a cr 3+ Activated near-infrared phosphor, preparation method and application

A phosphor and near-infrared technology, applied in chemical instruments and methods, luminescent materials, active medium materials, etc., can solve the problems of untunable luminous efficiency of excitation light, difficulty in growing high-quality single crystals, and high melting point, and achieve energy saving and environmental protection in the preparation process. , Solve the effect of serious thermal effect and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of Na 3 al 0.95 Cr 0.05 MoW 2 o 12

[0030] According to the chemical formula Na 3 al 0.95 Cr 0.05 MoW 2 o 12 The molar ratio of the elements Na, Al, Cr, Mo, W in the 2 CO 3 : 0.795 g, aluminum oxide Al 2 o 3 : 0.242 grams, chromium oxide Cr 2 o 3 : 0.019 g, molybdenum oxide MoO 3 :0.720 g, tungsten oxide WO 3 : 2.319 grams, placed in a mortar and thoroughly ground and mixed uniformly, then calcined the obtained mixture in an air atmosphere, the calcined temperature was 800 ° C, and the calcined time was 1 hour, fully ground and mixed uniformly after being cooled to room temperature, and then in an air atmosphere Calcined again at 900°C, calcination time is 4 hours, cooled and ground to get Cr 3+ Activated near-infrared phosphors.

