Hard carbon cathode material and preparation method thereof, and application of hard carbon cathode material

A technology of negative electrode material and hard carbon, applied in the field of hard carbon negative electrode material and its preparation, can solve the problems of large initial irreversible capacity loss, low initial coulombic efficiency, low battery discharge capacity, etc., achieving low cost, improving initial coulombic efficiency, The effect of prolonging the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

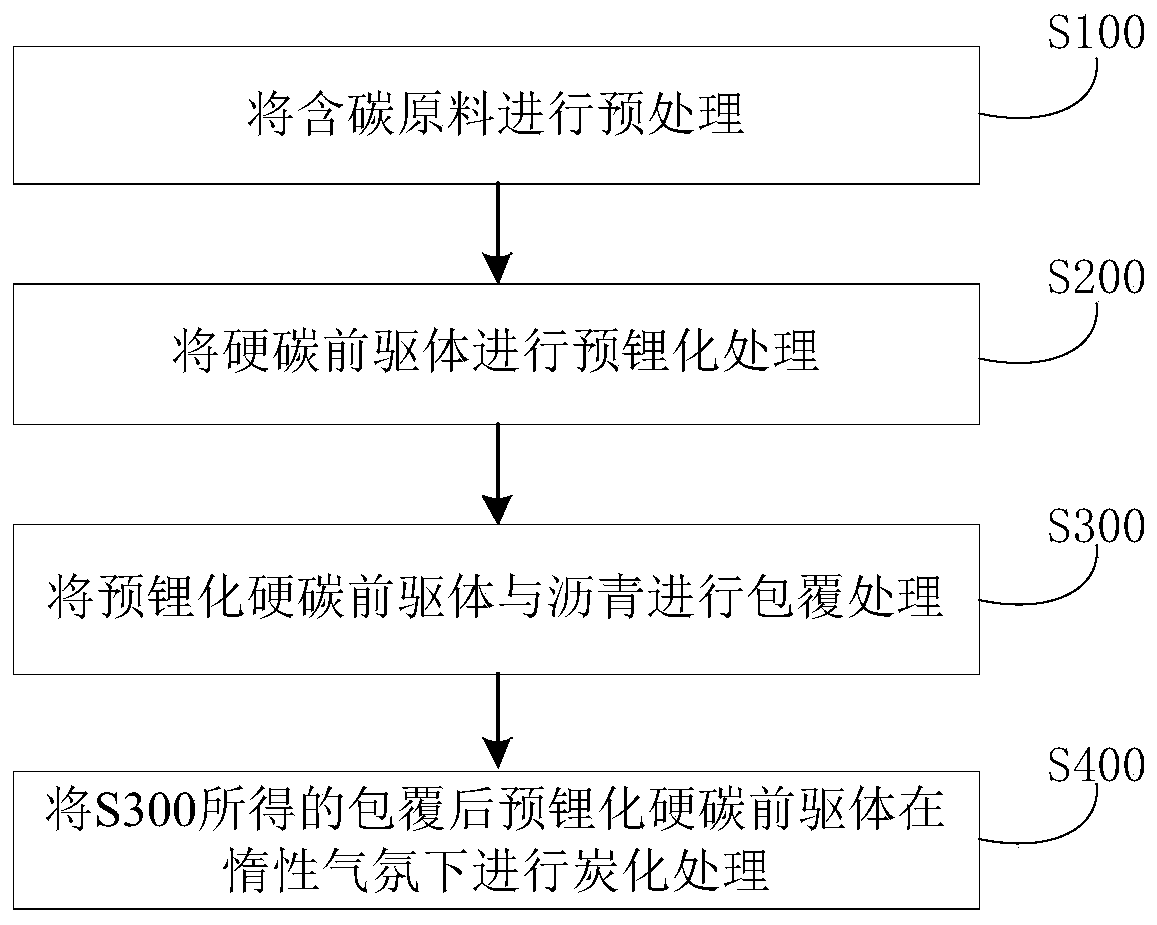

Method used

Image

Examples

preparation example Construction

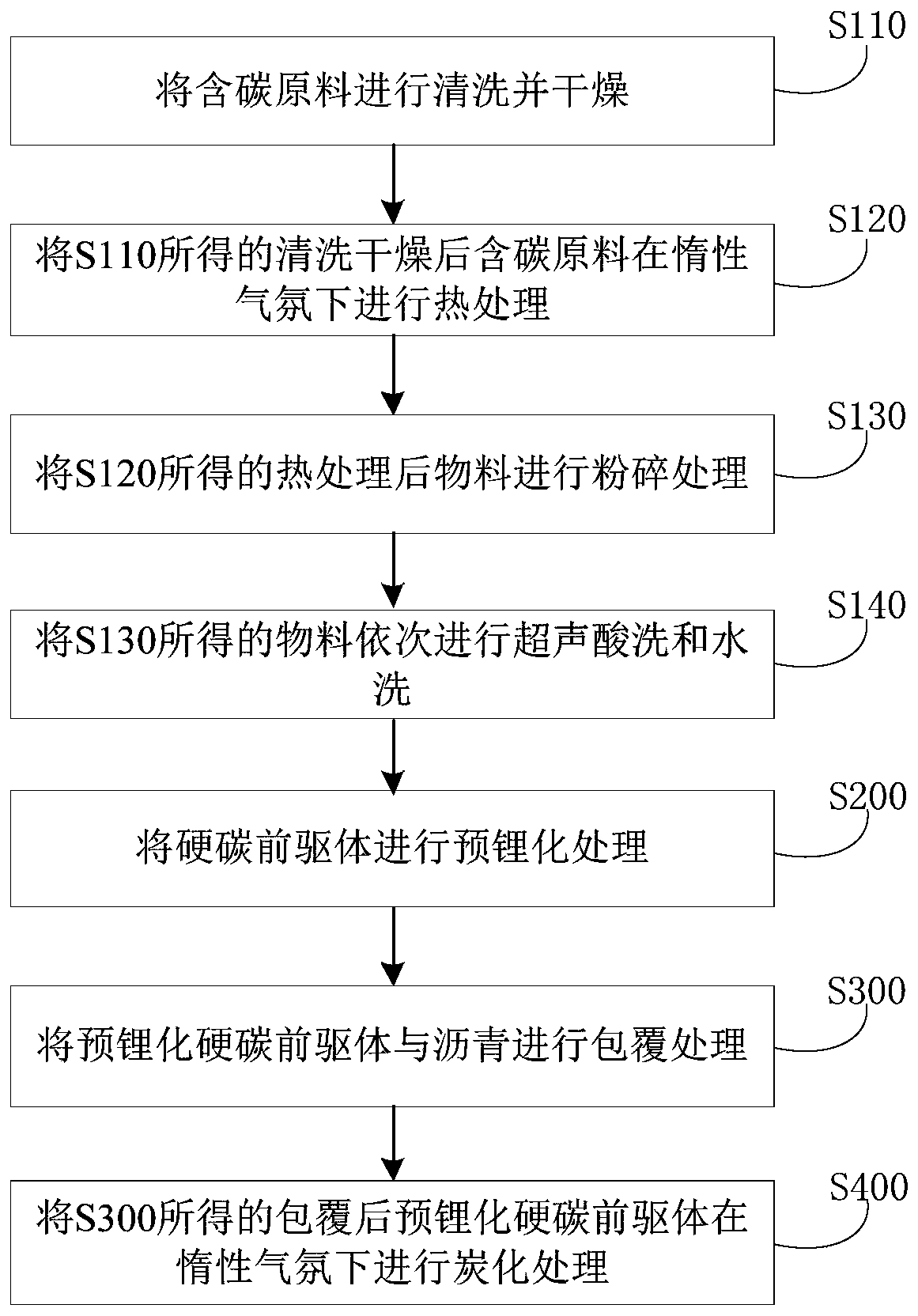

[0056] According to the method for preparing a hard carbon negative electrode material in the embodiment of the present invention, by pretreating the carbon-containing raw material, the impurities in the carbon-containing raw material can be removed, and the carbon-containing raw material can be converted into an amorphous structure cross-linked accumulation At the same time, the source of carbon-containing raw materials is wide and the cost is low, which is conducive to reducing the preparation cost of hard carbon precursors; by pre-lithiation treatment of hard carbon precursors, the surface of hard carbon precursors is coated with lithium-containing substances , Lithium-containing substances can be consumed when the SEI film is formed on the negative electrode interface during battery formation, thereby avoiding the consumption of lithium ions extracted from the electrolyte and positive electrode materials during the formation of the SEI film, thereby improving the capacity of...

Embodiment 1

