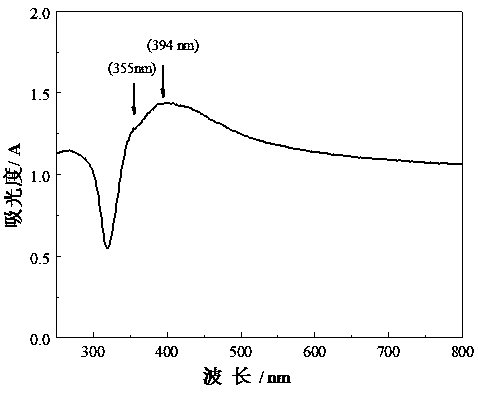

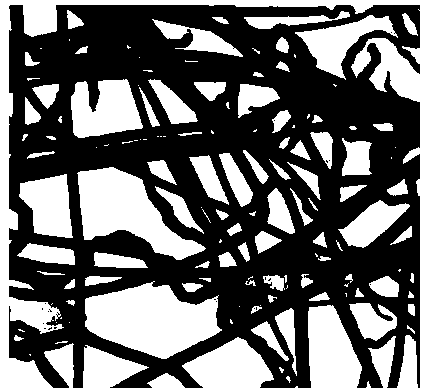

Method for green preparing of high-draw-ratio silver nano wire through composite soft template process

A high aspect ratio, silver nanowire technology, applied in the field of preparation of noble metal nanomaterials, can solve the problems of complex preparation process, many reaction by-products, high energy consumption, etc., and achieve simple preparation method, good uniformity and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Under stirring conditions, weigh 30.0 g of polyvinyl alcohol (polymerization degree is 1700, alcoholysis degree is 98%) and slowly add 900 mL of deionized water at 25±2°C, fully stir and disperse for 15 minutes, then gradually raise the temperature to Incubate at 95°C for 30 minutes, cool naturally after the polyvinyl alcohol is completely dissolved, then dilute to 1000 mL, and prepare a polyvinyl alcohol aqueous solution with a mass concentration of 3.0%.

[0043] Weigh 11.8 g of succinic acid in 100 mL of deionized water, and dissolve to obtain an aqueous solution of succinic acid.

[0044] Under the condition of stirring, add 100 mL of polyvinyl alcohol solution to the aqueous solution of succinic acid, and after mixing thoroughly, set the volume to 1000 mL, adjust its pH value to 5.4, and obtain the mixed soft template of succinic acid-polyvinyl alcohol solution.

[0045] Weigh 3.398 g of silver nitrate and dissolve it in 100 mL of deionized water to prepare a s...

Embodiment 2

[0050] 1) Under the condition of stirring, weigh 10.0 g of polyvinyl alcohol buffer (polymerization degree is 1800, alcoholysis degree is 96%) and slowly add it into 900 mL of deionized water at 25±2°C, fully stir and disperse for 10 minutes, then gradually increase the temperature Incubate at 95°C for 20 minutes, cool naturally after the polyvinyl alcohol is completely dissolved, then set the volume to 1000 mL, and prepare a polyvinyl alcohol aqueous solution with a mass concentration of 1.0% for use.

[0051] Weigh 13.2 g of glutaric acid in 100 mL of deionized water, and dissolve to obtain glutaric acid aqueous solution. Oxalic acid can also be substituted for glutaric acid in this example.

[0052] Under the condition of stirring, add 100 mL of polyvinyl alcohol solution to the glutaric acid aqueous solution, after mixing thoroughly, set the volume to 1000 mL, adjust its pH to 5.2, and obtain the mixed solution of glutaric acid-polyvinyl alcohol composite soft template . ...

Embodiment 3

[0058] 1) Under stirring conditions, weigh 50.0 g of polyvinyl alcohol (polymerization degree is 1700, alcoholysis degree is 96%) and slowly add 900ml of deionized water at about 25°C, fully stir and disperse for 15 minutes, then gradually raise the temperature to 95°C Keep warm at ℃ for 30 minutes, cool naturally after the polyvinyl alcohol is completely dissolved, then set the volume to 1000 ml, and prepare a polyvinyl alcohol aqueous solution with a mass concentration of 5.0%.

[0059] Weigh 5.0 g of malonic acid and 15 g of adipic acid in 100 mL of deionized water, dissolve them to obtain malonic acid-adipic acid aqueous solution.

[0060] Under the condition of stirring, add 100 ml of polyvinyl alcohol solution to the aqueous solution of malonic acid-adipic acid, after mixing thoroughly, set the volume to 1000 ml, adjust its pH value to 5.5, and obtain malonic acid-adipic acid- Mixed solution of polyvinyl alcohol composite soft template.

[0061] Weigh 16.55 g of silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com