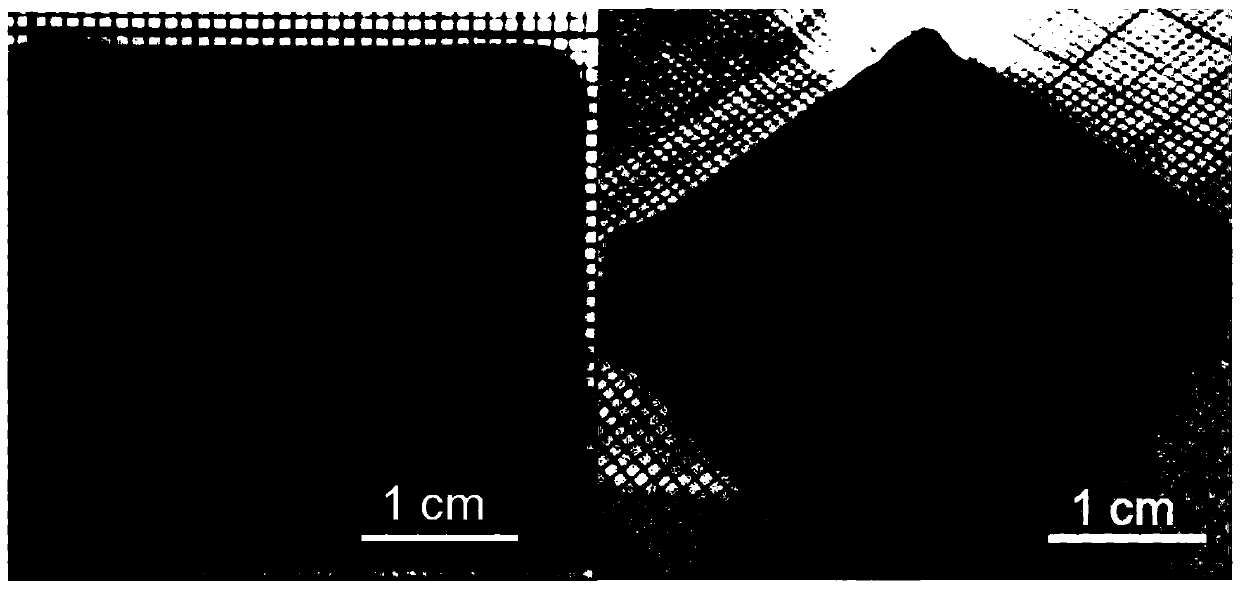

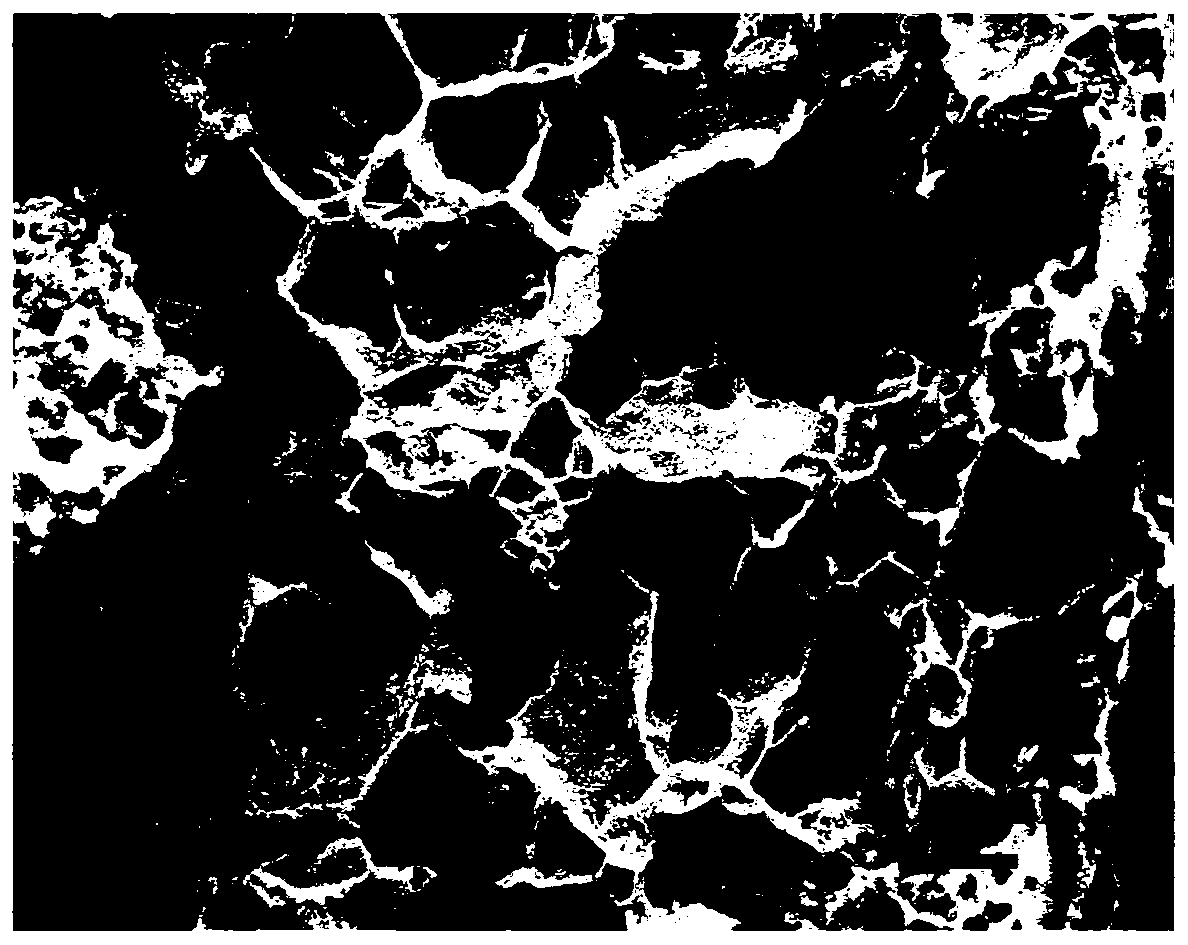

Photothermal drive type shape memory multiscale pore nanocomposite biological scaffold and preparation method thereof

A nano-composite and bio-scaffold technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of time-consuming materials, slow printing speed, etc., and achieve low production costs, fast stimulus response, and mild preparation process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) 2 parts by mass of graphene oxide are dispersed in 20 parts by volume of dichloromethane by ultrasonic treatment in an ice-water bath, and then add 20 parts by volume of a dichloromethane solution of low molecular weight carboxy-terminated polylactic acid (PLLA) (containing 2 parts by mass PLLA) mixed. The mixed solution was placed in an ice-water bath and mechanically stirred at 500 r / min for 15 minutes under the protection of nitrogen, then volatilized in a water bath at 30°C to remove dichloromethane, and then placed in a tube furnace under nitrogen atmosphere for calcination at 200°C for 24 hours to obtain hydrophobically modified Graphene oxide.

[0052] (2) Under the action of a 200W ultrasonic machine, 20 minutes of supersonication in an ice-water bath configure 3 parts by volume of dichloromethane suspension (i.e. oil phase), wherein polylactic acid-trimethylcarbonate copolymer (lactic acid, trimethylene carbonate) The molar ratio is 70:30, the molecular we...

Embodiment 2

[0056] (1) 4 parts by mass of graphene oxide are dispersed in 40 parts by volume of dichloromethane by ultrasonic treatment in an ice-water bath, and then add 20 parts by volume of a dichloromethane solution of low molecular weight carboxy-terminated polylactic acid (PLLA) (containing 