A kind of production technology of glucose sodium chloride injection

A glucose sodium chloride and production process technology, which is applied in the field of glucose sodium chloride injection production technology, can solve the problem of affecting the production efficiency and quality safety of glucose sodium chloride injection, the residue of activated carbon particles and the high content of other particles, and the residue of activated carbon Particles cannot be completely removed and other problems, to achieve the effect of optimizing process production efficiency and finished product qualification rate, reducing bacterial endotoxin content, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

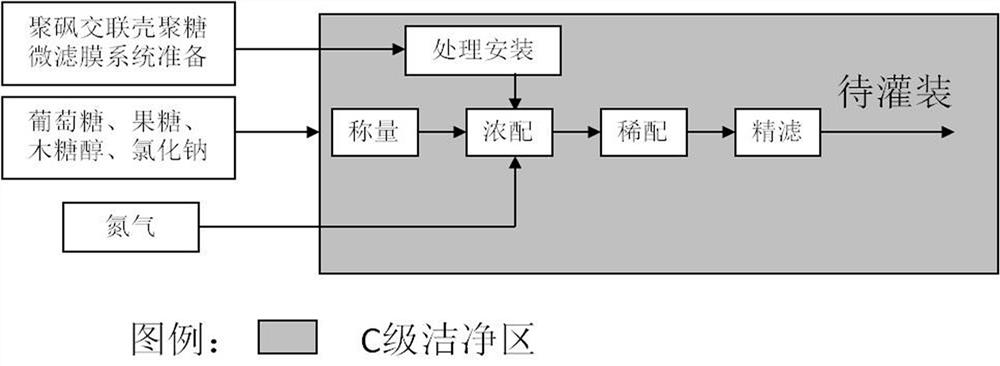

[0042] A kind of glucose sodium chloride injection production technology, comprises the following steps:

[0043] Step 1. Weighing: Calculate the required amount of glucose, fructose, xylitol, and sodium chloride according to the total amount of preparation, and then accurately weigh, one person weighs and one person checks;

[0044] Step 2. Concentrated preparation: add 25% of the total amount of water for injection into the concentrated preparation tank, control the temperature at 80±5°C, pass nitrogen, put in glucose, fructose, xylitol, and sodium chloride, and pass nitrogen to keep warm Stir and circulate for 30 minutes, filter through the polysulfone cross-linked chitosan microfiltration membrane system, and check that the foreign matter in the liquid is qualified;

[0045] Step 3. Dilute dispensing: Rinse the concentrated dispensing tank and drug delivery pipeline with about 1000L of water for injection for three times. After the rinse water is filtered, send it to the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com