Isolation and purification of a hydrolyzed milk allergy source beta-lactoglobulin protease

A milk allergy and protease technology, applied in the biological field, can solve the problems of limited β-lactoglobulin desensitization effect, influence on milk flavor, complex hydrolysis process, etc., and achieve stable protease properties, short fermentation period and simple fermentation medium. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The separation and purification of embodiment 1 bacillus subtilis

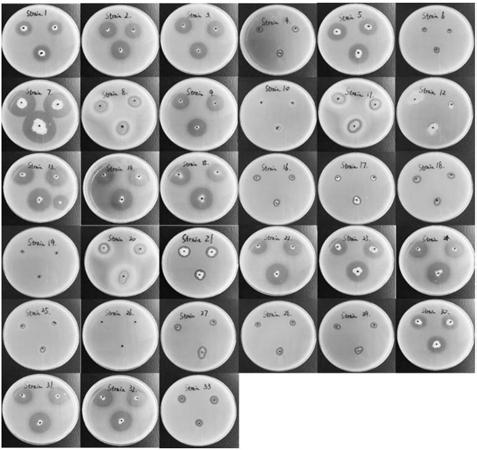

[0057] The bacterial strain used in this invention is screened from Wuxi Mashan Pasture, obtained more than 3000 strains of wild bacteria from soil and water, and then obtained 30 strains capable of degrading protein by screening with fat-free milk medium ( figure 1 ), and then directly react the crude enzyme produced by the strain with β-lactoglobulin, and finally determine that Strain 7 (S7) has the best effect on β-lactoglobulin, and then through 16S rDNA and functional gene gyrA sequencing and calibration, determine S7 is Bacillus subtilis, which was preserved in the China Center for Type Culture Collection on September 27, 2016, with the strain preservation number M2016532, the preservation address is the Wuhan University Collection Center, and the classification is named Bacillus subtilis.

Embodiment 2

[0058] The mensuration of embodiment 2 bacillus subtilis performance

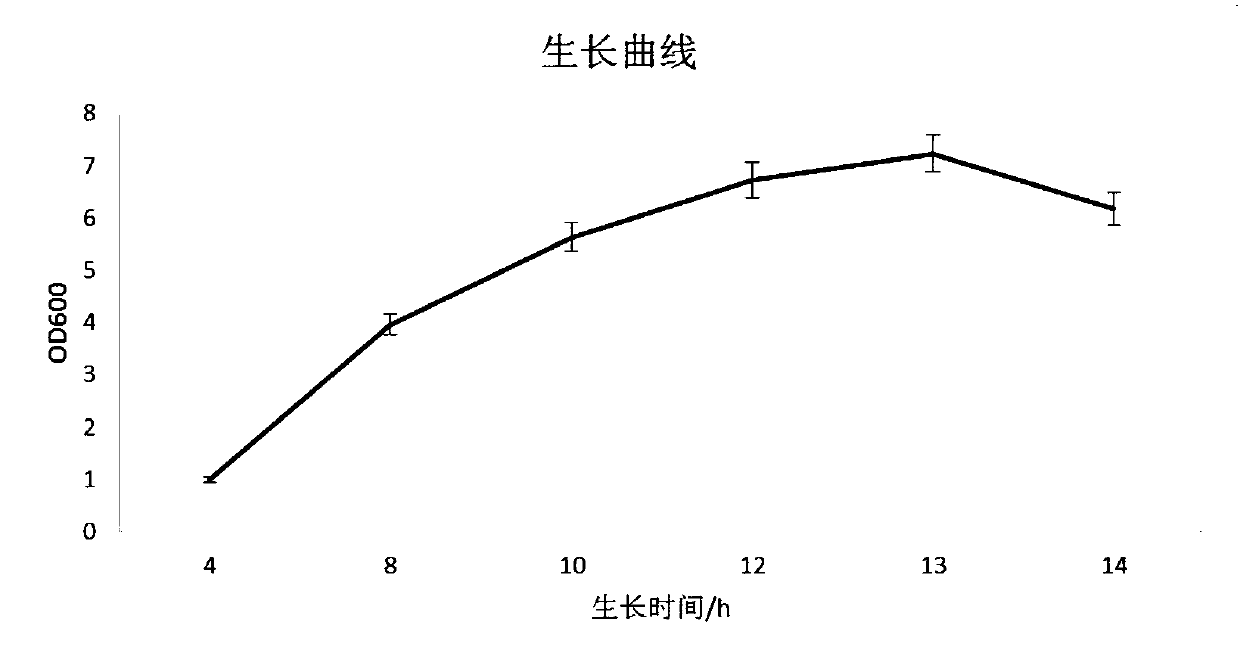

[0059] After the activation of bacterial strain S7, the inoculation amount of 2% (v / v) was transferred to a 250mL Erlenmeyer flask with 50mL of AM medium in each bottle, and cultured on a shaker at 220r / min at 37°C. Samples were taken every 4h in the early stage. Take a sample every 2h, measure the OD value at 600nm wavelength with a spectrophotometer, take time as the abscissa, OD 600 The value is the ordinate, draws the growth curve of Bacillus subtilis S7, and does three groups of parallel experiments ( figure 2 ). It can be found that the strain can reach a stable phase in about 12 hours and grow very rapidly.

Embodiment 3

[0060] Production and separation and purification of embodiment 3 protease

[0061] (1) Inoculate a single colony of Bacillus subtilis S7 into AM liquid medium with an inoculation needle, and cultivate it at 37°C and 220rpm for 12h;

[0062] (2) Inoculate the logarithmic phase seed solution in the AM liquid medium in the PDA liquid medium according to the inoculation amount of 2% by volume, and cultivate the medium for 12 hours at 37° C. at 220 rpm;

[0063] (3) Centrifuge the fermented liquid, collect the supernatant of the fermented liquid to be the crude enzyme liquid, and the enzyme activity is 37.32 U / mL.

[0064] (4) Ferment and cultivate Bacillus subtilis S7 to obtain the crude enzyme liquid, and use a gradient precipitation of ammonium sulfate acid with a mass fraction of 60% to precipitate the crude enzyme liquid, then resuspend the precipitate with pH 8.0, 50 mM phosphate buffer, dialyze, and use pH 8.0, 50mM phosphate buffer to equilibrate Q Sepharose fast-flow ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com