Preparation method of nitroolefin derivative with nitrate as nitro source

A technology for nitroalkene and nitrate, which is applied in the field of preparation of nitroalkene derivatives, can solve the problems of low product yield, unfavorable industrial preparation, poor substrate applicability, etc., and achieves cheap and easy-to-obtain raw materials and wide substrates. Applicability, the effect that is beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

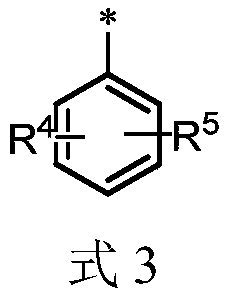

Method used

Image

Examples

Embodiment 1

[0044] React according to the following reaction equation:

[0045]

[0046] Olefins: Target product:

[0047] The specific operation steps are: olefin (100mmol), TMSCl (4 equivalents, 400mmol), guanidine nitrate (2.2 equivalents, 220mmol), copper sulfate pentahydrate (0.1 equivalents, 10mmol), triethylamine (2 equivalents, 200mmol) and acetonitrile (400mL) into a 1000mL Sneaker bottle. First add olefin, copper sulfate pentahydrate, and guanidine nitrate into the Sneck bottle, then add acetonitrile, and finally add TMSCl. The reaction was stirred well at room temperature for 24 hours and monitored by TLC. After the reaction was completed, filter, then add triethylamine to the filtrate, stir for 30 min, wash the mixture with water, and extract 3 times with DCM, then remove the solvent with a rotary evaporator to obtain nitrostyrene.

[0048] Yellow solid: Yield = 92%, 1 H NMR (400MHz, Chloroform-d) δ8.01(d, J=13.7Hz, 1H), 7.59(d, J=13.7Hz, 1H), 7.57-7.53(m, 2H), 7.53...

Embodiment 2-21

[0049] Embodiment 2-21 all reacts by following reaction equation:

[0050]

[0051] The specific operation steps are: olefin (0.5mmol), TMSCl (4 equivalents, 2mmol), guanidine nitrate (2.2 equivalents, 1.1mmol), copper sulfate pentahydrate (0.1 equivalents, 0.05mmol), triethylamine (2 equivalents, 1mmol ) and acetonitrile (3 mL) were added to a 10 mL Snicker tube. First, add olefin, copper sulfate pentahydrate, and guanidine nitrate into the snac tube, then add acetonitrile, and finally add TMSCl. The reaction was stirred well at room temperature for 8-36 hours and monitored by TLC. After the reaction was completed, triethylamine was added, and the mixture was stirred for 25 molecules, and the solvent was removed with a rotary evaporator, and petroleum ether (PE) / ethyl acetate (EA) was used as an eluent, and silica gel (200 mesh sieve) was used. Column chromatography purification.

Embodiment 2

[0053] Olefins: Target product:

[0054] Yellow solid: Yield = 99%, 1 H NMR (400MHz, Chloroform-d) δ8.17 (d, J = 13.7Hz, 1H), 8.03 (d, J = 1.8Hz, 1H), 7.89 (ddd, J = 9.0, 7.2, 3.0Hz, 3H) ,7.71(d,J=13.6Hz,1H),7.65-7.50(m,3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com