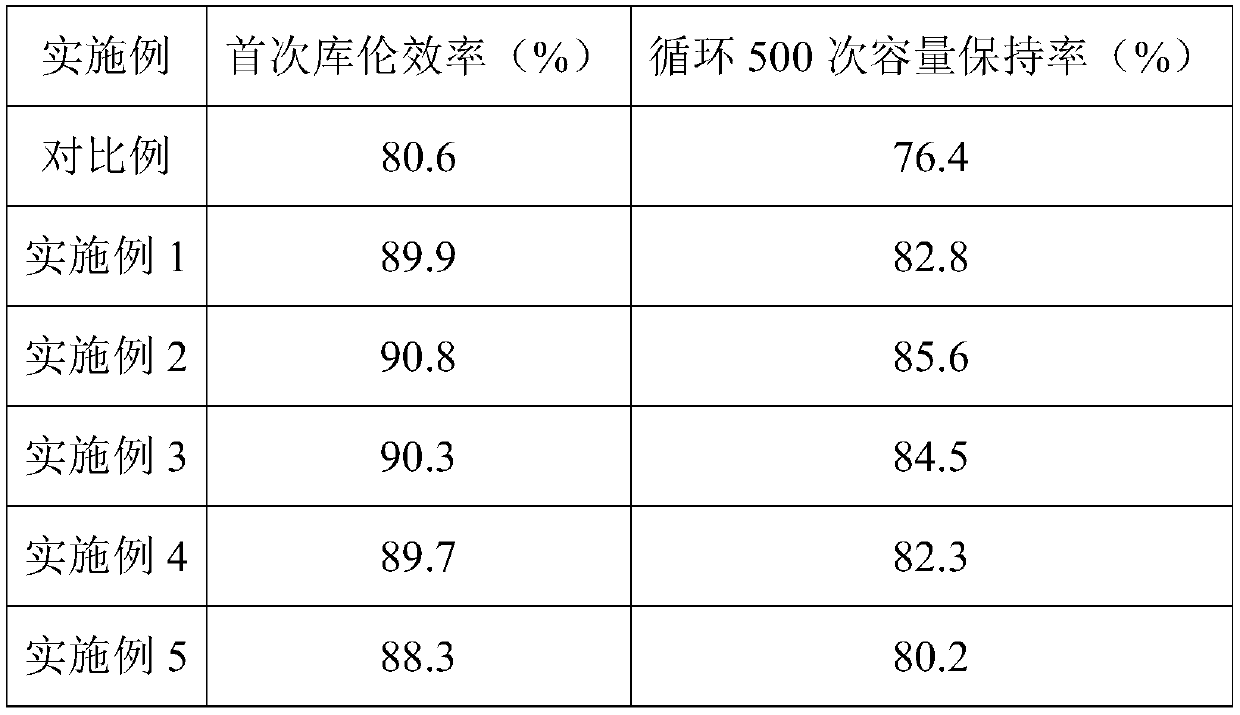

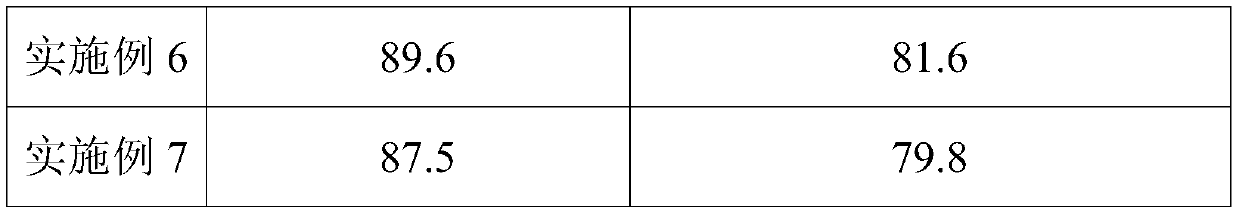

Examples

Embodiment 1

[0038] First, in an argon atmosphere, lithium powder (particle size is about 10um), polyethylene oxide powder, carbon nanotubes and lithium bis(trifluoromethylsulfonyl)imide according to the mass of 45:25:20:10 Put it into the mixing tank, and use mechanical stirring to stir at a speed of 60 rpm for 120 minutes to make it pre-mixed evenly, then raise the temperature to 100°C, and continue stirring for 120 minutes to obtain a multi-component mixed slurry. A small amount of solvent is added to adjust the slurry viscosity.

[0039] Secondly, the multi-component mixed slurry is coated on the surface of the negative electrode sheet of the lithium ion battery by spin coating, and after cooling to room temperature, a lithium-rich conductive coating with a thickness of about 5 um is obtained.

[0040] Finally, as in the comparative example, a 2032-type button battery was assembled in a glove box filled with argon gas according to the usual method of assembling batteries in the laborat...

Embodiment 2

[0042] First, in an argon atmosphere, the mixture of lithium powder (particle size about 50um), polyethylene glycol powder, Ketjen black, carbon fiber and lithium bistrifluoromethanesulfonylimide was mixed according to the ratio of 70:20:60:5. The mass ratio is added to the mixing tank, and the mechanical stirring method is used to stir at a speed of 60 rpm for 120 minutes to make it pre-mixed evenly, and then the temperature is raised to 80°C, and the stirring is continued for 120 minutes to obtain a multi-component mixed slurry. The slurry viscosity is adjusted by adding a small amount of solvent.

[0043] Secondly, the multi-component mixed slurry is coated on the surface of the negative electrode sheet of the lithium ion battery by brushing, and after cooling to room temperature, a lithium-rich conductive coating with a thickness of about 10 um is obtained.

[0044] Finally, as in the comparative example, a 2032-type button battery was assembled in a glove box filled with ...

Embodiment 3

[0046] First, in an argon atmosphere, lithium powder (particle size is about 10um), carbon fiber, polyacrylonitrile powder and lithium bisfluoroxanthimide are added to the mixing tank according to the mass ratio of 50:10:25:15. Stir at a speed of 60 rpm for 120 minutes by means of mechanical stirring to pre-mix evenly, then add the organic solvent dimethyl sulfoxide and continue stirring for 120 minutes to obtain a multi-component mixed slurry.

[0047] Secondly, the multi-component mixed slurry is coated on the surface of the negative electrode sheet of the lithium ion battery by dip coating, and after cooling to room temperature, a lithium-rich conductive coating with a thickness of about 10 um is obtained.

[0048] Finally, as in the comparative example, according to the method of assembling batteries commonly used in the laboratory, in a glove box filled with argon, it was assembled into a 2032-type button battery. After the electrolyte was injected, the lithium bisfluoroxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com