MoS2/NiO hollow microsphere material as well as preparation method and application thereof

A hollow microsphere and microsphere technology, applied in chemical instruments and methods, chemical/physical processes, adsorbed water/sewage treatment, etc., can solve the problems of complex preparation process, few active sites, small specific surface area, etc. Simple process, improved catalytic performance, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve 0.32g coconut oil alcohol, 1.4g nickel nitrate hexahydrate, and 0.5403 urea in 225ml deionized water, and stir for 30 minutes to dissolve them all.

[0028] (2) Transfer 40ml of the mixed solution obtained in step (1) to the lining of the hydrothermal reaction kettle, and react at 160°C for 24h.

[0029] (3) Wash the product obtained in step (2) with deionized water and ethanol several times, collect the product, and dry it at 80°C for 24 hours to obtain a precursor.

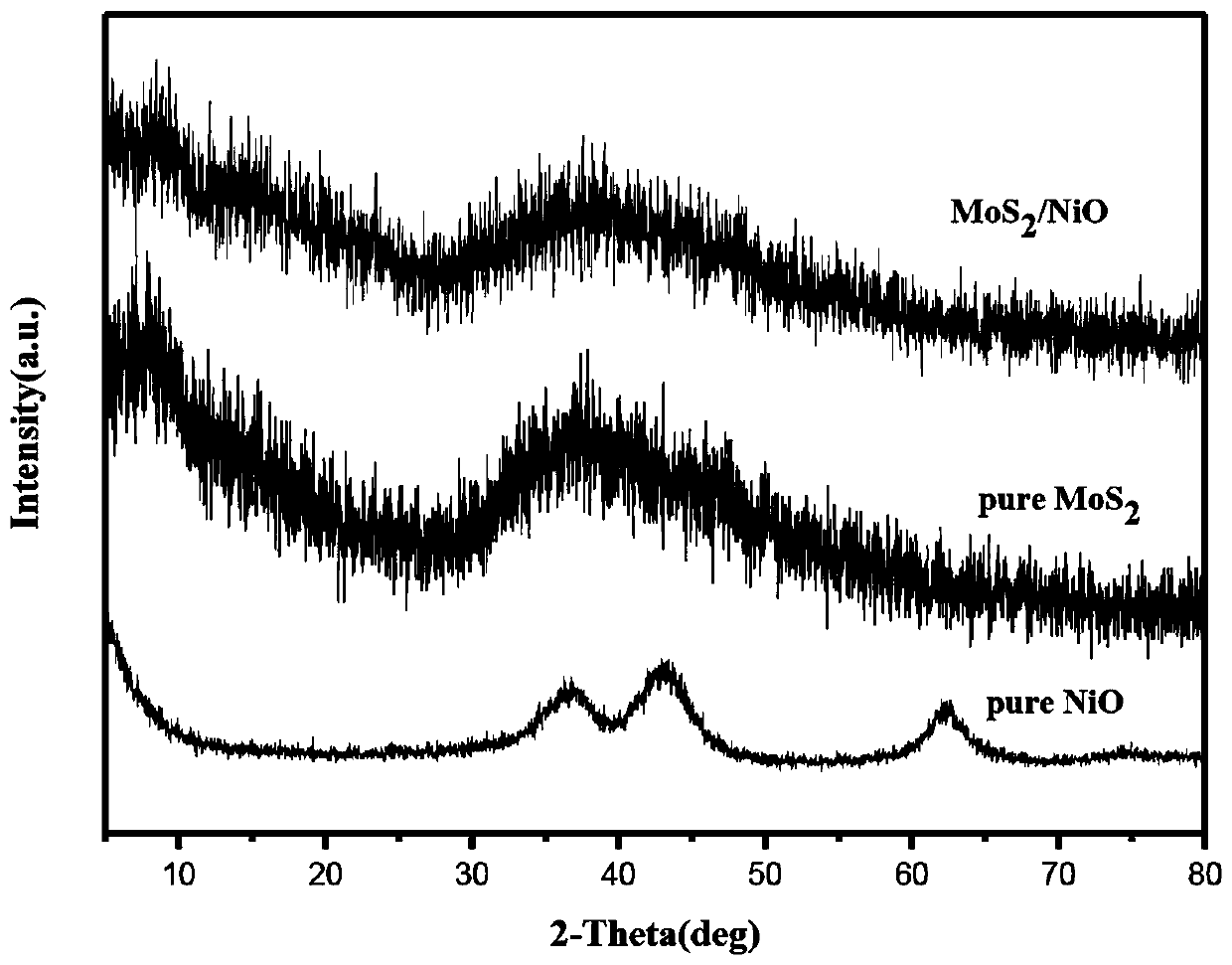

[0030] (4) The precursor obtained in step (3) was sintered at 300 °C for 2 h in an air atmosphere to obtain pure NiO ultrathin nanosheets.

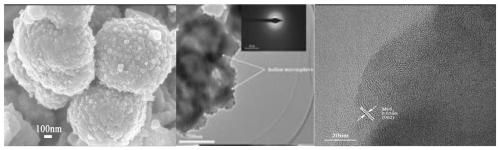

[0031] (5) Dissolve 1mmol ammonium molybdate and 2mmol thiourea in a mixed solution of 30mL ethylenediamine, 8mL ethylene glycol and 2ml, add 0.30g NiO ultra-thin nanosheets, stir at room temperature for 30min, and react the resulting mixed solution at 180°C for 24h. Washing and drying to obtain MoS 2 / NiO hollow microspheres.

