Preparation method of sodium titanium phosphate double-nano carbon in anode material of sodium-ion battery

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effect of improving high rate performance and cycle stability, strong interface bonding, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

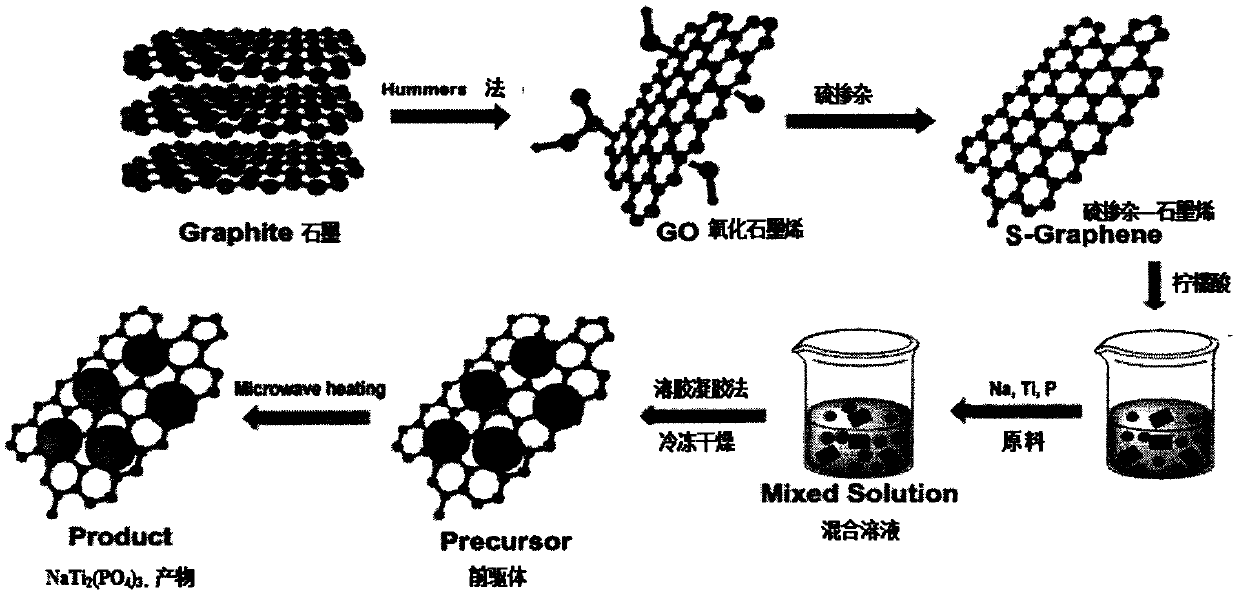

[0024] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a sodium titanium sodium phosphate double nanocarbon as the negative electrode material of a sodium ion battery, comprising the following steps:

[0025] (1) Preparation of graphene oxide

[0026] Using high-quality flake graphite as the starting material, graphene oxide was prepared by the improved Hummers method.

[0027] (2) Preparation of sulfur-doped graphene

[0028] Disperse the obtained graphene oxide in ethanol solution at a certain concentration, add diphenyl disulfide dopant after ultrasonic dispersion and magnetic stirring for a certain period of time, then magnetically stir to a dry state under specific temperature conditions and fill it with argon High-temperature heat treatment in a tube furnace for a certain period of time. Finally, the sulfur-doped graphene product was washed several times with deionized water and ethanol, and placed in an oven for dryi...

Embodiment

[0035] S1, graphene oxide preparation:

[0036] Add 1.5g of flake graphite with a particle size of 300 mesh, 0.75g of NaNO to a 250mL beaker 3 , 35mL concentrated sulfuric acid, placed in an ice-water bath at 0-4°C for 1.5-3 hours, then slowly added 4.5g KMnO 4 , keep the ice-water bath for 2 hours, then transfer to a water bath at 35°C, react for 2 hours, slowly add 50mL of distilled water to the beaker to dilute, and finally add 7.5mL of 30% hydrogen peroxide to the beaker to obtain golden yellow Precipitation is graphite oxide;

[0037] S2. Let the beaker stand for 1 to 2 hours until the graphite oxide precipitates to the bottom of the beaker, pour off the supernatant, take the graphite oxide precipitate and wash it with 5% hydrochloric acid solution for several times, wash it with distilled water until the solution is neutral, and centrifuge Separation, and drying the obtained graphite oxide precipitate in an 80°C drying oven for 24 hours;

[0038] S3. Take 100 mg of dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com