Preparation method and application of a copper foil-loaded sodium-ion battery negative electrode material

A technology for sodium ion batteries and negative electrode materials, which is applied in the manufacture of electrodes, battery electrodes, and electrolyte storage batteries. Effect of initial discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

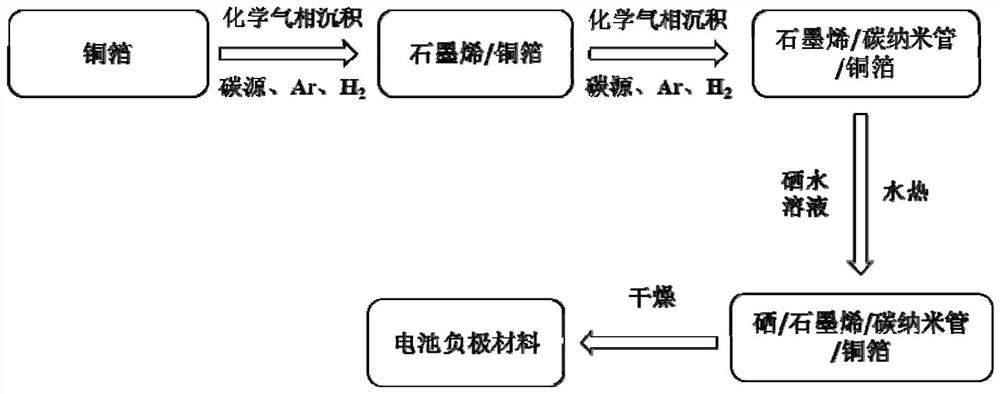

[0027] The preparation method of a copper foil-supported sodium ion battery negative electrode material provided by the present invention, the specific steps are as follows:

[0028] Step 1: Preparation of graphene film

[0029] Using copper foil as a template, the graphene film is grown by chemical vapor deposition process. The growth process conditions are: the carbon-containing precursor is used as the growth carbon source, the reaction temperature is 850-1050°C, the reaction time is 0.1-3h, and the flow rate of the carbon-containing precursor is 0.1- 150mL / min, argon flow rate 100-500mL / min, hydrogen flow rate 50-400mL / min;

[0030] Step 2: Growing Carbon Nanotubes on Graphene Film

[0031] Immerse the graphene / copper foil obtained in step 1 into a solution containing a catalyst precursor, then put it into a tube furnace and heat it to the growth temperature under a mixed atmosphere of argon and hydrogen, and use a chemical vapor deposition process to grow carbon nanotube...

