Method for crystallizing ammonium molybdate

A technology of ammonium molybdate and ammonium dimolybdate, which is applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve the problems of large manpower and material resources, a large amount of acid waste liquid, and low purity of finished products, so as to improve the evaporation effect , Refined process flow and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

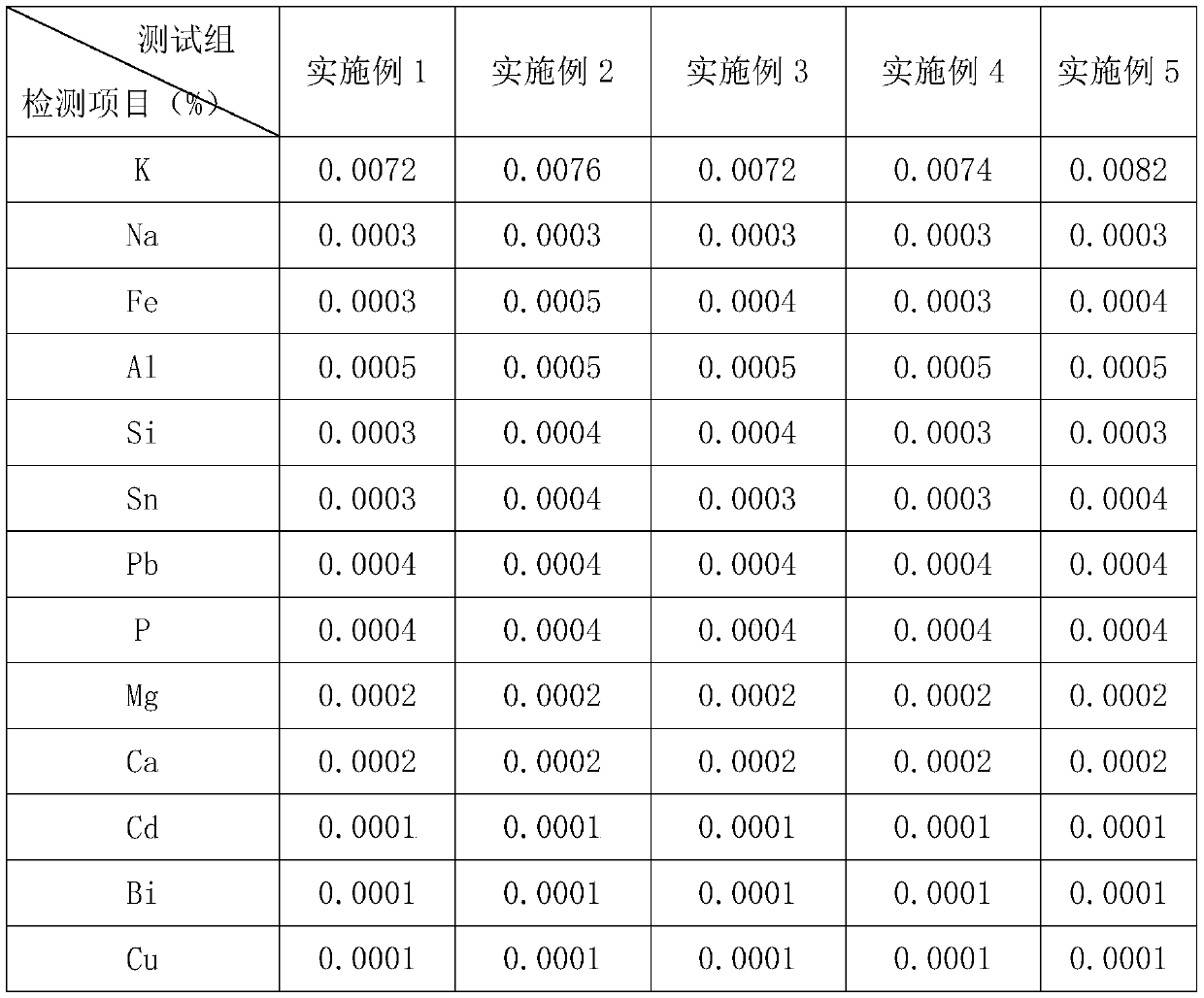

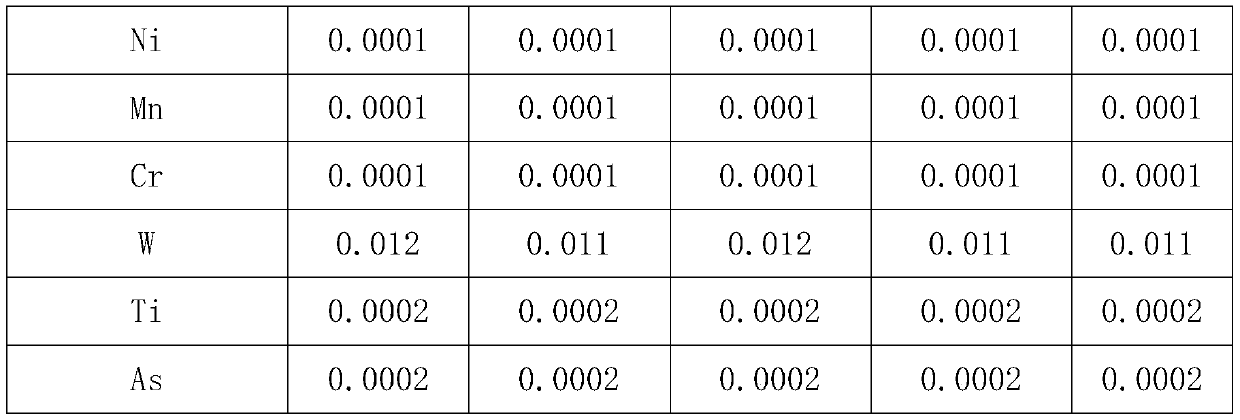

Examples

Embodiment 1

[0037] (S1) Add 2500kg of water and 650kg of acid-washed molybdenum baked sand in the reactor, mix and stir evenly, then add liquid ammonia therein to adjust the pH to 8.5, heat up to 90 degrees Celsius, keep the temperature for 2 hours, and press filter to obtain Ammonia infusion;

[0038] (S2) After cooling the prepared ammonia immersion solution to room temperature, pass through a macroporous acrylic acid series weak acid cation exchange resin to remove metal ions such as calcium, magnesium, aluminum, iron and copper, to obtain a feed solution;

[0039] (S3) Pour the processed feed liquid into the feed liquid tank, open the three-effect evaporation crystallization system, and adjust the parameters such as temperature and vacuum degree of each effect, the evaporator in the evaporation crystallization system is a cross-flow three-effect continuous evaporator, wherein The first effect evaporator and the second effect evaporator are forced circulation continuous evaporators, an...

Embodiment 2

[0047] (S1) Add 2500kg of water and 830kg of acid-washed molybdenum baked sand in the reactor, mix and stir evenly, then add liquid ammonia therein to adjust the pH to 8.5, heat up to 95 degrees Celsius, keep the temperature for 2 hours, and press filter to obtain Ammonia infusion;

