Inkjet printing microcapsule pigment ink based on multi-layer self-assembly, and preparation method thereof, and printing molding process on cotton fabrics

A technology of inkjet printing and pigment ink, applied in pigment paste, ink, dyeing method, etc., can solve problems such as insufficient hiding power, reduce ink bleeding, improve hiding power, improve biocompatibility and dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

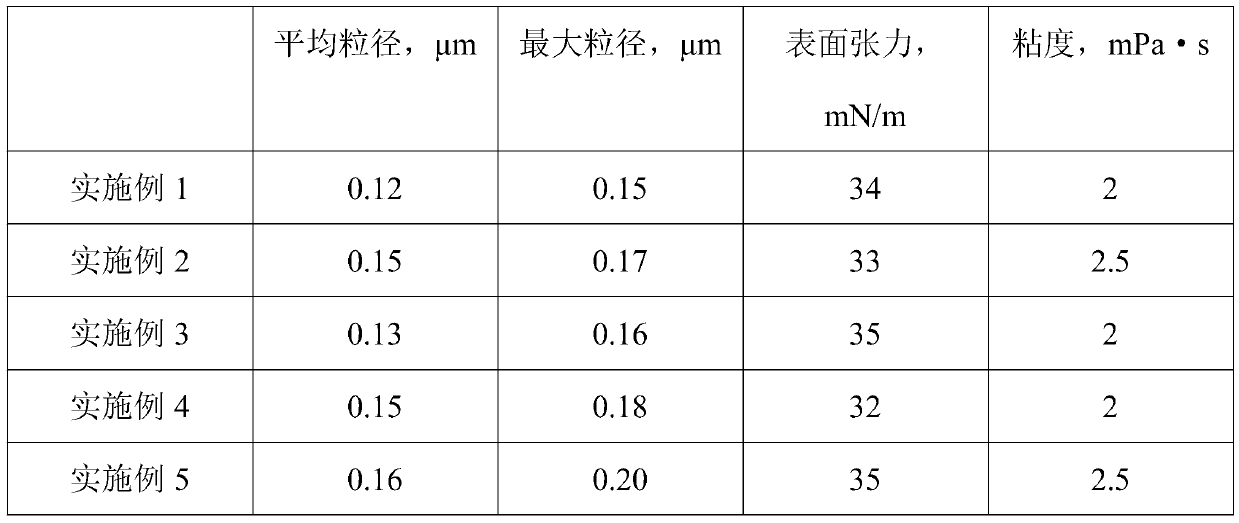

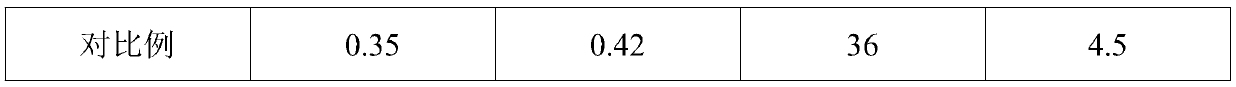

Examples

Embodiment 1

[0037] A preparation method of inkjet printing microcapsule pigment ink based on multilayer self-assembly, comprising the following steps:

[0038] (1) In parts by weight, after mixing 3 parts of pigments, 1 part of polyvinyl alcohol, 0.1 part of sodium dodecylbenzenesulfonate, and 50 parts of deionized water, stir and mix for 3 hours at 1500 rpm to prepare To obtain a pigment dispersion; then add 1 part of ethyl orthosilicate to the pigment dispersion, stir and hydrolyze for 10 h at 50 ° C, cool to room temperature after the reaction, and prepare a microcapsule pigment dispersion, and continue to add 1 part of N, N methylenebisacrylamide, stirred and mixed to obtain an activated microcapsule pigment dispersion;

[0039] (2) Mix and stir 6 parts of acrylamide monomer, 0.35 parts of sodium dodecylbenzenesulfonate, and 30 parts of deionized water to prepare an acrylamide emulsion, which is added to 100 parts of activated microcapsule pigment dispersion , stirred and mixed for 3...

Embodiment 2

[0044] A preparation method of inkjet printing microcapsule pigment ink based on multilayer self-assembly, comprising the following steps:

[0045] (1) In parts by weight, after mixing 8 parts of pigments, 4 parts of polyvinyl alcohol, 0.6 parts of sodium dodecylbenzene sulfonate, and 80 parts of deionized water, they were stirred and mixed for 3 hours at 1500 rpm to prepare Obtain a pigment dispersion; then add 1 part of ethyl orthosilicate to the pigment dispersion, stir and hydrolyze for 20 hours at 50°C, cool to room temperature after the reaction, and prepare a microcapsule pigment dispersion, continue adding 2 parts of N, N methylenebisacrylamide, stirred and mixed to obtain an activated microcapsule pigment dispersion;

[0046] (2) Mix and stir 11 parts of acrylamide monomer, 0.35 parts of sodium dodecylbenzenesulfonate, and 40 parts of deionized water to prepare an acrylamide emulsion, which is added to 100 parts of activated microcapsule pigment dispersion , stirred ...

Embodiment 3

[0051] A preparation method of inkjet printing microcapsule pigment ink based on multilayer self-assembly, comprising the following steps:

[0052] (1) In parts by weight, after mixing 4 parts of pigments, 1.5 parts of polyvinyl alcohol, 0.2 parts of sodium dodecylbenzenesulfonate, and 60 parts of deionized water, they were stirred and mixed for 3 hours at 1500 rpm to prepare Obtain a pigment dispersion; then add 1 part of tetraethyl orthosilicate to the pigment dispersion, stir and hydrolyze for 12 hours at 50°C, cool to room temperature after the reaction is complete, and prepare a microcapsule pigment dispersion, continue adding 1.2 parts of N,N methylenebisacrylamide, stirred and mixed to obtain an activated microcapsule pigment dispersion;

[0053] (2) Mix and stir 7 parts of acrylamide monomer, 0.35 parts of sodium dodecylbenzenesulfonate, and 32 parts of deionized water to prepare an acrylamide emulsion, which is added to 100 parts of activated microcapsule pigment disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com