Method for preparing nucleases P1 by using fossilized penicillium citrinum

A Penicillium citrinum, nuclease technology, applied in biochemical equipment and methods, microorganism-based methods, immobilized on or in inorganic carriers, etc. Complex, carrier recovery loss and other problems, to shorten the fermentation cycle, improve production intensity and equipment utilization, improve the effect of transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of Example 1 Porous Network Carrier Material

[0059] Carry out corresponding chemical modification to the selected porous mesh material, said chemical modification comprises the following steps:

[0060] 1. Chemical modification of polyurethane foam sponge immobilization material: get polyurethane foam sponge 20g, drop in the sodium hydroxide aqueous solution of 2L epichlorohydrin (the mass fraction of epichlorohydrin and sodium hydroxide is respectively 10%, 5% ), stirred at room temperature for 12h, then washed to neutrality with deionized water to obtain a hydroxylated polyurethane foam sponge; the obtained hydroxylated polyurethane foam sponge was dropped into 1.5L mass fraction of 12% polyethyleneimine aqueous solution, After stirring and soaking for 8 hours, wash with deionized water until no polyethyleneimine is adsorbed on the surface to obtain a polyurethane foam sponge immobilized material with primary amine grafted arms.

[0061] 2. Chemical mod...

Embodiment 2

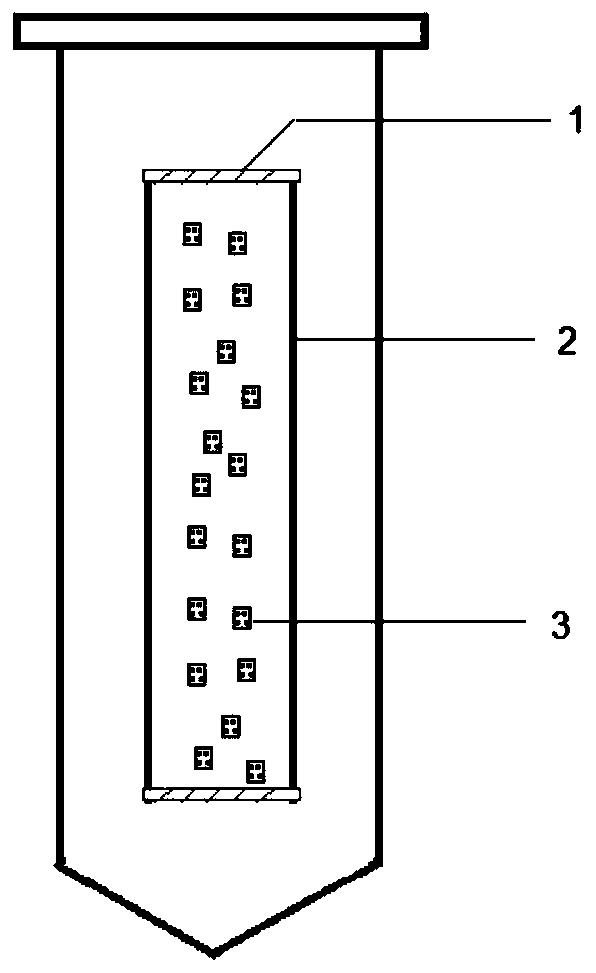

[0065] Example 2 The immobilized fermentation production of nuclease P1 in a high-throughput shaker

[0066] The soft fiber filler was chemically modified according to the method described in Example 1, and the carrier before and after the modification was used for immobilized fermentation of Penicillium citrinum in a high-throughput shaker at a filling rate of 4-6 g / L.

[0067] Cultivate the Penicillium citrinum strain on the wort slope at 28-30°C for 5-7 days for activation, wash the Penicillium citrinum slope fully with sterile water to obtain a spore suspension, and transfer it to a liquid fermentation medium ( Components: glucose 50g / L, peptone 5g / L, potassium dihydrogen phosphate 0.04g / L, dipotassium hydrogen phosphate 0.04g / L, magnesium sulfate 0.05g / L, calcium chloride 0.05g / L, zinc sulfate 0.05g / L, pH5-7) and immobilized carrier in a high-flux shaker reactor at 28-30°C, 200rpm, 0.05-0.5m 3 Repeated batches of fermentation culture of Penicillium citrinum were carried...

