Petal-shaped molybdenum disulfide two-dimensional crystal material as well as preparation method and application thereof

A two-dimensional crystal, molybdenum disulfide technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of insufficient stability, poor substrate uniformity, expensive raw materials, etc., and achieve reliable morphology control, good crystallinity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Select silicon / silicon dioxide (285nm) as the product substrate, and use acetone, ethanol, and deionized water to perform ultrasonic cleaning for 5 minutes to remove surface impurities, and then dry the surface with dry nitrogen. Use a vacuum plasma cleaner for further surface cleaning, and the cleaning time is 600s.

[0038] 2. Select silicon / silicon dioxide (285nm) as the reactant molybdenum source carrier substrate, the size is 8mm×8mm, use ethanol to ultrasonically clean for 5min, and dry the surface with dry nitrogen.

[0039] 3. Dissolve oxymolybdenum acetylacetonate powder in methanol solution to form a stable sol-gel solution with a concentration of 20 mg / mL. Use a pipette gun to draw 10 mL of oxymolybdenum acetylacetonate solution, drop-coat it on the molybdenum source slide, place the slide on a heating plate at 60°C for 10 seconds, and form a light yellow continuous film on the surface of the slide after annealing. Continue annealing for 5 minutes. After ...

Embodiment 2

[0043] Compared with Example 1, the difference is that 20 mL of molybdenum acetylacetonate solution with a concentration of 10 mg / ml was used for drip coating twice. The carrier gas flow rate was kept constant at 100 sccm during the reaction. When the temperature of the molybdenum source reaction zone reaches 610°C, let the sulfur source reaction furnace start heating, the temperature of the sulfur source reaction zone is set to 160°C, and the temperature of the molybdenum source reaction zone is 750°C.

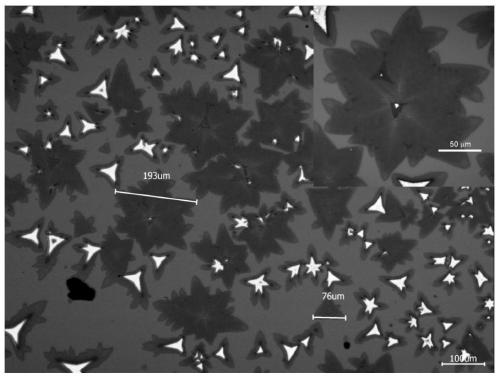

[0044] Figure 5 The topography of the petal-shaped molybdenum disulfide two-dimensional crystal prepared in this example. From Figure 5 It can be seen from the figure that the length and width of the petals of the product are affected by adjusting the carrier gas flow rate. When the air flow is 100 sccm, the petals become longer and narrower.

Embodiment 3

[0046] 1. Select silicon / silicon dioxide (285nm) as the product substrate, and use acetone, ethanol, and deionized water to perform ultrasonic cleaning for 5 minutes to remove surface impurities, and then dry the surface with dry nitrogen. Use a vacuum plasma cleaner for further surface cleaning, and the cleaning time is 600s.

[0047] 2. Select silicon / silicon dioxide (285nm) as the reactant molybdenum source carrier substrate, the size is 5mm×5mm, use ethanol to ultrasonically clean for 5min, and dry the surface with dry nitrogen.

[0048] 3. Dissolve oxymolybdenum acetylacetonate powder in methanol solution to form a stable sol-gel solution with a concentration of 15 mg / mL. Use a pipette gun to absorb 15 mL of oxymolybdenum acetylacetonate solution, drop-coat it on the molybdenum source slide, and form a light yellow continuous film on the surface of the slide after natural air drying. After annealing for 5 minutes, the continuous film on the surface of the slide breaks in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Edge thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com