A kind of acidic ionic liquid@cof material and its preparation method and application

An acidic ionic liquid, ionic liquid technology, applied in chemical instruments and methods, catalytic reactions, physical/chemical process catalysts, etc., can solve the problems of difficult catalyst separation and recovery, complex pore structure, complicated experimental operation, etc., and achieve easy recovery. Separation, high catalytic efficiency, overcoming the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0056] Implementation method: Add 28.1g TAPB and 23.3g DMTA into a pressure-resistant tube (10mL, length 20cm, neck length 15cm), add 10mg 1-methyl-3-sulfopropylimidazolium bisulfate ionic liquid ([MSPI] [HSO 4 ]) (dissolved in 0.1mL water), 1mL mixed solvent (1,2-dichlorobenzene / n-butanol=1 / 1, v / v), sonication for 5min, freezing the solvent with liquid nitrogen, connecting a vacuum pump, the pressure in the tube When the temperature is lowered to 20Pa, seal the tube with a flame vacuum, wait until it returns to room temperature, put it in an oven, and react at 120°C for 3 days. After the reaction, cool to room temperature, break the pressure bottle, centrifuge to obtain a solid, wash with THF (3×10mL) and methanol (3×10mL), extract with THF for 1 day, and dry under vacuum at 120°C for 12h Catalyst B is obtained.

Embodiment 3

[0058] Implementation method: with embodiment 2, add 30mg ionic liquid [MSPI] [HSO 4 ] (dissolved in 0.1mL water), other constant, obtain catalyst C.

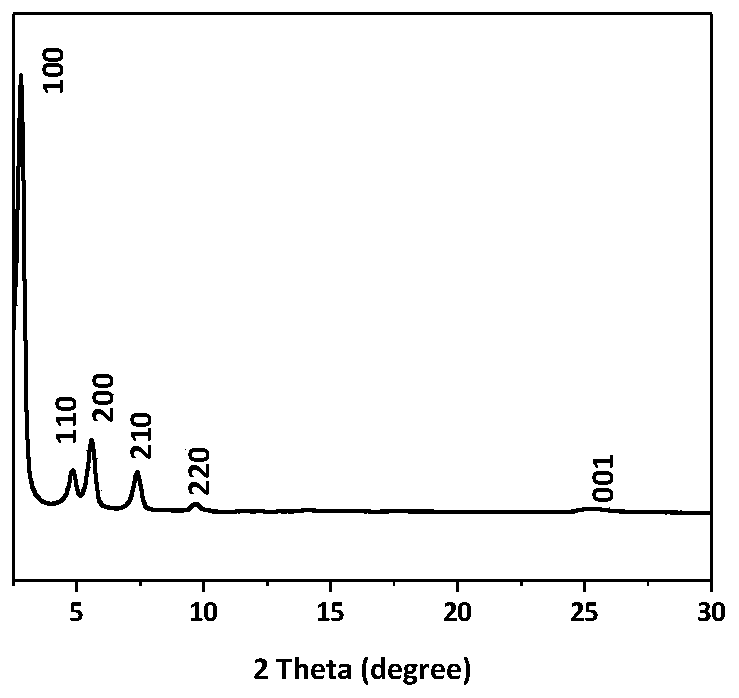

[0059] The prepared acidic ionic liquid @COF material was characterized by XRD, as shown in figure 1 shown. Depend on figure 1 The test results shown show that it is a highly crystalline porous material.

