Long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent for rubber and plastic and preparation of long-acting, washable, low-temperature-resistant, colorless and transparent liquid antistatic agent

An antistatic agent and water-resistant technology, which is applied in the field of antistatic agents, can solve the problems that the migration and diffusion ability reduces the conductivity of the system, the migration rate is difficult to obtain antistatic performance, and affects the flexibility and elasticity of rubber, so as to facilitate metering and add dispersion. Handling, excellent washing resistance, effect of enhancing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] A preparation method of a liquid antistatic agent, comprising the following steps:

[0060] 1) Add polyoxyethylene non-ionic surfactant and functional additives to the dispersant to disperse evenly directly or heat to promote dissolution until uniformly dispersed.

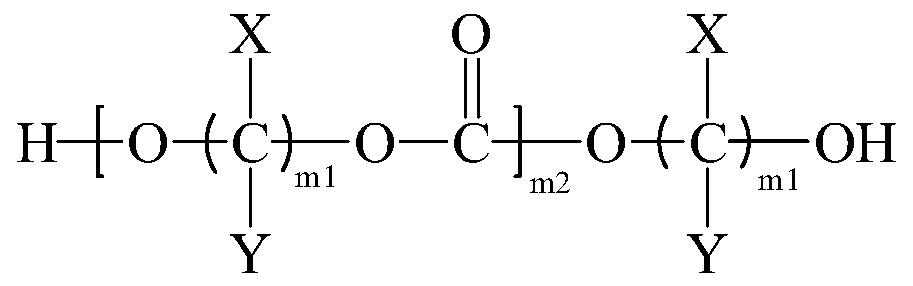

[0061] 2) After the polyester polyol is heated to 30-80°C and melted, it is gradually added to the liquid obtained in step 1).

[0062] 3) Add the ionic compound under stirring condition, and stir until the ionic compound is completely dissolved to obtain the finished product.

Embodiment 1

[0064] A liquid antistatic agent consists of the following components by weight percentage:

[0065] Alkylphenol polyoxyethylene ether (OP-10) 36%,

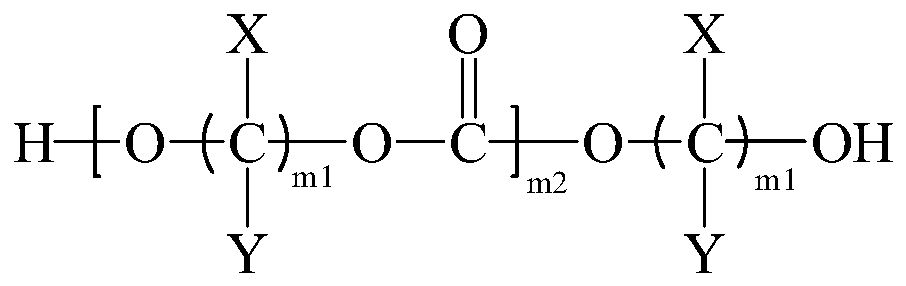

[0066] Polyhexamethylene Adipate Diol 9%,

[0068] Diethyl carbonate and butylene carbonate composite dispersant 38%,

[0069] Dipropylene glycol monobutyl ether adipate 9%.

[0070] Its preparation method comprises the following steps:

[0071] 1) Add OP-10 and dipropylene glycol monobutyl ether adipate to diethyl carbonate and butylene carbonate composite solvent;

[0072] 2) After heating the polyhexamethylene adipate diol to 50°C and completely melting it, gradually add it into the first step system while keeping stirring;

[0073] 3) Add lithium chloride to the system, stir for about 2 hours until the lithium chloride is completely dissolved, the whole system becomes clear and transparent, and the antistatic agent 1 is obtained.

Embodiment 2

[0075] A liquid antistatic agent consists of the following components by weight percentage:

[0076] Nonylphenol ethoxylate 35%,

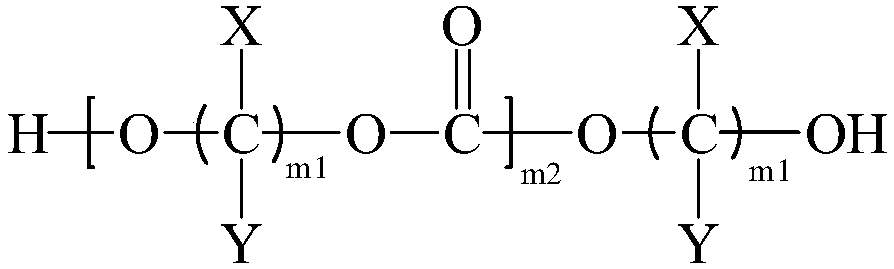

[0077] Poly(1,6-Hexanediol Carbonate) Diol 7%,

[0078] Lithium hexafluorophosphate 10%,

[0079] Methyl propyl carbonate and propylene carbonate composite dispersant 40%,

[0080] Triethylene glycol diisocaprylate 8%.

[0081] Its preparation method comprises the following steps:

[0082] 1) Add nonylphenol polyoxyethylene ether and triethylene glycol diisocaprylate to the composite solvent of methyl propyl carbonate and propylene carbonate;

[0083] 2) After heating poly(1,6-hexanediol carbonate) diol to 60°C and completely melting it, gradually add it into the first step system while keeping stirring;

[0084] 3) Slowly add lithium hexafluorophosphate to the system, and stir for 2-3 hours until the lithium hexafluorophosphate is completely dissolved, and the whole system becomes clear and transparent, and the antistatic agent 2 is obtained....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com