Embodiment 3

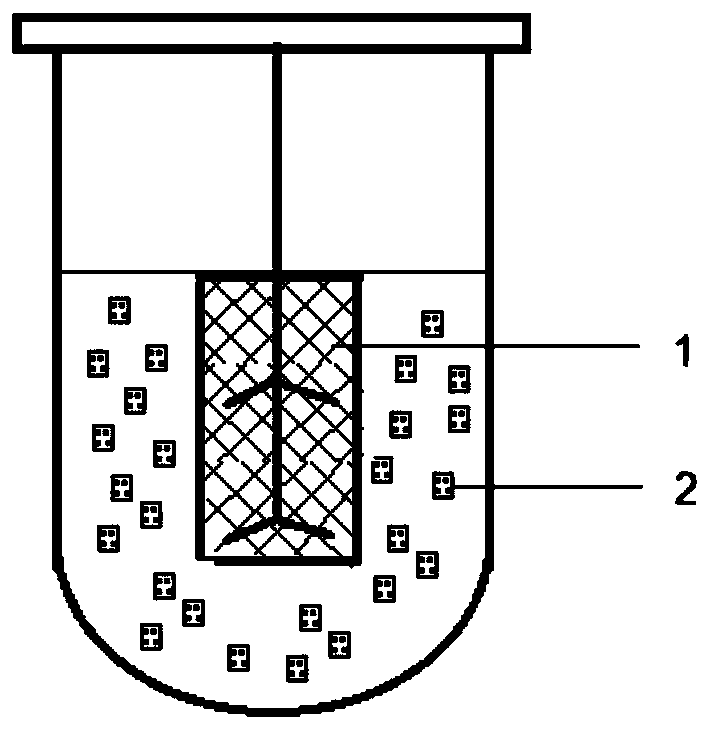

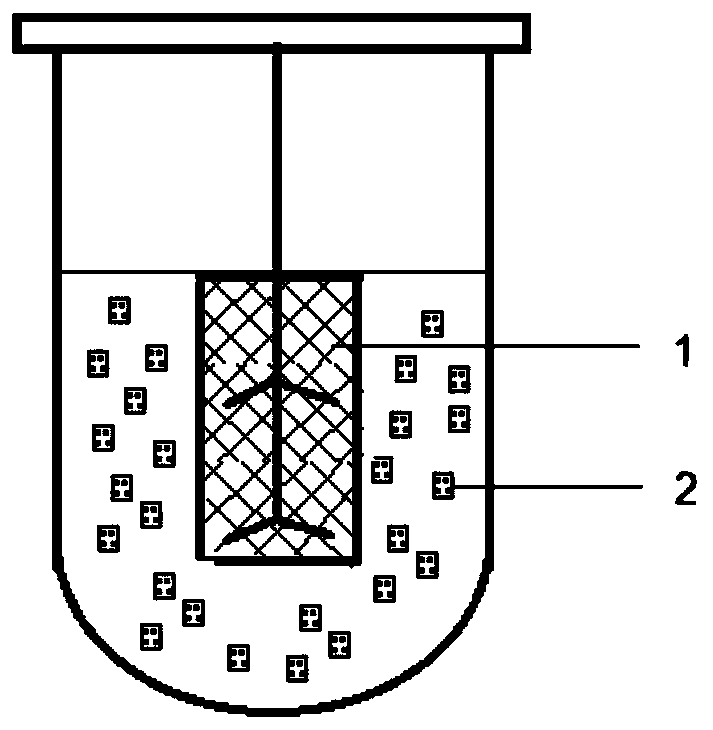

[0068] The immobilized fermentation production of nuclease P1 in the mechanical stirring tank of embodiment 3

[0069] Chemically modify the biologically active filler according to the method described in Example 1, fill it in an NBS tank with a filling capacity of 6 to 10 g / L, and carry out the immobilized fermentation test of Penicillium citrinum. The fixation method is as follows: figure 1 shown.

[0070] The preparation process of Penicillium citrinum seeds and the fermentation medium were the same as those in the high-throughput shaker fermentation experiment. During the fermentation process of the NBS tank, the rotation speed is 200rpm, and the ventilation volume is 0.2-1.0m 3 / h, pH 5-7, culture temperature 28-32°C, liquid volume 50%. Monitor the residual sugar and enzyme activity of the fermentation broth. When the activity of nuclease P1 in the fermentation broth no longer increases or decreases, remove all the fermentation broth and add the same volume of fresh med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com