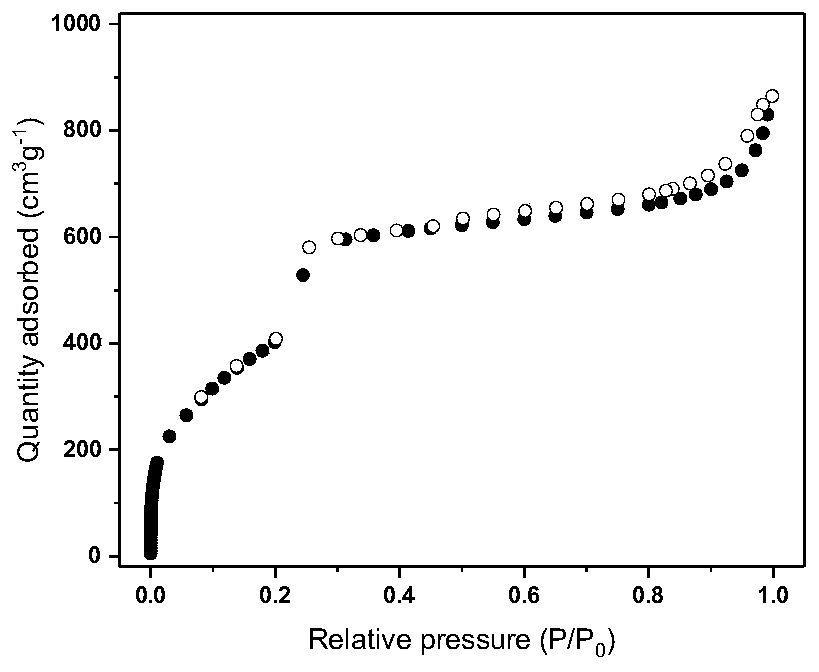

[0060] The prepared acidic ionic liquid @COF material was subjected to nitrogen adsorption and desorption tests, and the following results were obtained: figure 2 as shown. Depend on figure 2 The test results shown show that the catalyst has a micro- and mesoporous structure, which further demonstrates that it has a rich pore structure and a large specific surface area.

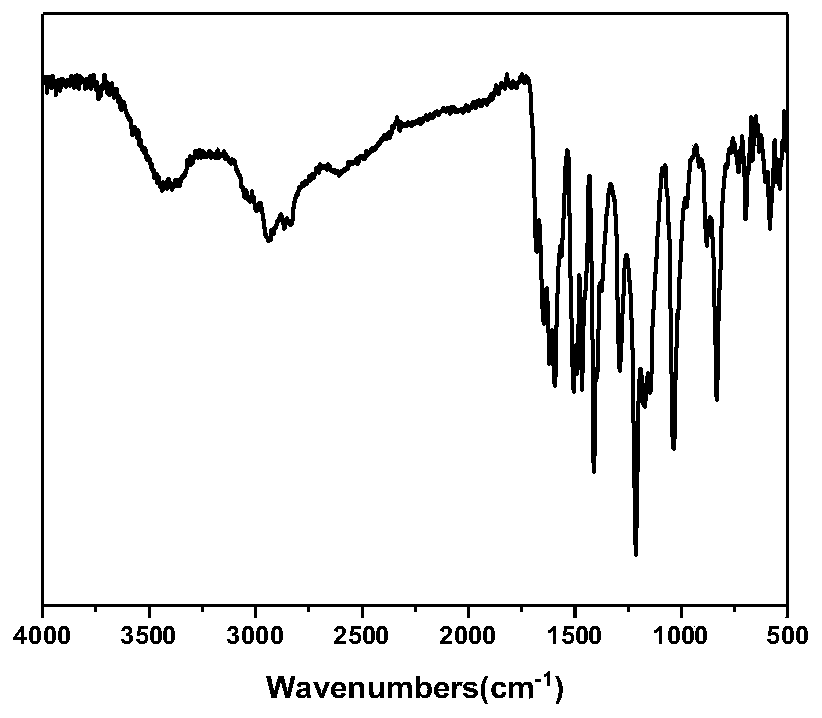

[0061] The prepared acidic ionic liquid @COF material was tested by infrared spectroscopy, and the results were as follows image 3 shown. Depend on image 3 The test results shown show that the catalyst was successfully synthesized and the acidic...

Embodiment 4

[0064] Implementation method: with embodiment 2, add 50mg ionic liquid [MSPI] [HSO 4 ] (dissolved in 0.1mL water), other constant, obtain catalyst D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com