Fabrication method of high-performance aluminum-doped cadmium sulfide silicon-based heterojunction light-emitting diode

A technology of light emitting diodes and cadmium sulfide, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency, low luminous efficiency of energy consumption, and high energy consumption of diodes, so as to improve luminous efficiency and increase carrier migration. rate, the effect of reducing the starting operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation and post-processing of P-type nanoporous silicon columnar arrays

[0041] The process of preparing P-type nanoporous silicon columnar arrays by hydrothermal etching is as follows: (1) Firstly, soak the cut P-type heavily doped single crystal silicon wafer in acetone or ethanol solution for 5 minutes to remove surface organic pollutants , and then deep clean it using the standard RCA cleaning process. (2) Fix the cleaned silicon wafer on the sample holder, put it vertically into the hydrothermal reaction kettle, and inject the prepared corrosion solution (0.03mol / L ferric nitrate nonahydrate, 13mol / L hydrofluoric acid) into the reaction kettle Acid and deionized water composition, reactor filling degree 83%). (3) Put the reactor into a drying oven, raise the temperature to 142°C, keep it warm for 45 minutes, take it out from the drying oven, cool for 60 minutes and open the cover, then cool to room temperature, take out the corroded silicon wafer from th...

Embodiment 1

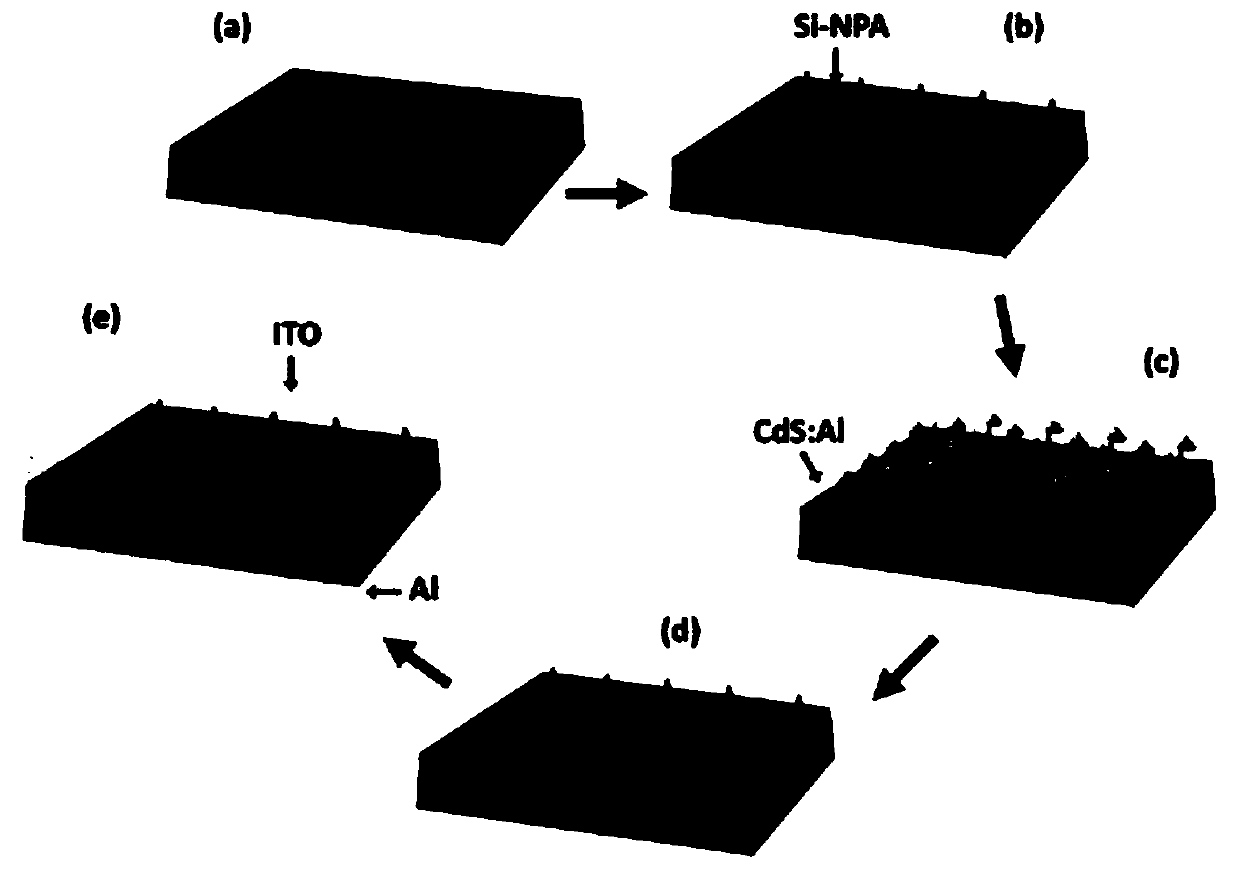

[0049] A method for preparing a high-performance aluminum-doped cadmium sulfide silicon-based heterojunction light-emitting diode, comprising the following steps:

[0050] Step A. Soak the cut P-type heavily doped monocrystalline silicon wafer in acetone or ethanol solution to remove surface organic pollutants, and then perform deep cleaning with standard RCA cleaning process;

[0051] Step B. Fix the cleaned silicon wafer on the sample holder, put it vertically into the hydrothermal reaction kettle, and inject the prepared etching solution into the reaction kettle;

[0052] Step C, putting the reaction kettle into a drying oven, first heating up, and then heat preservation;

[0053] Step D, take it out from the drying oven, cool for 60 minutes and open the cover, then cool to room temperature, take out the corroded silicon wafer from the reaction kettle, rinse it repeatedly with deionized water, and dry it naturally to obtain the nanoporous silicon columnar array;

[0054] S...

Embodiment 2

[0062] A method for preparing a high-performance aluminum-doped cadmium sulfide silicon-based heterojunction light-emitting diode, comprising the following steps:

[0063] Step A. Soak the cut P-type heavily doped monocrystalline silicon wafer in acetone or ethanol solution to remove surface organic pollutants, and then perform deep cleaning with standard RCA cleaning process;

[0064] Step B. Fix the cleaned silicon wafer on the sample holder, put it vertically into the hydrothermal reaction kettle, and inject the prepared etching solution into the reaction kettle;

[0065] Step C, putting the reaction kettle into a drying oven, first heating up, and then heat preservation;

[0066] Step D, take it out from the drying oven, cool for 60 minutes and open the cover, then cool to room temperature, take out the corroded silicon wafer from the reaction kettle, rinse it repeatedly with deionized water, and dry it naturally to obtain the nanoporous silicon columnar array;

[0067] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com