Lithium ion ternary positive electrode material with high nickel content and low free lithium content, and preparation method and application thereof

A cathode material, lithium-ion technology, applied in the field of preparation of high-nickel ternary cathode materials, can solve the problems of poor safety of lithium-ion batteries, uneven crystal growth, high content of free lithium, etc., and achieve the effect of compatible and flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

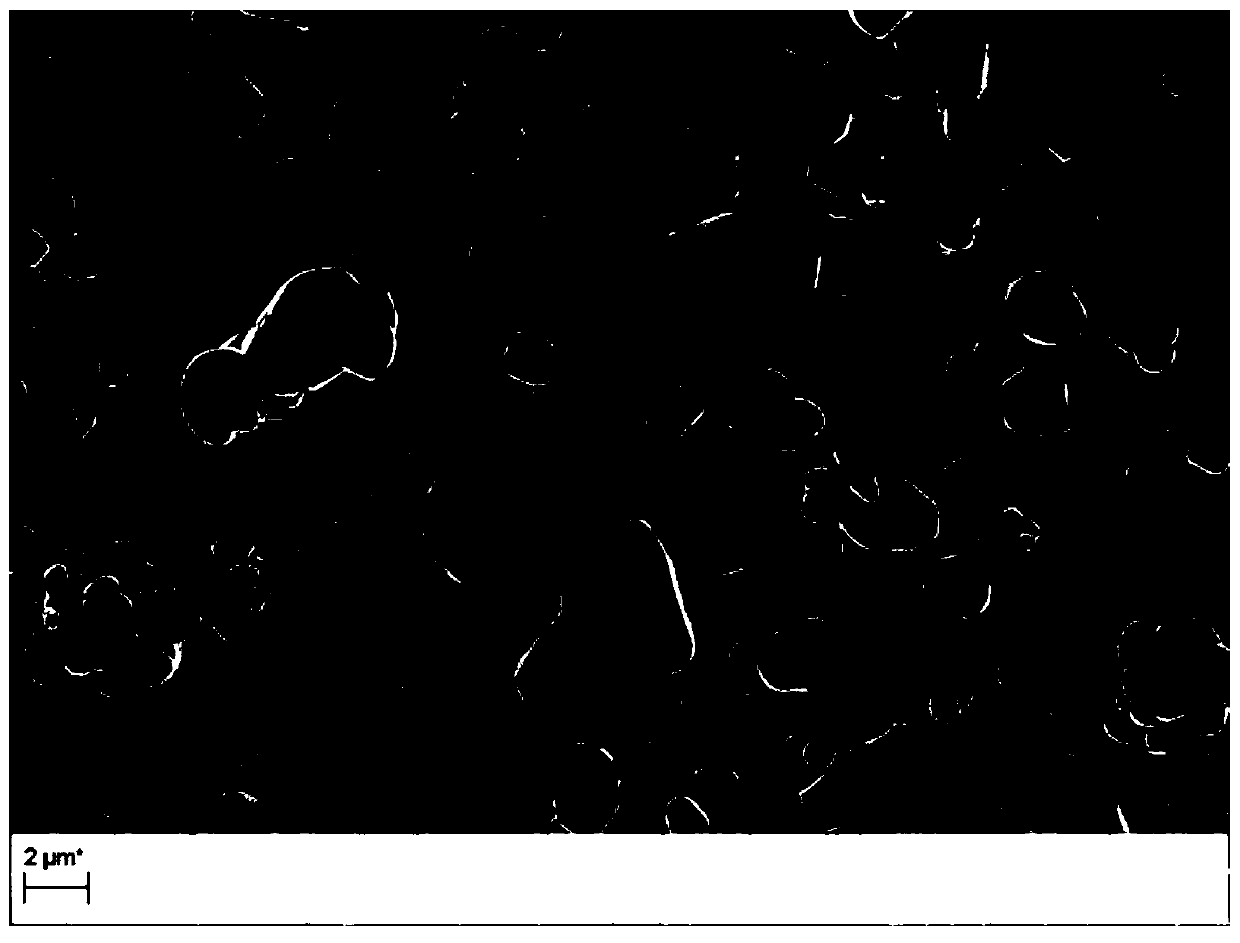

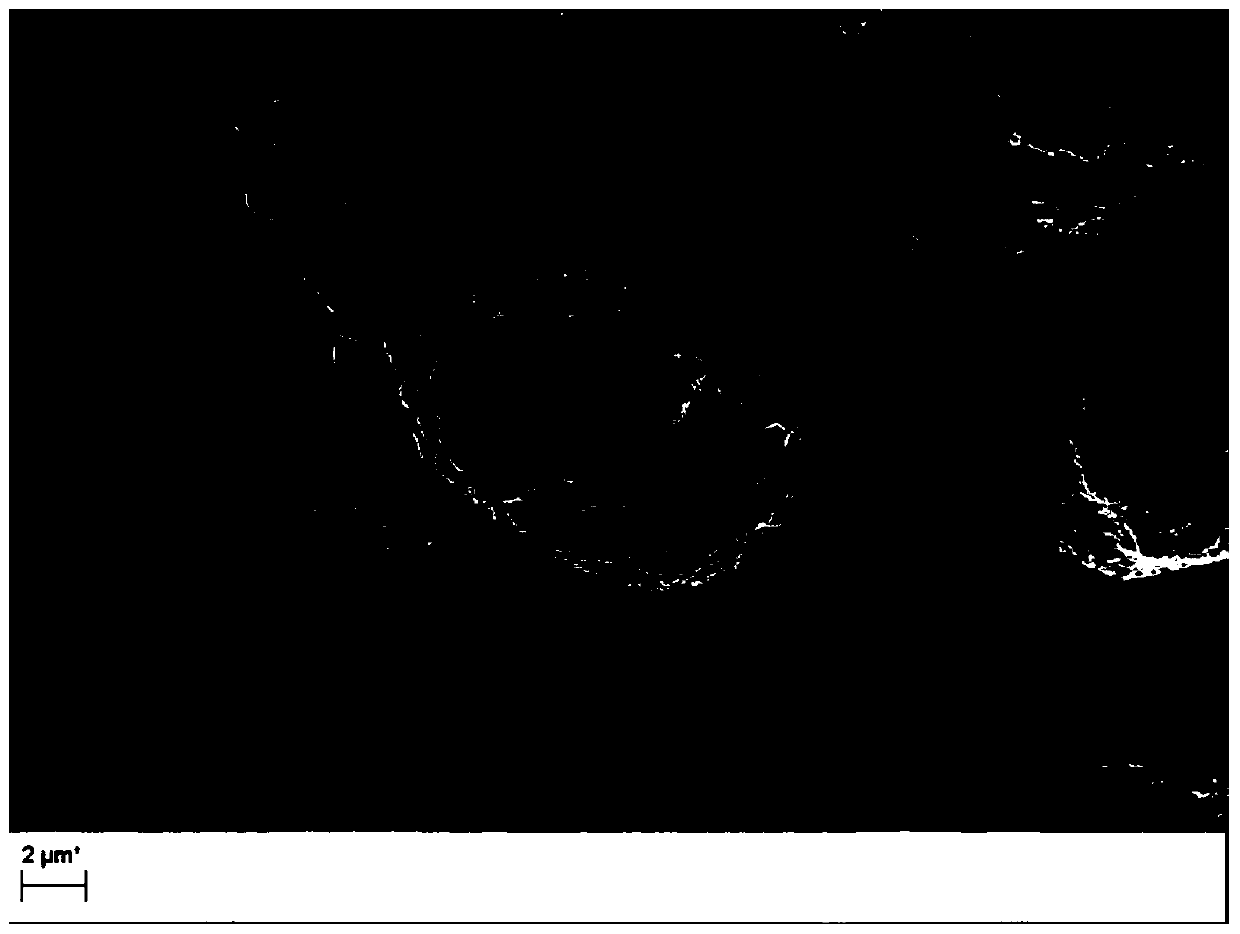

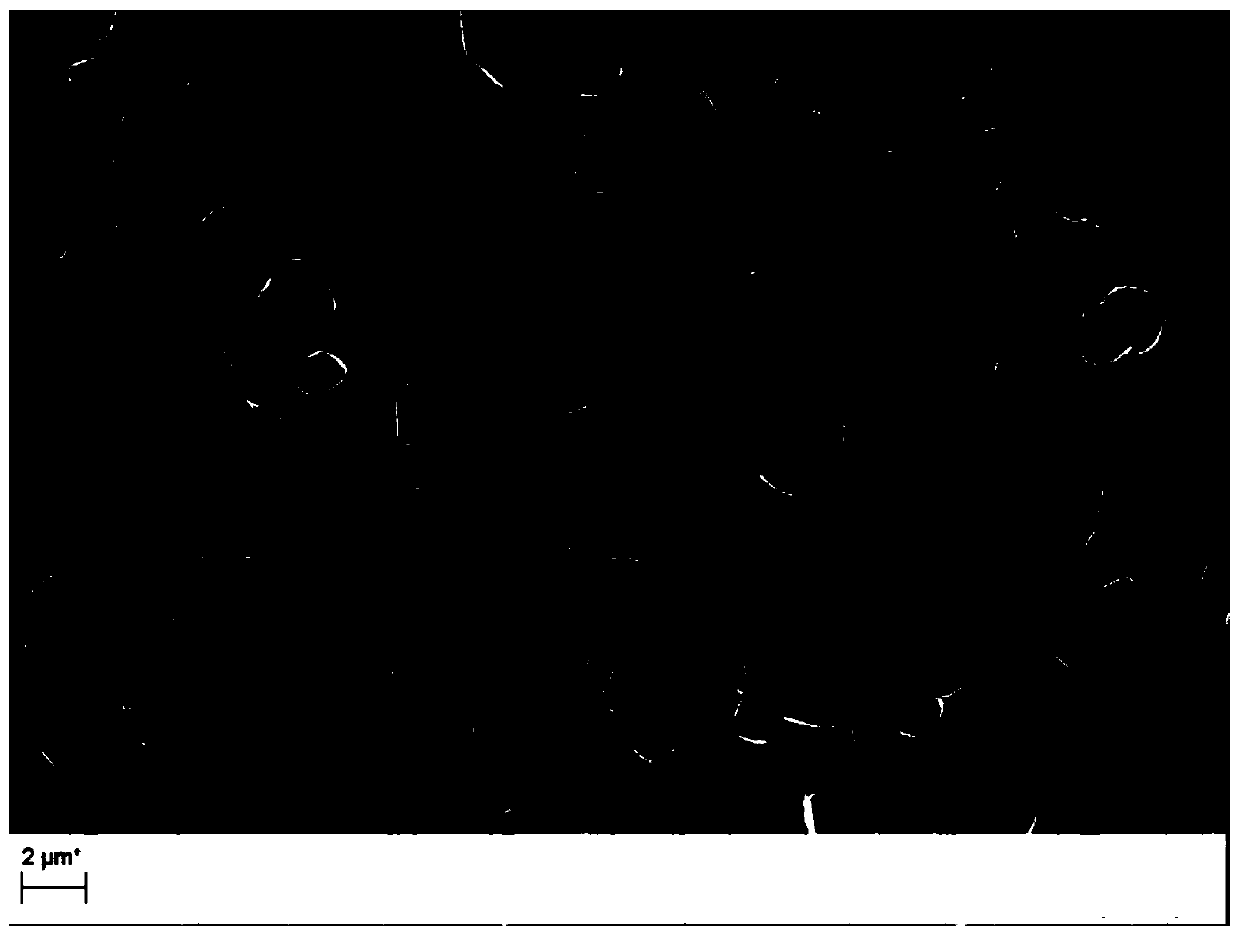

Image

Examples

Embodiment 1

[0098] Take by weighing 27kg monohydrate cobalt carbonate (industrial grade, purity 99wt%), 29.0kg tetrahydrate cobalt acetate (industrial grade, purity 99.0wt%), 115.3kg hexahydrate nickel acetate (industrial grade, purity 99.5%), 17.0kg single Manganese sulfate water, 20.22kg manganese acetate (industrial grade, purity 99.5%) powder, 0.015kg nanometer magnesium oxide (ceramic grade, purity 99.5%), 0.045kg magnesium carbonate (ceramic grade, purity 99.7%) joins in the kneader. Then take the container and slowly add 200.0kg of industrial acetic acid (industrial grade, purity 