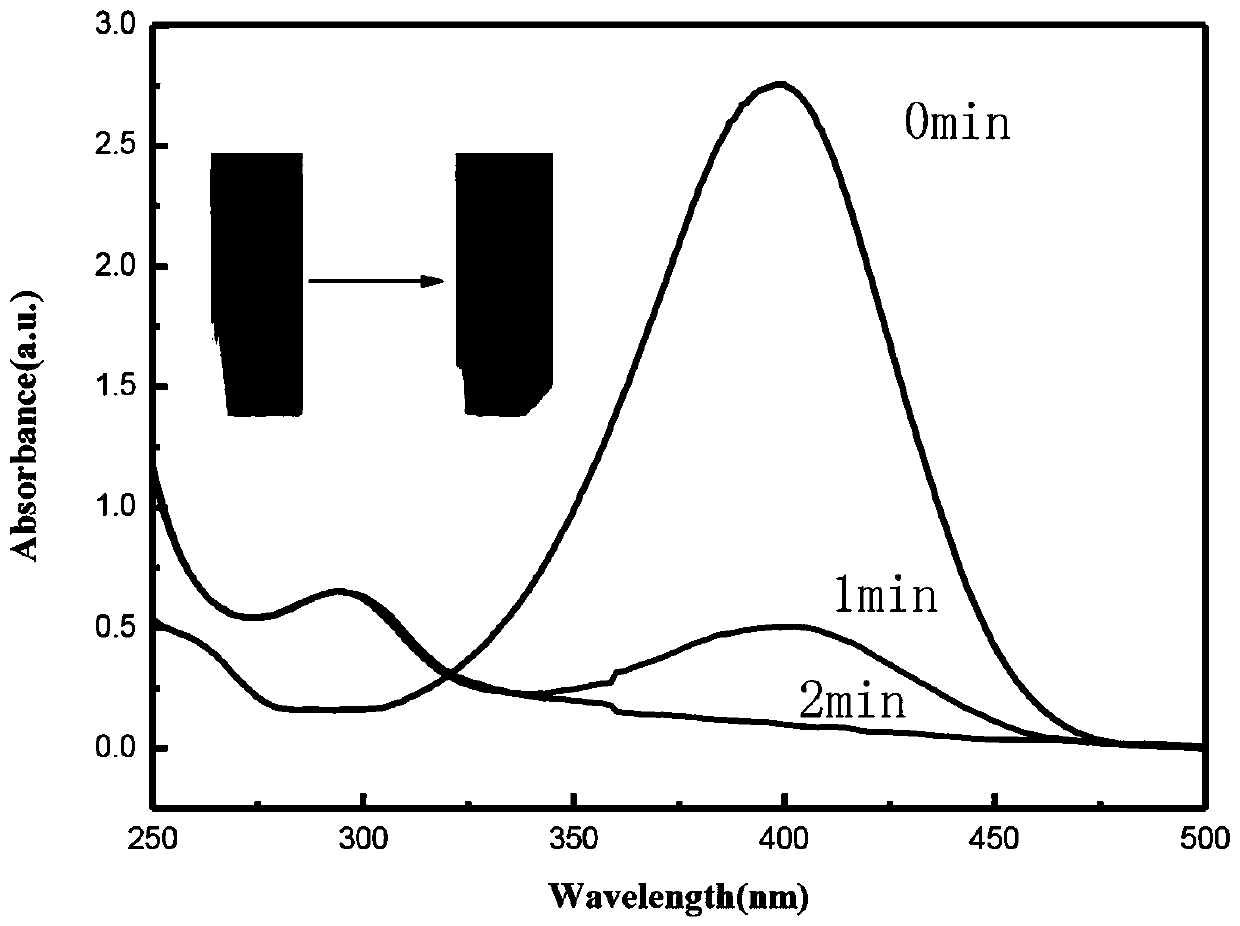

[0032] MoS prepared ab...

Embodiment 2

[0038] (1) Dissolve 0.5g coconut oil alcohol, 2g nickel nitrate hexahydrate, and 0.6 urea in 180ml deionized water, and stir for 30 minutes to dissolve them all.

[0039] (2) Transfer 40ml of the mixed solution obtained in step (1) to the lining of the hydrothermal reaction kettle, and react at 180°C for 24h.

[0040] (3) Wash the product obtained in step (2) with deionized water and ethanol several times, collect the product, and dry it at 80°C for 24 hours to obtain a precursor.

[0041] (4) The precursor obtained in step (3) was sintered at 250°C for 2h in an air atmosphere to obtain pure NiO ultrathin nanosheets.

[0042] (5) Dissolve 1mmol ammonium molybdate and 5mmol thiourea in a mixed solution of 20mL ethylenediamine, 10mL ethylene glycol and 5ml, add 0.04g NiO ultra-thin nanosheets, stir at room temperature for 30min, and react the resulting mixed solution at 180°C for 24h. Washing and drying to obtain MoS 2 / NiO hollow microspheres.

[0043] MoS prepared above 2 ...

Embodiment 3

[0049] (1) Dissolve 0.5g coconut oil alcohol, 2g nickel nitrate hexahydrate, and 0.6 urea in 180ml deionized water, and stir for 30 minutes to dissolve them all.

[0050] (2) Transfer 40ml of the mixed solution obtained in step (1) to the lining of the hydrothermal reaction kettle, and react at 180°C for 24h.

[0051] (3) Wash the product obtained in step (2) with deionized water and ethanol several times, collect the product, and dry it at 80°C for 24 hours to obtain a precursor.

[0052] (4) The precursor obtained in step (3) was sintered at 250°C for 2h in an air atmosphere to obtain pure NiO ultrathin nanosheets.

[0053] (5) Dissolve 1mmol ammonium molybdate and 5mmol thiourea in a mixed solution of 20mL ethylenediamine, 10mL ethylene glycol and 5ml, add 0.08g NiO ultra-thin nanosheets, stir at room temperature for 30min, and react the resulting mixed solution at 180°C for 24h. Washing and drying to obtain MoS 2 / NiO hollow microspheres.

[0054] MoS prepared above 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com