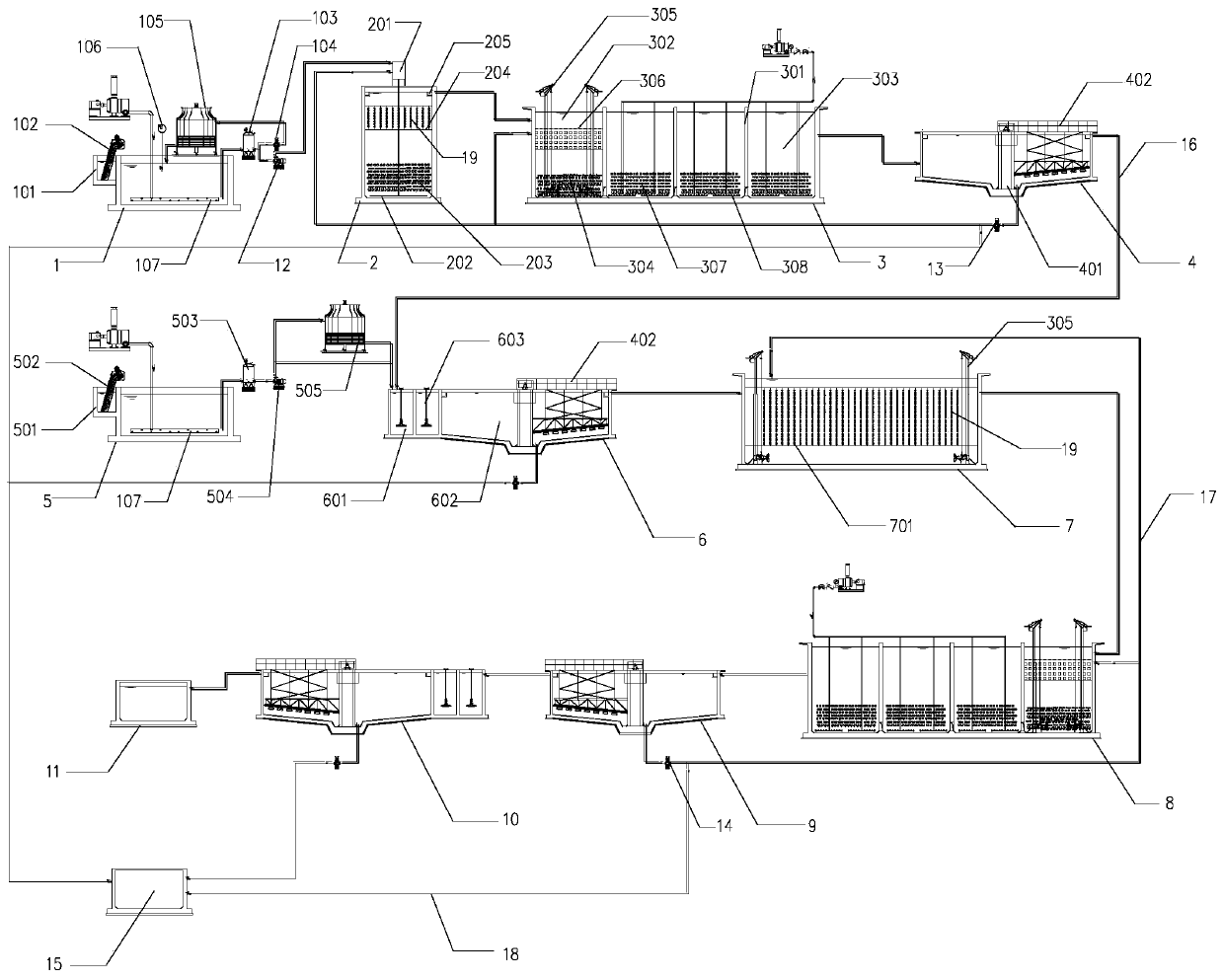

Economical denitrification treatment system for printing and dyeing wastewater

A treatment system, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of wasting operating costs, prolonging treatment time, failing to meet discharge standards, etc., and achieve mud-water mixing effect Improvement, reduction of processing load, effect of good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

