Filter mud high-temperature composting inoculant LC and its application

A technology of high-temperature composting and filtering mud, which is applied in the field of recycling of agricultural and forestry wastes, can solve the problems of limiting the high-temperature composting of filter mud to decompose and stabilize, microorganisms are difficult to enter and decompose, and bacterial strains lose their activity, so as to achieve sustainable development, promote recycling, The effect of promoting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

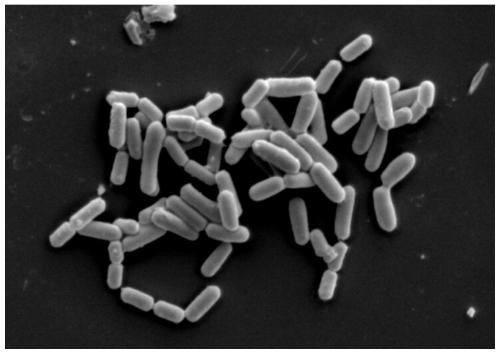

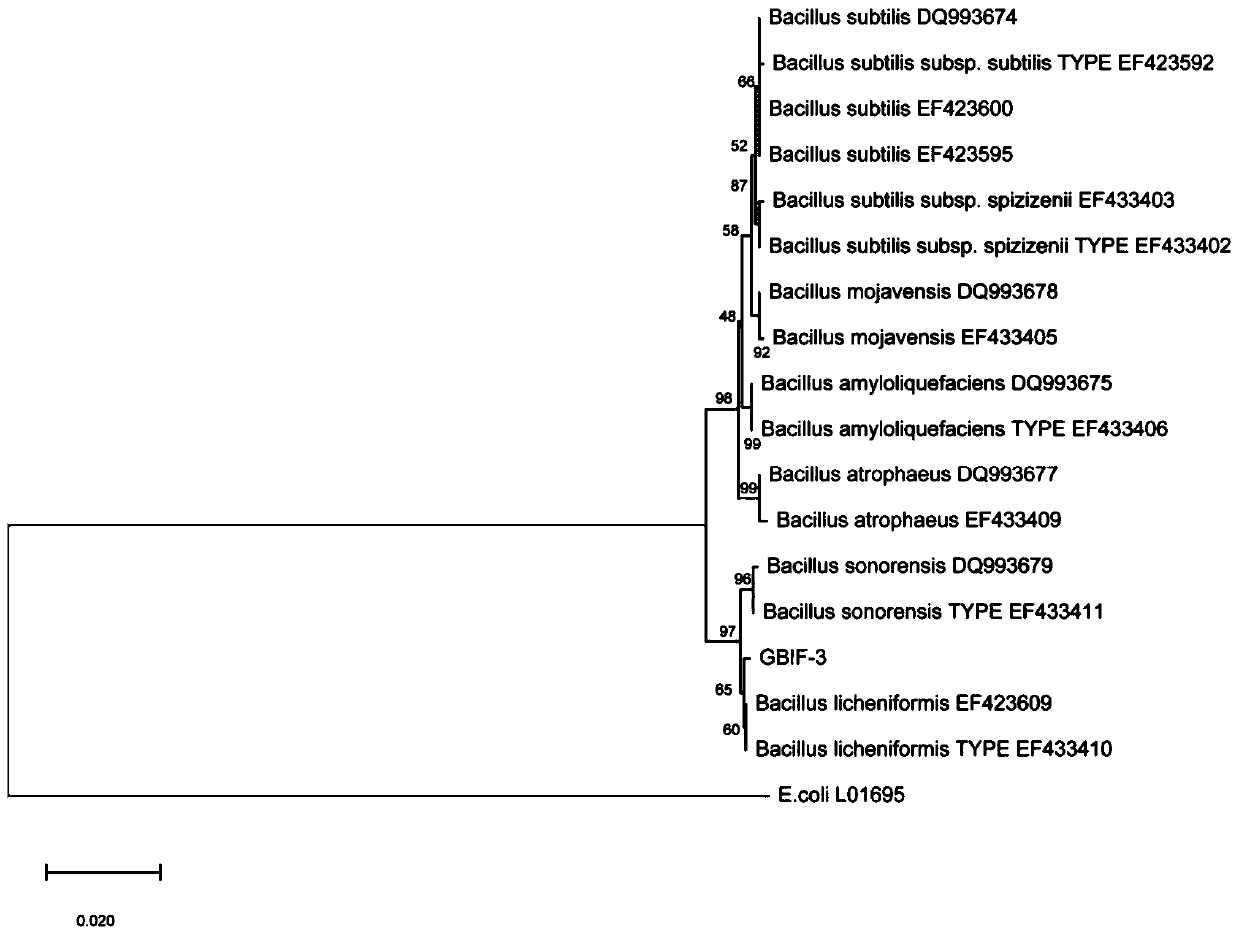

[0044] Screening of high-temperature composting strains from filter mud:

[0045] The strain samples were derived from the mixed materials at the high temperature stage of the filter mud composting test at Maoyuan Sugar Industry Co., Ltd., Wengyuan County, Shaoguan City, Guangdong Province at a temperature of 50°C to 70°C. Weigh 10 g of bacterial strain samples, pass through a liquid enrichment medium with filter mud as the only nutrient source for one week (liquid enrichment medium is: 10 g of filter mud that has been dried to constant weight and crushed and passed through a 10-mesh sieve, added sterile water 90mL; Among them, the filter mud is from the filter mud formed by the sulfurous acid sugar production process of Maoyuan Sugar Industry Co., Ltd., Wengyuan County, Shaoguan City, Guangdong Province, the same below) to continue enrichment, after 3 days of enrichment, draw 10mL of enrichment solution to inoculate Continue to culture the second generation in the new liquid ...

Embodiment 2

[0053] Preparation of bacterial agent LC for high temperature composting of filter sludge