99.5%, its addition amount is 200% of the mass of the active component of the positive electrode material obtained in theory), and 50kg of deionized water to prepare about 30% acetic acid aqueous solution , and then slowly add the above aqueous acetic acid solution into the kneader under stirring, while controlling the reaction temperature of the solution to be 55°C±5°C. The dropwise addition time is 4 hou...

Embodiment 2

[0105] Take by weighing 19.45kg cobalt carbonate (industrial grade, purity 99wt%), 199.6kg nickel sulfate hexahydrate (industrial grade, purity 99.0wt%), 18.8kg manganese carbonate powder (industrial grade, purity 99.0wt%) joins in the kneader , 0.033kg zirconia (ceramic grade, purity 99.5wt%), slowly add 500.0kg industrial adipic acid (industrial grade, purity 99.5wt%), and its addition is 500% of the mass of the positive electrode material active ingredient that makes in theory ), while controlling the reaction temperature of the solution to be 55°C ± 5°C. Adding time is 4h, add and add 0.92kg zirconium nitrate pentahydrate (industrial grade, 95wt%) again, 0.33kg nano zirconium oxide (ceramic grade, purity 99.5wt%) powder is aged under stirring state for 30 hours, and then use The diaphragm pump is pumped into the high-speed centrifuge for centrifugation, and a pipeline demagnetizer is installed on the pumping pipeline to demagnetize (magnetic field strength 11000GS) until t...

Embodiment 3

[0110] Take by weighing 30.88kg heptahydrate cobalt sulfate (industrial grade, purity 98wt%), 104.6kg nickel carbonate (industrial grade, purity 99.0wt%), 16.7kg manganese sulfate monohydrate (industrial grade, purity 99.5wt%) powder joins kneading in the plane. Take the container again and slowly add 80.0kg industrial isooctanoic acid (industrial grade, purity 99.5%, its addition is 80% of the mass of the positive electrode material active ingredient that is theoretically prepared), and 70kg deionized water, to be mixed with about 83% acetic acid aqueous solution, and then slowly add the above aqueous acetic acid solution into the kneader under stirring, while controlling the reaction temperature of the solution to be 55°C±5°C. Adding time is 4h, add 0.09kg nanometer magnesia (ceramic grade, purity 99.5wt%) powder again after dropping, 1.05kg nanometer zirconia (ceramic grade, purity 99.5wt%), aging 30 under stirring state Hours, then use a diaphragm pump to pump into a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com