[0048] (S2) After cooling the prepared ammonia immersion solution to room temperature, pass through a macroporous acrylic acid series weak acid cation exchange resin to remove metal ions such as calcium, magnesium, aluminum, iron and copper, to obtain a feed solution;

[0049] (S3) Pour the processed feed liquid into the feed liquid tank, open the three-effect evaporation crystallization system, and adjust the parameters such as temperature and vacuum degree of each effect, the evaporator in the evaporation crystallization system is a cross-flow three-effect continuous evaporator, wherein The first effect evaporator and the second effect evaporator are forced circulation continuous evaporators, an...

Embodiment 3

[0057] (S1) Add 2500kg of water and 625kg of acid-washed molybdenum baked sand in the reactor, mix and stir evenly, then add liquid ammonia therein to adjust the pH to 8.5, heat up to 93 degrees Celsius, keep the temperature for 2 hours, and press filter to obtain Ammonia infusion;

[0058] (S2) After cooling the prepared ammonia immersion solution to room temperature, pass through a macroporous acrylic acid series weak acid cation exchange resin to remove metal ions such as calcium, magnesium, aluminum, iron and copper, to obtain a feed solution;

[0059] (S3) Pour the processed feed liquid into the feed liquid tank, open the three-effect evaporation crystallization system, and adjust the parameters such as temperature and vacuum degree of each effect, the evaporator in the evaporation crystallization system is a cross-flow three-effect continuous evaporator, wherein The first effect evaporator and the second effect evaporator are forced circulation continuous evaporators, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com