Embodiment 1

[0044] (1) Preparation of materials

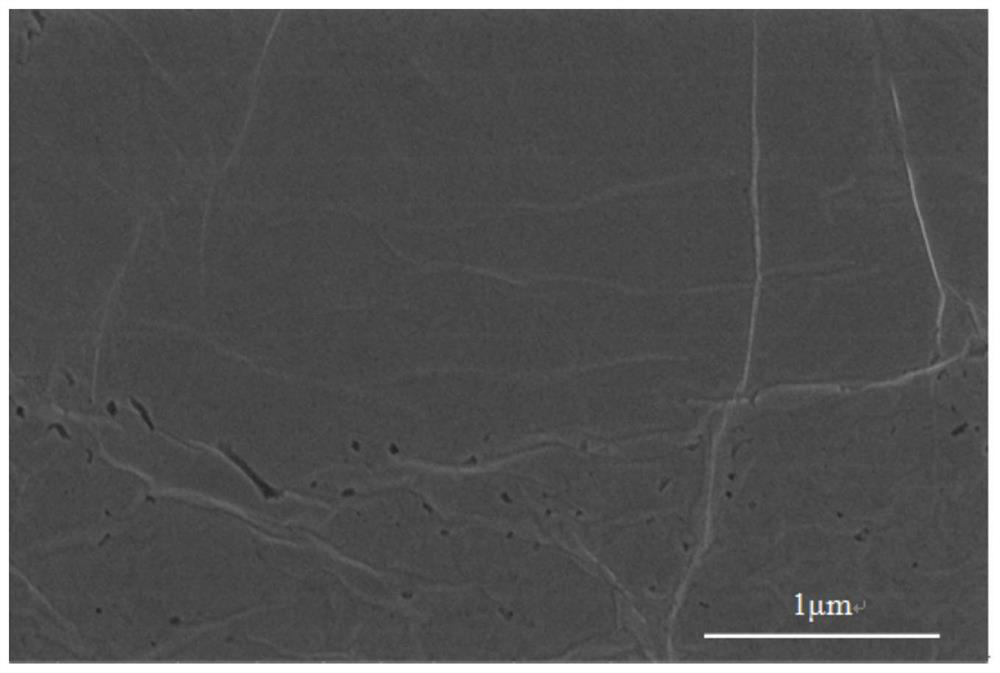

[0045] Using copper foil as a template, graphene is grown by chemical vapor deposition process. The process conditions are: methane as carbon source, reaction temperature 900°C, methane 80mL / min, argon flow 300mL / min, hydrogen flow 400mL / min, reaction time 20min Then cool down with the furnace to obtain graphene / copper foil.

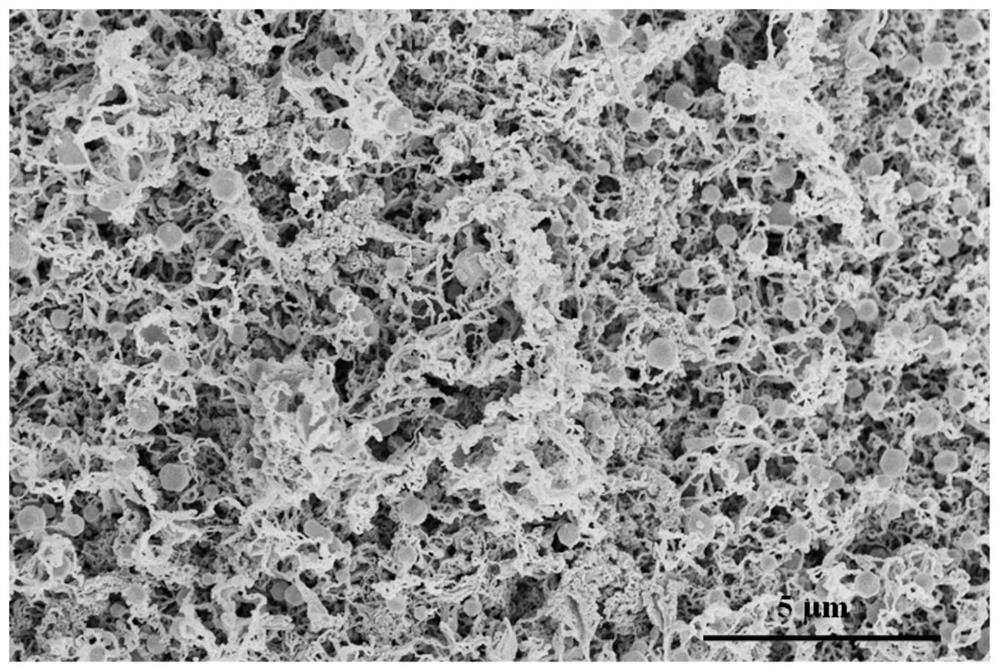

[0046] The graphene / copper foil was immersed in an aqueous solution containing ferrous sulfate (1g / mL), and then placed in a tube furnace to grow carbon nanotubes by chemical vapor deposition. The process conditions were: the growth temperature was 1000 °C, and the ethanol The carbon source is injected into the quartz tube by injection, the injection rate is 0.2mL / min, the flow rate of argon gas is 400mL / min, the flow rate of hydrogen gas is 100mL / min, and the graphene / carbon nanotube / copper foil is grown for 20min.

[0047] Preparation of selenium solution: deionized water 50mL, selenium 1.5g, fully stirred on a ma...

Embodiment 2

[0052] Using copper foil as a template, graphene is grown by chemical vapor deposition process. The process conditions are: methane as carbon source, reaction temperature 900°C, methane 90mL / min, argon flow 400mL / min, hydrogen flow 200mL / min, reaction time 20min Then rapidly cool down to room temperature at a cooling rate of 10°C / min to obtain graphene / copper foil. Compared with Example 1, the number of graphene film layers in Example 2 is lower. Subsequent steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com