Preparation method of sulfide containing sulfur defect and method for photocatalytic reduction of carbon dioxide

A sulfide and defect technology, used in carbon compound catalysts, chemical instruments and methods, and hydrocarbon production from carbon oxides, etc., to achieve high methane selectivity, good reaction stability, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] For visible light catalytic reduction of CO in the prior art 2 The current situation, this application provides a CuIn containing sulfur defects 5 S 8 The preparation method of sulfide, utilize the above-mentioned prepared sulfide to realize CO 2 Catalytic reduction under visible light, and the product has high selectivity and stability. Specifically, the embodiment of the present invention discloses a CuIn containing sulfur defects 5 S 8 The preparation method of sulfide, comprises the following steps:

[0034] Indium chloride tetrahydrate, copper acetate monohydrate and thioacetamide were reacted in an organic solvent to obtain ternary CuIn 5 S 8ultra-thin slices;

[0035] The ternary CuIn 5 S 8 Ultrathin flakes subjected to rapid calcination to obtain CuIn with sulfur defects 5 S 8 sulfide.

[0036] In the preparation of CuIn with sulfur defects 5 S 8 In the process of sulfide, the present application first prepared the complete ternary CuIn 5 S 8 In ...

Embodiment 1

[0053] Add 70mg of indium chloride tetrahydrate and 40mg of copper acetate monohydrate into 30mL of ethylene glycol, stir vigorously for 30min, and when completely dissolved, add 72mg of thioacetamide, stir again for 30min, and transfer the obtained transparent solution to a 40mL high-pressure In the reaction kettle, seal the reaction at 180°C for 24 hours; after the reaction is completed, naturally cool to room temperature, centrifuge the obtained sample, wash with water and ethanol several times, and finally dry the precipitate in a vacuum drying oven; after the sample is dried, take an appropriate amount of the obtained sample In a tube furnace, quickly calcined at 450°C for 2 minutes in a hydrogen-argon (5%) atmosphere, and took it out after cooling to obtain a powder that is ternary CuIn with sulfur defects. 5 S 8 ultra-thin slices.

Embodiment 2

[0056] Add 70mg of indium chloride tetrahydrate and 40mg of copper acetate monohydrate into 30mL of ethylene glycol, stir vigorously for 30min, and when completely dissolved, add 72mg of thioacetamide, stir again for 30min, and transfer the obtained transparent solution to a 40mL high-pressure In the reaction kettle, seal the reaction at 180°C for 24 hours; after the reaction, cool naturally to room temperature, centrifuge the obtained sample, wash with water and ethanol several times, and finally dry the precipitate in a vacuum drying oven to obtain a powder that is the complete ternary CuIn 5 S 8 ultra-thin slices.