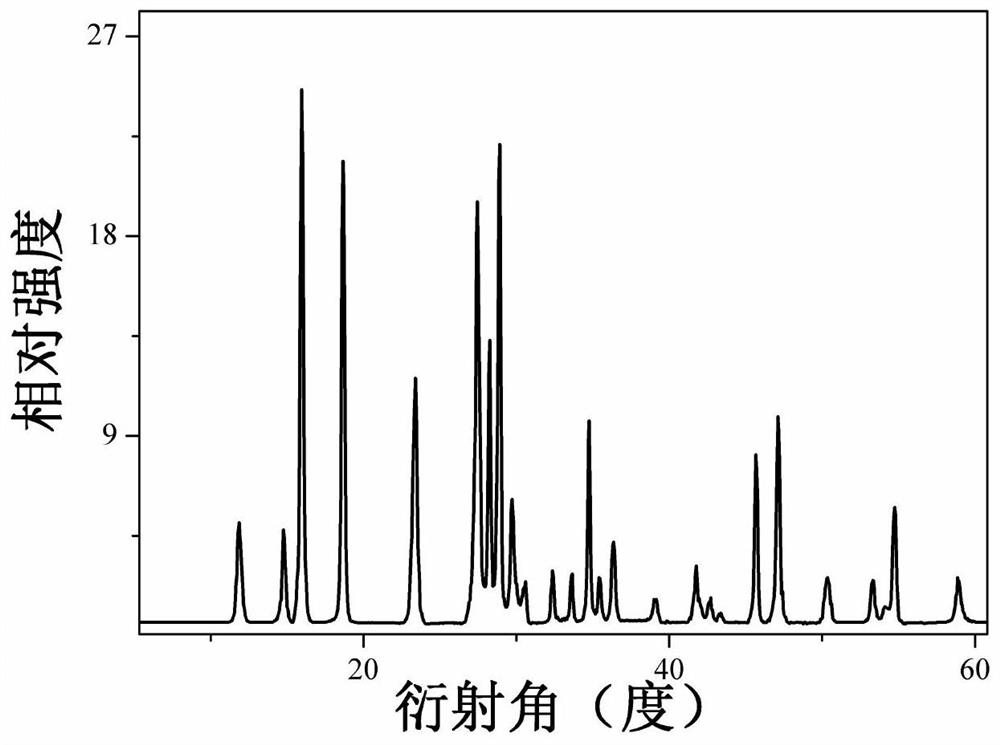

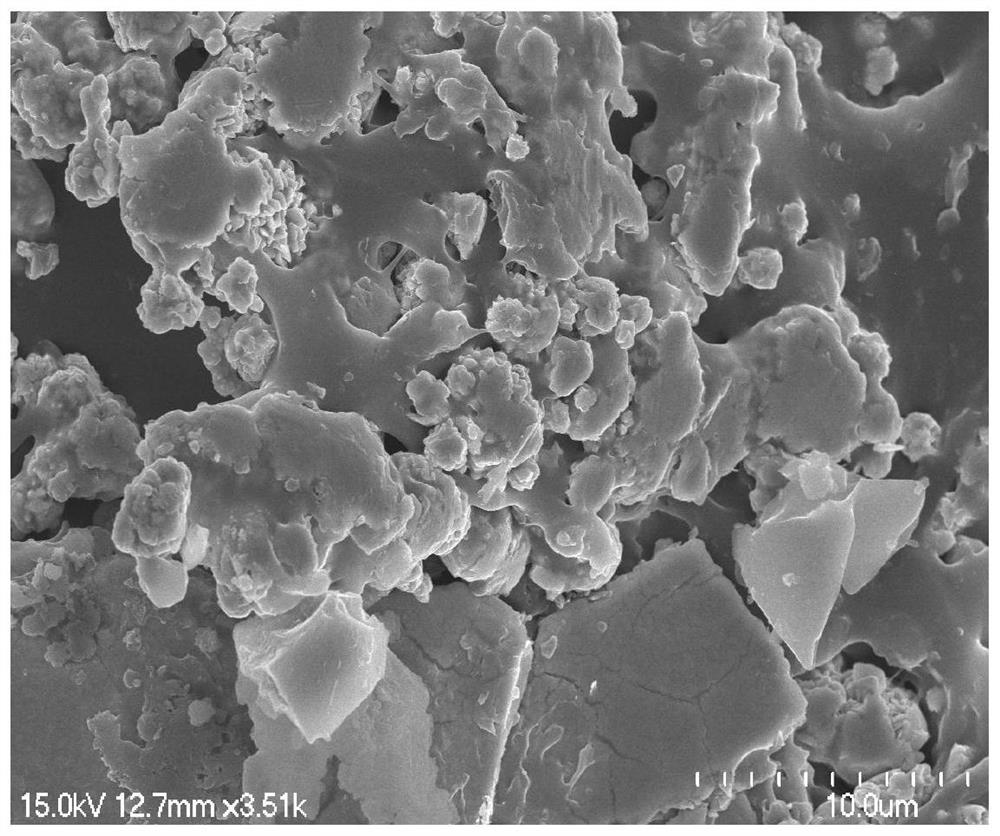

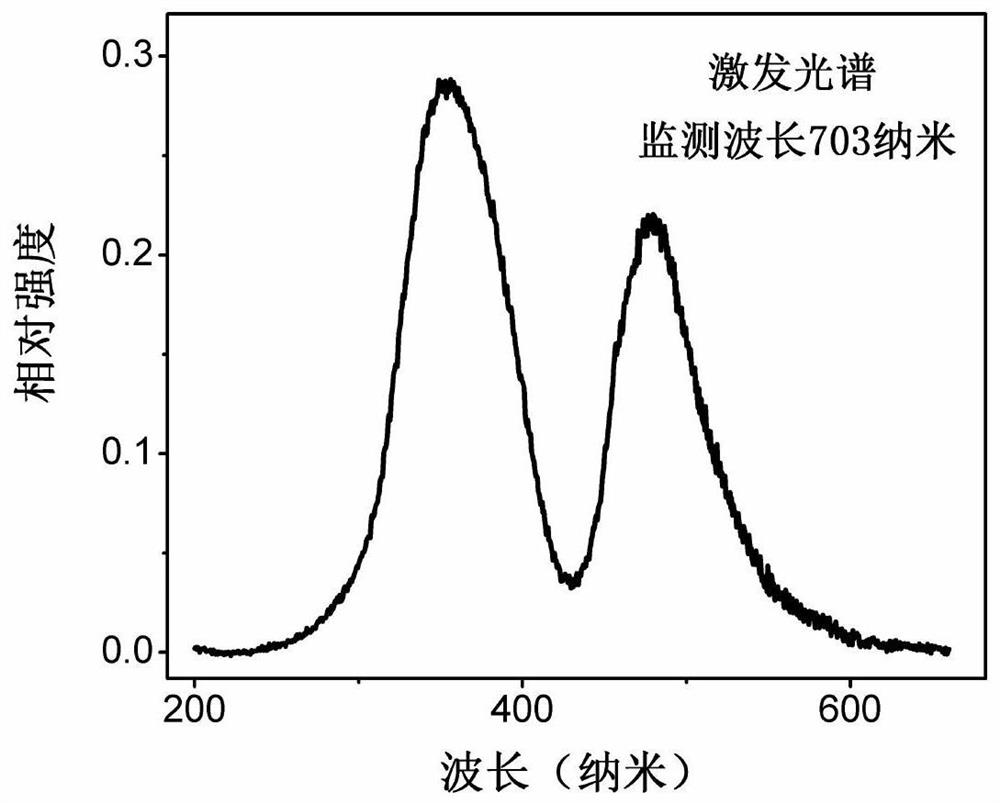

[0031] See attached figure 1 , is the X-ray powder diffraction spectrum of the sample prepared according to the technical scheme of Example 1, which shows that the prepared sample is a single pure phase with hi...

Embodiment 2

[0037] Preparation of Na 3 al 0.999 Cr 0.001 MoW 2 o 12

[0038] According to the chemical formula Na 3 al 0.999 Cr 0.001 MoW 2 o 12 The molar ratio of each element in, weighed sodium bicarbonate NaHCO 3 : 1.260 grams, aluminum hydroxide Al(OH) 3 : 0.390 grams, chromium nitrate Cr (NO 3 ) 3 : 0.001 g, ammonium molybdate (NH 4 ) 2 MoO 4 : 0.980 g and ammonium tungstate (NH 4 ) 10 W 12 o 41 ·xH 2 O: 2.536 grams, placed in a mortar and thoroughly ground and mixed evenly, then calcined under air atmosphere, the calcining temperature is 300°C, and the calcining time is 8 hours, then after cooling down, grind and mix evenly again, and continue calcining under air atmosphere , the calcination temperature is 950°C, and the calcination time is 1 hour. After cooling, take out the sample and grind it into powder to obtain Cr 3+ Activated near-infrared phosphors.

[0039] Cr obtained in this example 3+ The phase, particle morphology, excitation spectrum, emission sp...

Embodiment 3

[0041] Preparation of Na 3 al 0.93 Cr 0.07 MoW 2 o 12

[0042] According to the chemical formula Na 3 al 0.93 Cr 0.07 MoW 2 o 12 The molar ratio of the elements Na, Al, Cr, Mo, W in the element, respectively weighed sodium nitrate NaNO 3 : 1.275 grams, aluminum oxide Al 2 o 3 : 0.237 g, chromium oxide Cr 2 o 3 : 0.027 g, molybdenum oxide MoO 3 : 0.720 g, sodium tungstate dihydrate Na 2 WO 4 2H 2 O: 3.299 grams, placed in a mortar, fully ground and mixed evenly, then pre-calcined the obtained mixture in an air atmosphere, the pre-calcined temperature was 750 ° C, the pre-calcined time was 3 hours, cooled to room temperature, ground and mixed uniformly , calcined again under the air atmosphere, the calcination temperature is 700 ℃, the calcination time is 10 hours, after cooling, grind to get Cr 3+ Activated near-infrared phosphors.

[0043] Cr obtained in this example 3+ The phase, particle morphology, excitation spectrum, emission spectrum and decay curve o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com