Preparation method and application of porous silicon sphere supported H3PW6Mo6O40 catalyst

A multi-level porous, heteropolyacid technology, applied in catalyst activation/preparation, organic compound preparation, chemical instruments and methods, etc. and other problems, to achieve the effect of improving product selectivity, increasing pore volume, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

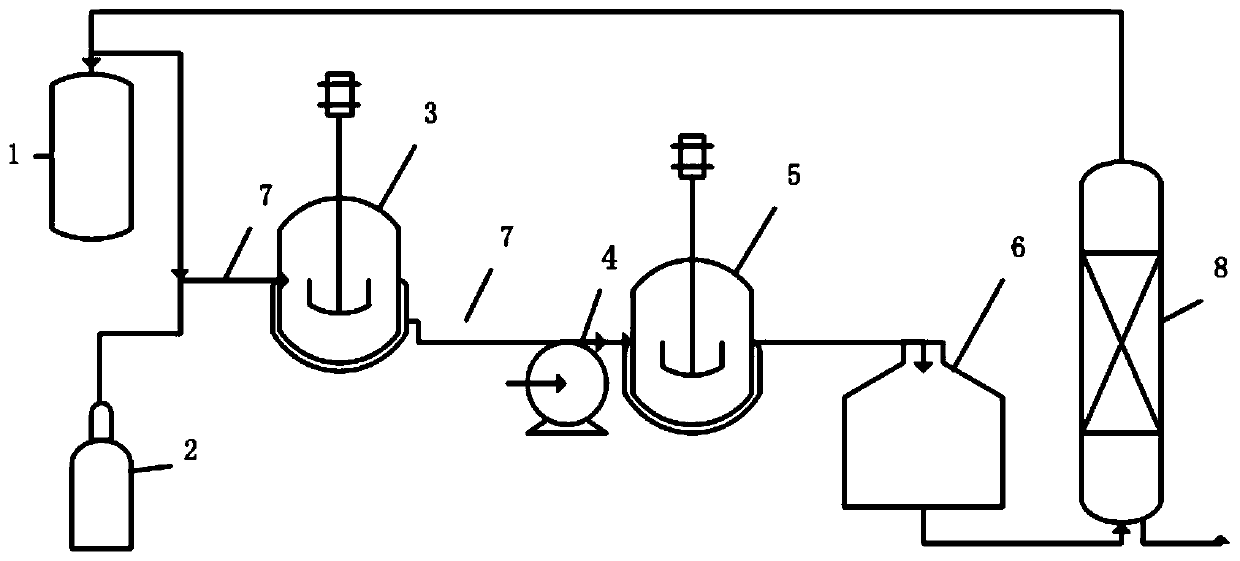

Method used

Image

Examples

Embodiment 1

[0038] With 1-ethyl-3-methylimidazolium bromide, tetramethylammonium chloride, ethyl orthosilicate, polyhexadiene dimethyl ammonium chloride, tetraethylammonium hydroxide according to mass ratio 18: 6:1:1:2 Synthesis of Hierarchical Porous Silicon Spheres: Stir 90g of 1-ethyl-3-methylimidazolium sodium bromide at 80°C, and then add 30g of tetramethylammonium chloride dropwise to it , then add 5g of polyhexadiene dimethyl ammonium chloride and 5g of tetraethylammonium hydroxide to the above system, after stirring for 1h, slowly add 10g of tetraethyl orthosilicate into the mixed solution, and continue to stir 4h, put the obtained white emulsion into a high-pressure hydrothermal kettle for crystallization at 180°C for 24h, the crystallized product was centrifuged, washed, and dried at 60°C for 6h to obtain a white solid powder, and then placed in a muffle furnace at 550°C Calcined at high temperature for 6h to obtain hierarchical porous silicon spheres.

[0039] 3g phosphomolybd...

Embodiment 2

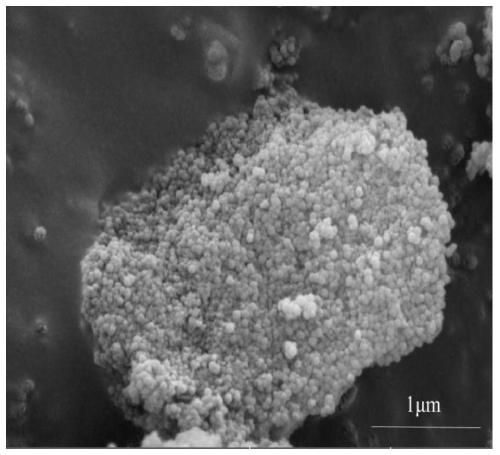

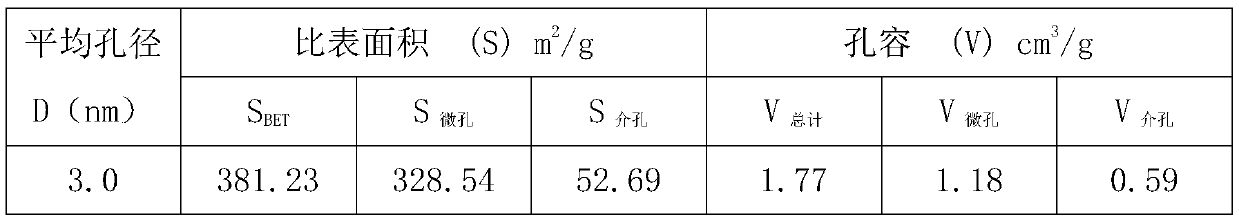

[0045] With 1-ethyl-3-methylimidazolium bromide, tetramethylammonium chloride, ethyl orthosilicate, polyhexadiene dimethylammonium chloride, tetraethylammonium hydroxide according to mass ratio 19: 8:2:2:3 Synthesis of hierarchically porous silicon spheres: Stir 95g of 1-ethyl-3-methylimidazolium sodium bromide at 70°C, and then add 40g of tetramethylammonium chloride dropwise to it , then add 10g of polyhexadiene dimethyl ammonium chloride and 10g of tetraethylammonium hydroxide to the above system, after stirring for 1.5h, slowly add 15g of tetraethyl orthosilicate into the mixed solution, continue Stir for 3 hours, put the obtained white emulsion into a high-pressure hydrothermal kettle for crystallization at 200°C for 18 hours, centrifuge, wash, and dry at 70°C for 5 hours to obtain a white solid powder after drying, and then place it in a muffle furnace Calcined at 540°C for 2 hours to obtain hierarchical porous silicon spheres, the electron micrographs of which are shown...

Embodiment 3

[0051] With 1-ethyl-3-methylimidazolium bromide, tetramethylammonium chloride, ethyl orthosilicate, polyhexadiene dimethyl ammonium chloride, tetraethylammonium hydroxide according to mass ratio 20: 9:3:3:4 Synthesis of Hierarchical Porous Silicon Spheres: Stir 100g of 1-ethyl-3-methylimidazolium sodium bromide at 100°C, and then add 45g of tetramethylammonium chloride dropwise to it , then add 15g of polyhexadiene dimethyl ammonium chloride and 15g of tetraethylammonium hydroxide to the above system, after stirring for 2h, slowly add 20g of tetraethyl orthosilicate into the mixed solution, and continue to stir 2h, the obtained white emulsion was put into a high-pressure hydrothermal kettle for crystallization at 120°C for 12h, the crystallized product was centrifuged, washed, and dried at 80°C for 4h to obtain a white solid powder, and then placed in a muffle furnace at a temperature of 450°C Calcined for 10 hours to obtain hierarchical porous silicon spheres.

[0052] 9g ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com