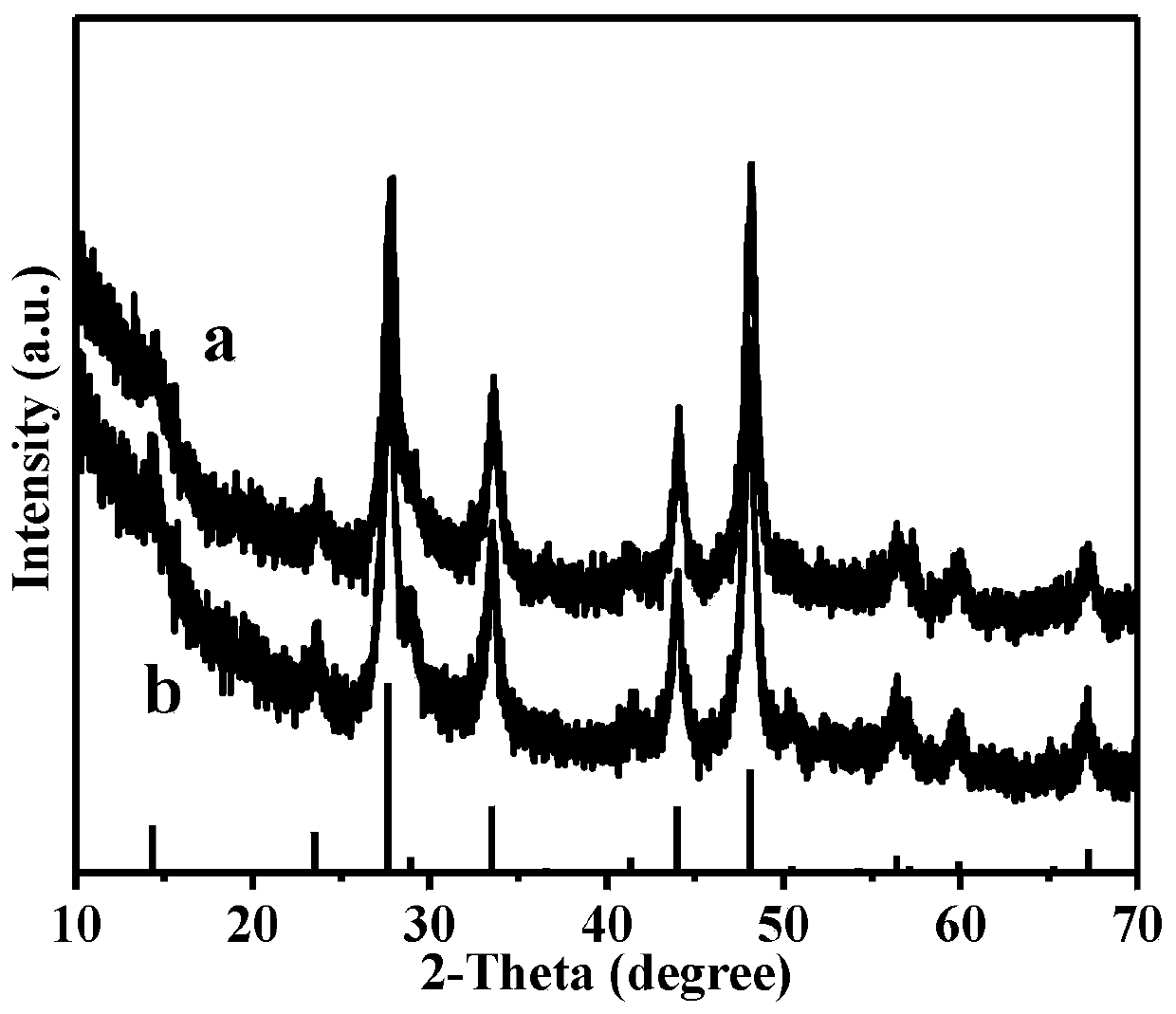

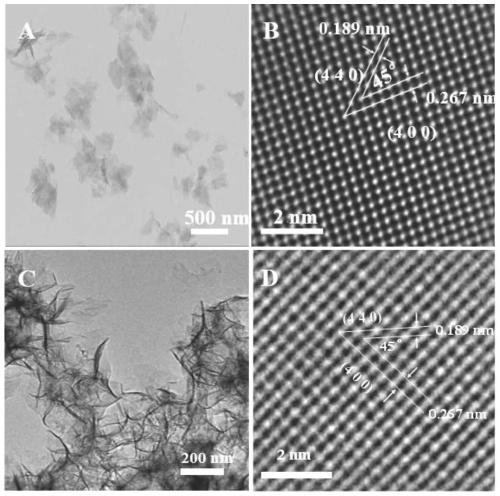

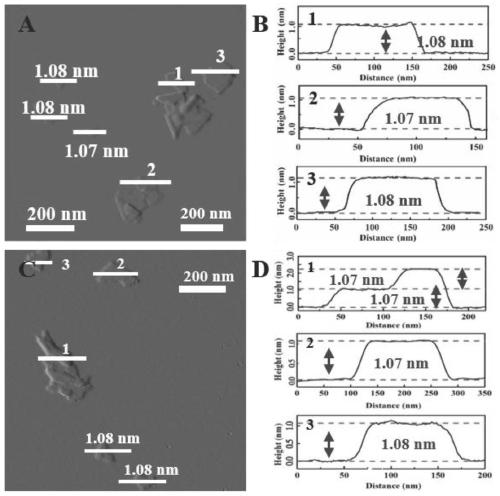

[0057] The compound that embodiment prepares is carried out structural identification, the result sees Figure 1 ~ Figure 3 , figure 1 The complete ternary CuIn prepared in this example is provided 5 S 8 The XRD diffraction pattern of the ultrathin sheet (curve b); figure 2 The complete ternary CuIn prepared in this example is provided 5 S 8 TEM image (F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com