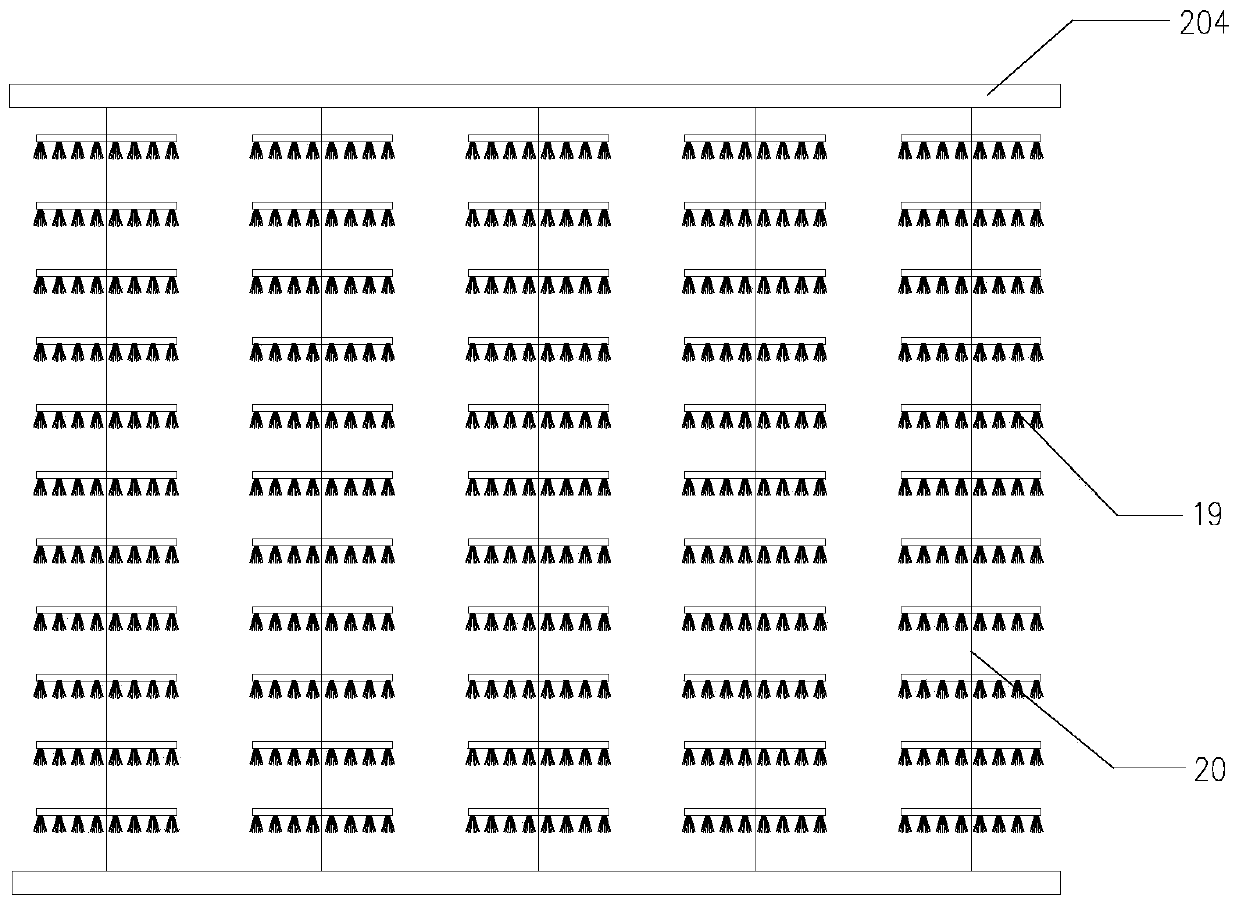

[0076] The pulse anaerobic tank and hydrolytic acidification tank use 235m 3 and 256m 3 The combined filler; the first A / O biochemical pool and the anoxic section of the second A / O biochemical pool each add 200m 3 The modified polyurethane filler, the preparation method of the modified polyurethane filler is:

[0077] Dimensions 30×30×30mm, density 0.04g / cm 3Soak the polyurethane filler in 3% sodium hydroxide solution for 1 hour, then repeatedly wash it with deionized water until the pH of the cleaning solution is 7.2, and dry it at 50°C for 3 hours to obtain a surface-clean polyurethane filler; use the working gas as a volume ratio of 1 :1 O 2 and N 2 The surface-clean polyurethane filler is treated in a low-temperature plasma atmosphere with a treatment power of 600W and a treatment time of 10 minutes; after treatment, the product obtained is immersed in an 8% hydrogen peroxide solution, and the ultraviolet light is turned on, heated to 50°C, and reacted until the soluti...

Embodiment 2

[0079] The pulse anaerobic tank and hydrolytic acidification tank use 235m 3 and 256m 3 The combined filler; the first A / O biochemical pool and the anoxic section of the second A / O biochemical pool each add 200m 3 The modified polyurethane filler, the preparation method of the modified polyurethane filler is:

[0080] Dimensions 15×15×15mm, density 0.03g / cm 3 Soak the polyurethane filler in 5% sodium hydroxide solution for 3 hours, then repeatedly wash it with deionized water until the pH of the cleaning solution is 7.8, and dry it at 70°C for 1 hour to obtain a polyurethane filler with a clean surface; use the working gas as a volume ratio of 1 :3O 2 and N 2 The surface-clean polyurethane filler is treated in a low-temperature plasma atmosphere with a treatment power of 800W and a treatment time of 30min; Stop when the hydrogen oxide concentration is 0.90%; centrifuge the obtained product to dry the surface water stains, wash repeatedly with deionized water, and air-dry ...

Embodiment 3

[0082] The pulse anaerobic tank and hydrolytic acidification tank use 235m 3 and 256m 3 The combined filler; the first A / O biochemical pool and the anoxic section of the second A / O biochemical pool each add 200m 3 The modified polyurethane filler, the preparation method of the modified polyurethane filler is:

[0083] Dimensions 20×20×20mm, density 0.02g / cm 3 The polyurethane filler was soaked in 4% sodium hydroxide solution for 2 hours, then repeatedly washed with deionized water until the pH of the cleaning solution was 7.5, and dried at 60°C for 2 hours to obtain a surface-clean polyurethane filler; the working gas was used as a volume ratio of 1 :2O 2 and N 2 The surface-clean polyurethane filler is treated in a low-temperature plasma atmosphere with a treatment power of 700W and a treatment time of 20min; Stop when the concentration of hydrogen oxide is 0.94%. Centrifuge the obtained product to dry the surface water stains, wash it repeatedly with deionized water, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com