[0054] Inoculate the Bacillus licheniformis strain GBIF-3 on LB medium, shake and culture at 50°C and 170rpm for 1 to 2 days, centrifuge, remove the supernatant to get the precipitate, and then reconstitute it with 100mL of 0.9% sterilized normal saline Suspend to obtain the bacterial bacterial liquid, adjust the bacterial OD value of the bacterial bacterial liquid to 0.5; mix 85% of the bacterial bacterial liquid, 5% of bagasse, 5% of bagasse biochar and 5% of sugarcane molasses according to the mass fraction to obtain bacterial agent LC.

[0055] LB medium is: peptone 10g, yeast powder 5g, NaCl 10g, agar 20g, water 1000mL, pH natural.

[0056] The bagasse is the bagasse obtained by pressing the stalks of the sugarcane sugar factory, which is in a fiber state and is about 20 mesh; the bagasse biochar is prepared from bagasse after anaerobic combustion at 500°C for 2 hours, and is about...

Embodiment 3

[0058] Determination of LC Enzyme Activity of High Temperature Composting Bacteria from Filter Sludge

[0059] High temperature treatment group: get the bacterium LC that embodiment 2 makes, according to weight ratio 5% (the weight ratio of bacterium LC and filter mud solid fermentation medium 5:100) inoculate to the 100g filter mud solid fermentation medium that is housed Put in a 250mL Erlenmeyer flask, place it in an incubator, and ferment for 30 days at a temperature of 50°C, take samples every day (destructive sampling), centrifuge the fermentation broth at 8000rpm / min, 4°C for 5min; filter to remove bacteria and solid impurities. Crude enzyme solution, assay lignocellulosic enzyme activity and protease activity.

[0060] Normal temperature treatment group: except that the temperature was adjusted from 50°C to 30°C, other operations were the same as the high temperature treatment group.

[0061] Blank control group 1: No bacterial agent LC was added, but an equal amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com