Bionic polymer and method for preparing durable double-bionic polymer coating and application thereof

A polymer coating and polymer technology, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of large polydopamine aggregate size, heavy coating color, and limited applications , to achieve the effects of good anti-biological pollution performance and bactericidal performance, improved coating stability, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of durable double biomimetic polymer coating of the present invention comprises the following steps:

[0047] Step 1, preparation of biomimetic polymers:

[0048] A1: According to the mole percentage, (1~90): (9~60): (1~70) will respectively contain the (meth)acrylic acid of zwitterionic group W, amino hydrochloride S and quaternary ammonium cationic group T The ester monomer is dissolved in the solvent, the mass percentage of the (meth)acrylate monomer and the solvent is (4-20): (80-96), and the monomer mixture is obtained;

[0049] B1: According to the mass percentage of initiator and (meth)acrylate monomer (0.1-5.0): (95.0-99.9), the initiator is dissolved in the solvent to obtain an initiator solution;

[0050] C1: Mix the monomer mixed solution and the initiator solution according to the mass percentage of (70-95): (5-30), mix them evenly, transfer them to the constant pressure dropping funnel, and use 20%-50% / The feed rate of 1 hour is ad...

Embodiment 1

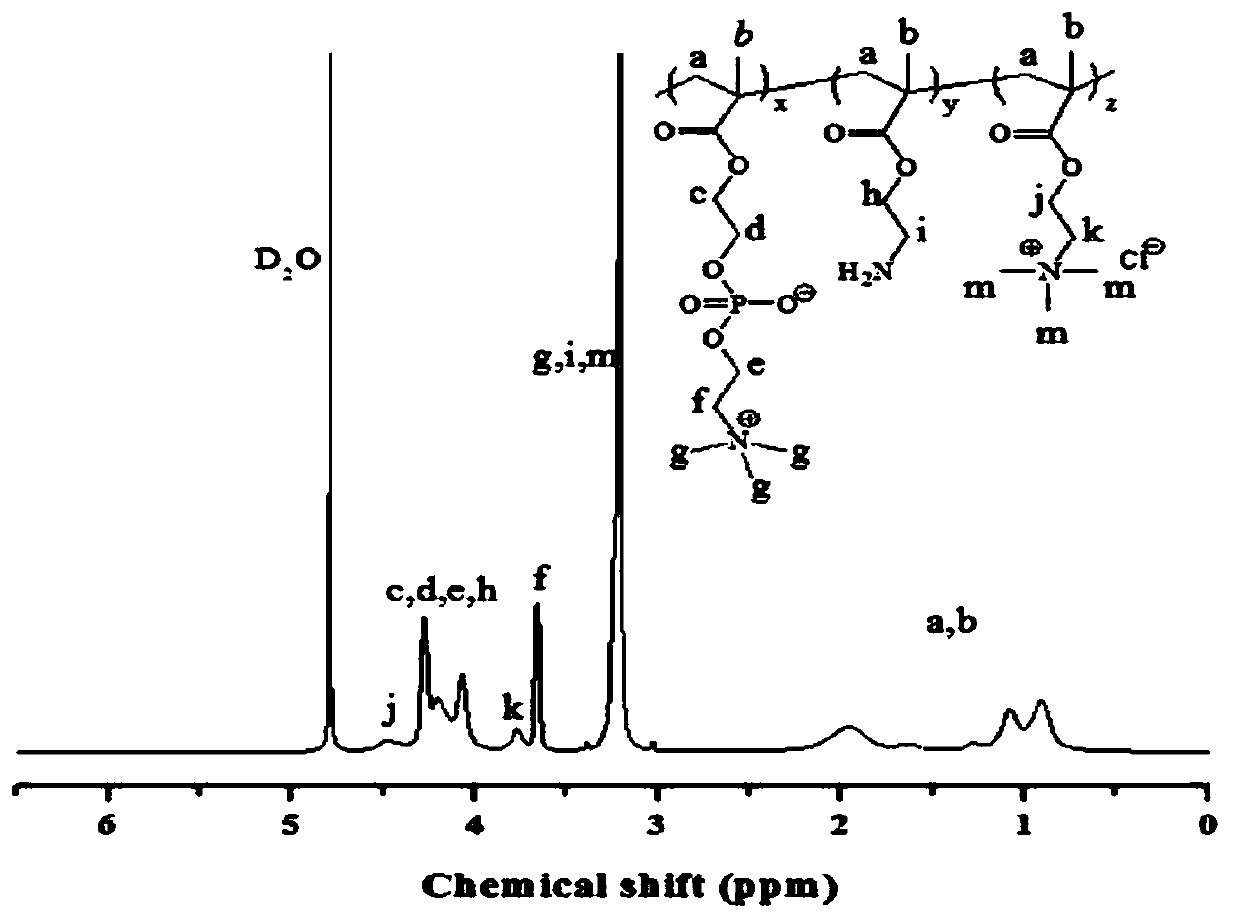

[0063] (Meth)acrylic acid ester copolymer (1 ) preparation:

[0064] With 2-methacryloyloxyethylphosphorylcholine (MPC), 2-aminoethylmethacrylate hydrochloride (AEMA) and methacryloyloxyethyltrimethylammonium chloride (TMA) as monomer, potassium persulfate (K 2 S 2 o 8 ) is a free radical initiator; take by weighing 5.31g (18mmol) MPC, 1.85g (11mmol) AEMA and 1.48g (7mmol) TMA respectively according to MPC, AEMA and TMA mole percentage feed ratio 50:30:20, then according to mass percentage Dissolve three kinds of (meth)acrylate monomers in deionized water at a ratio of 4:96 to obtain a monomer mixture; weigh 0.08541 g of Potassium sulfate is dissolved in deionized water to obtain an initiator solution; the monomer mixed solution and the initiator solution are mixed uniformly according to the mass percentage of 80:20, and transferred to a constant pressure dropping funnel. In a three-necked bottle equipped with a thermometer and a constant pressure dropping funnel, add 20 ...

Embodiment 2

[0066] Using the same polymerization method as in Example 1, with MPC, N-(3-aminopropyl) methacrylic acid hydrochloride (DPMA) and methacryloxyethyl dimethyl benzyl ammonium chloride (BDA) As a monomer, prepare a (meth)acrylic ester biomimetic polymer (2) containing phosphorylcholine zwitterions, amino hydrochloride and dimethyl benzyl ammonium chloride cations in side groups, only MPC, DPMA and BDA The molar percentage feeding ratio is 90:9:1, and the feeding amount is respectively 5.38g (18mmol) MPC, 0.36g (1.8mmol) DPMA and 0.06g (0.2mmol) BDA, and then three kinds of (formazan Base) acrylate monomer was dissolved in ethanol to obtain a monomer mixture; according to the mass percentage of initiator and (meth)acrylate monomer being 0.1:99.9, 0.0064g of azobisisobutyronitrile was weighed and dissolved in ethanol , to obtain an initiator solution; the monomer mixed solution and the initiator solution were mixed uniformly according to the mass percentage of 70:30, and transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com