[0062] Wash and float 100g of rice husk for 10 minutes to remove dust and other solid particles, and then send it to a vacuum drying oven to dry at 105 degrees Celsius; heat-treat the cleaned and dried carbon-containing raw materials in an inert atmosphere of nitrogen. The temperature is 800 degrees centigrade, and the time is 2 hours; after cooling, the heat-treated material is pulverized by a ball mill to obtain a pulverized material with a particle size of D50=15 μm; the pulverized material is ultrasonically pickled for 1 hour by using 100 ml of hydrochloric acid with a concentration of 10 wt%. Then the material after ultrasonic pickling is washed with water until the pH value of the washing solution is neutral, and the hard carbon precursor is obtained after drying at 105 degrees Celsius; 25g of the hard carbon precursor is added to 66g of concentration and stirred in lithium acetate of 10wt%, and then gradually added 26g of ammonium fluoride with a concentration of 10wt%, ...

Embodiment 2

[0065] Wash and float 100g of reed stalks for 10 minutes to remove dust and other solid particles, and then send it to a vacuum drying oven to dry at 105 degrees Celsius; heat-treat the cleaned and dried carbon-containing raw materials in an inert atmosphere of argon , the temperature of the heat treatment is 900 degrees centigrade, and the time is 2h; after cooling, a ball mill is used to pulverize the heat-treated material to obtain a pulverized material with a particle size of D50=13 μm; the pulverized material is ultrasonically pickled by 100 ml of hydrochloric acid with a concentration of 10 wt%. 1h, then wash the material after ultrasonic pickling with water until the pH value of the washing solution is neutral, and obtain a hard carbon precursor after drying at 105 degrees Celsius; 25g of the hard carbon precursor is added to 66g of concentration and stirred in lithium acetate of 10wt%. Gradually add 26g of ammonium fluoride with a concentration of 10wt%, mix and stir, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com