2 parts by mass PLLA) mixed. The mixed solution was placed in an ice-water bath and mechanically stirred at 500 r / min for 15 minutes under the protection of nitrogen, then volatilized in a water bath at 30°C to remove dichloromethane, and then placed in a tube furnace under nitrogen atmosphere for calcination at 200°C for 24 hours to obtain hydrophobically modified Graphene oxide.

[0057] (2) Under the action of a 200W ultrasonic machine, 20 minutes of ultrasonication in an ice-water bath is used to configure 4 parts by volume of dichloromethane suspension (ie, oil phase), wherein polylactic acid-trimethylcarbonate copolymer (molecular weight is 5 × 10 4 g / mol, wherein the mol ratio of lactic a...

Embodiment 3

[0060] (1) 2 parts by mass of graphene oxide are dispersed in 20 parts by volume of dichloromethane by ultrasonic treatment in an ice-water bath, and then add 20 parts by volume of a dichloromethane solution of low molecular weight carboxy-terminated polylactic acid (PLLA) (containing 2 parts by mass PLLA) mixed. The mixed solution was placed in an ice-water bath and mechanically stirred at 500 r / min for 15 minutes under the protection of nitrogen, then volatilized in a water bath at 30°C to remove dichloromethane, and then placed in a tube furnace under nitrogen atmosphere for calcination at 200°C for 24 hours to obtain hydrophobically modified Graphene oxide.

[0061] (2) Under the action of a 200W ultrasonic machine, ultrasonically set 5 parts by volume of dichloromethane suspension (i.e. oil phase) in an ice-water bath for 20min, in which polylactic acid-trimethylcarbonate copolymer (molecular weight 5.3×10 4 g / mol, wherein the molar ratio of lactic acid and trimethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com