Extractant and preparation method and application thereof

An extraction agent and an unsubstituted technology, applied in the field of extraction agent and its preparation, can solve the problems of difficult solid-liquid separation, large consumption of chemical reagents, and small size of rare earth particles, so as to achieve large rare earth precipitation size, easy solid-liquid separation, The effect of good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention provides the preparation method of above-mentioned extractant, comprises the steps:

[0047] (1) Hydroquinone compound and halogenated alkyl carboxylate react in solvent to obtain crude ester;

[0048] (2) dissolving the crude ester in absolute ethanol and tetrahydrofuran, adding an ethanol solution containing hydroxide to obtain a reaction mixture;

[0049] (3) After removing the solvent of the reaction mixture, the residue was dissolved in water and acidified to obtain an extractant.

[0050]In the above method for preparing the extractant provided by the present invention, firstly, the diphenol compound and the halogenated alkyl carboxylate are mixed in a solvent. Wherein, the alkyl group in the halogenated alkyl carboxylate can be independently selected from substituted straight-chain alkyl groups with 3-12 carbon atoms, unsubstituted straight-chain alkyl groups with 3-12 carbon atoms, substituted branched chain alkyl groups with 3 to 12 carb...

Embodiment 1

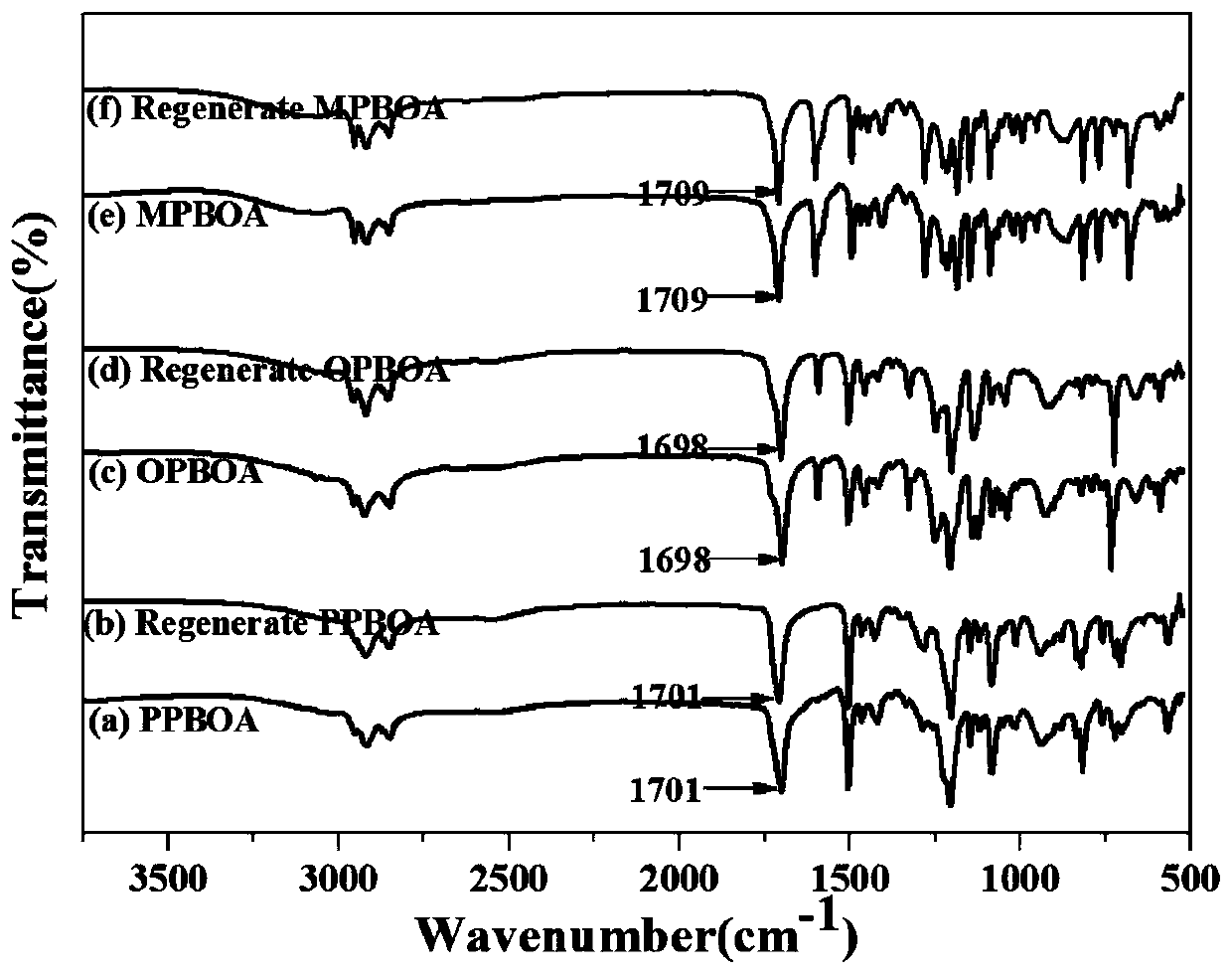

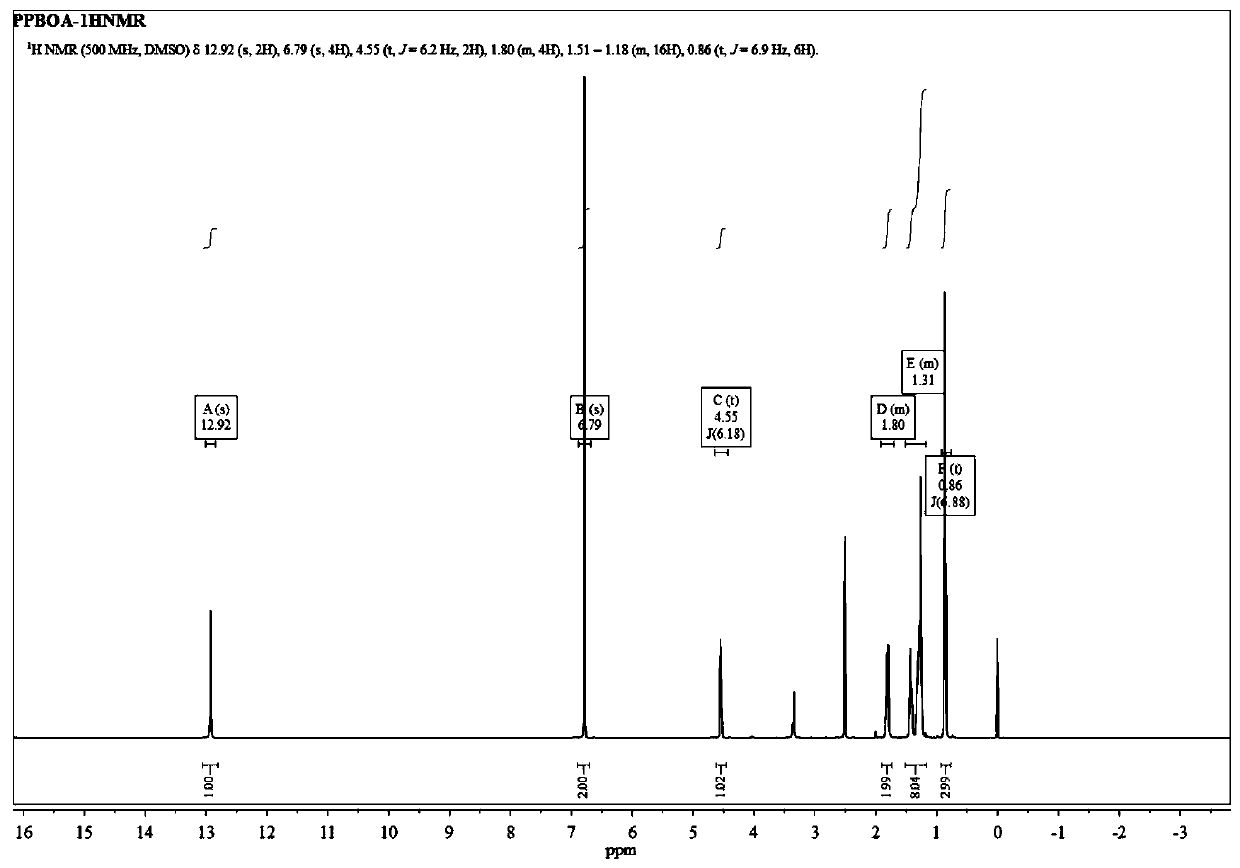

[0070] 1. The preparation method of extractant 2,2'-(1,4-phenylene bis(oxy))dioctanoic acid (PPBOA)

[0071] (1) Add 1.80 g (0.045 mol) of sodium hydride and 20 ml of N,N-dimethylformamide (DMF) into the reaction vessel. Stir at room temperature, and slowly add a solution of hydroquinone (0.02mol, 2.20g of hydroquinone in 20ml of DMF) under argon (or nitrogen) protection to obtain a sodium phenoxide solution; slowly add 2-bromooctanoic acid A solution of methyl ester (0.05mol, 11.9g) was stirred at 60°C for 6 hours; after extraction with cyclohexane, the organic phase was concentrated under reduced pressure to finally obtain the corresponding crude ester.

[0072] Wherein, the reagents selected above can also be replaced by similar reagents to realize the preparation of the extractant, for example: sodium hydride can also be replaced by other alkalis, and N,N-dimethylformamide can also be replaced by N,N-dimethylacetamide ; Methyl 2-bromooctanoate can also be replaced by othe...

