A photoelectric integrated thin film power supply system and its preparation and application

A power system and thin-film battery technology, applied in the field of batteries, can solve the problems of reduced portability and safety, lower battery energy conversion efficiency, and no consideration of thin-film integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

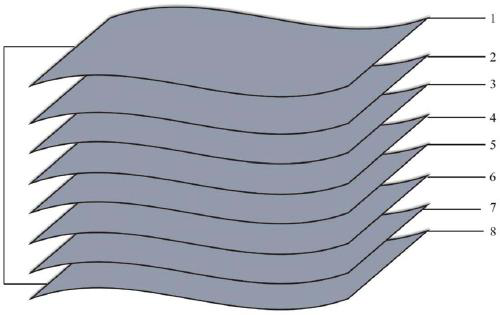

[0094] The invention provides a photoelectric integrated thin film power supply system, its structure includes a lithium ion battery part and a solar battery part, the specific structure is as follows figure 1 As shown, 5-Mo foil is used as the film substrate, 4-CZTS is sputtered on one side by magnetron sputtering, 6-CZTS is sputtered on the other side of the 5-Mo foil by magnetron sputtering, annealed Afterwards, continue to use the film as the substrate, continue to sputter the electrolyte 3-LiPON on the 4-CZTS side, and the positive electrode material 2-LiCoO 2 , the current collector 1-Al is used as the part of the lithium-ion battery, the buffer layer 7-CdS is sputtered on the 6-CZTS side, and the window layer 8-IZO / ITO is used as the solar cell part, where the 8-window layer is connected to the 1-current collector , this type of connection will not connect other layers. The battery system is packaged with silicone resin adhesive, and the two stages of 1-Al and 5-Mo foi...

Embodiment 2

[0097] The invention provides an optoelectronic integrated film power system, the structure of which includes a lithium ion battery part and a solar battery part, wherein 5-Mo foil is used as a film substrate, and 4-CZTS is respectively sputtered by magnetron sputtering on one side, and The other side of the 5-Mo foil was sputtered with 6-CZTS by magnetron sputtering. After annealing, the film continued to be used as the substrate, and the electrolyte 3-LiPON was sputtered on the 4-CZTS side, and the positive electrode material 2-LiNi 0.8 mn 0.1 co 0.1 o 2 , the current collector 1-Al is used as the part of the lithium-ion battery, the buffer layer 7-CdS is sputtered on the 6-CZTS side, and the window layer 8-IZO / ITO is used as the solar cell part, where the 8-window layer is connected to the 1-current collector , this type of connection will not connect other layers. The battery system is packaged with silicone resin adhesive, and the two stages of 1-Al and 5-Mo foil are u...

Embodiment 3

[0100] The invention provides an optoelectronic integrated thin-film power supply system, the structure of which includes a lithium ion battery part and a solar battery part, wherein 6-Mo foil is used as a thin film substrate, and magnetron sputtering is used to sputter 5-Cu, 4 -CZTS sputtered 7-CZTS on the other side of the 6-Mo foil by magnetron sputtering. After annealing, the film continued to be used as the substrate, and the electrolyte 3-LiPON was continued to be sputtered on the 4-CZTS side, and the positive electrode material 2- LiNi 0.5 mn 0.3 co 0.2 o 2 , the current collector 1-Al is used as the part of the lithium-ion battery, the buffer layer 7-CdS is sputtered on the 6-CZTS side, and the window layer 8-IZO / ITO is used as the solar cell part, where the 8-window layer is connected to the 1-current collector , this type of connection will not connect other layers. The battery system is packaged with silicone resin adhesive, and the two stages of 1-Al and 5-Mo f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com