Embodiment 2

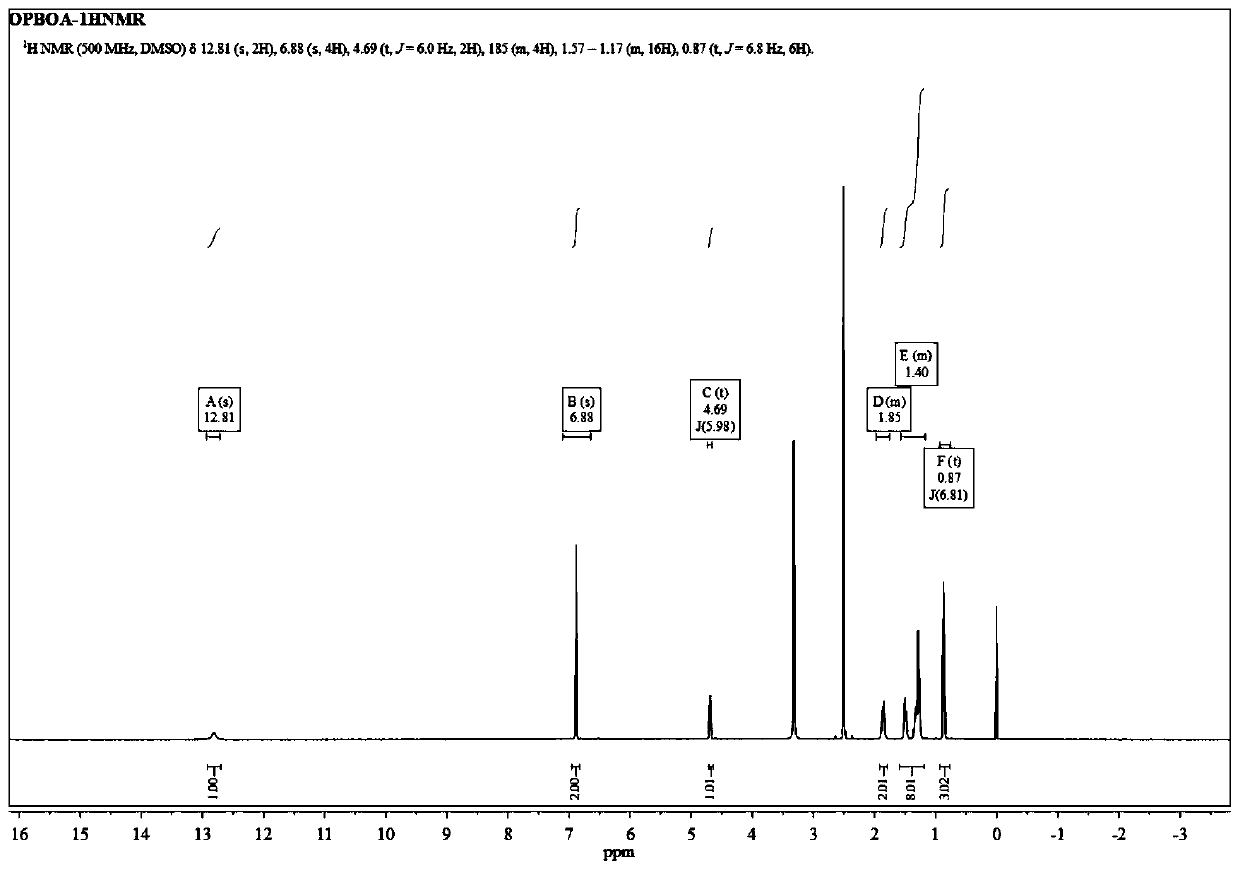

[0085] 1. The preparation method of extractant 2,2'-(1,2-phenylene bis(oxy))dioctanoic acid (OPBOA)

[0086] Add 1.80g (0.045mol) of sodium hydride and 20ml of N,N-dimethylformamide (DMF) into a reaction vessel equipped with a condensation and stirring device, stir at room temperature, and slowly add o-benzene under the protection of argon A solution of diphenol was obtained to obtain a sodium phenoxide solution, a solution of methyl 2-bromooctanoate (0.05mol, 11.9g) was slowly added, and stirred at 75°C for 6 hours; after extraction with cyclohexane, the organic phase was concentrated under reduced pressure, and finally The corresponding crude ester was obtained.

[0087] (2) Dimethyl 2,2'-(1,2-phenylenebis(oxy))dioctanoate, absolute ethanol (C 2 h 5 OH) (60ml) and tetrahydrofuran (THF) (V C2H5OH :V THF , 1:1) was added to the reaction vessel; after complete dissolution, 60ml ethanol solution containing KOH (0.08mol, 4.6448g) was added dropwise at room temperature, and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com