Epitaxial growth method for reducing interface thermal resistance of gallium nitride high-electron-mobility field-effect transistor

A technology of high electron mobility and epitaxial growth, which is applied in the field of epitaxial growth to reduce the interface thermal resistance of GaN high electron mobility field effect transistors, and can solve the problem of deterioration, unfavorable lateral merging of nucleation layers, and thinning material quality, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

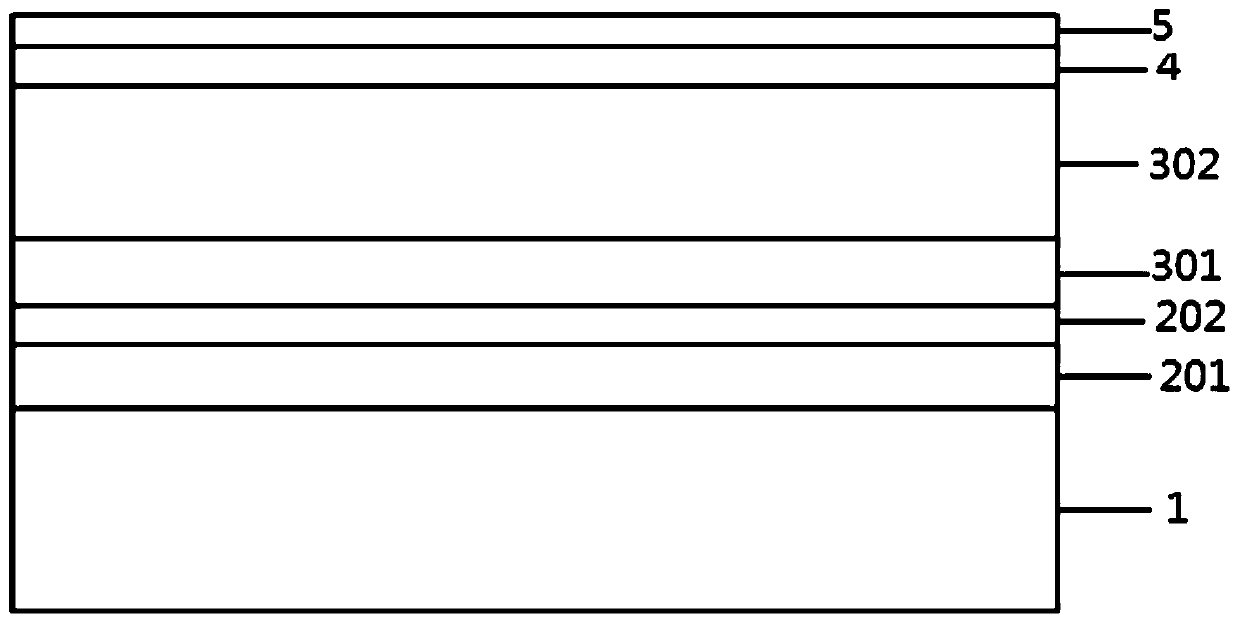

[0039] An epitaxial growth method for reducing the interface thermal resistance of GaN high electron mobility field effect transistors, comprising the following steps:

[0040] (1) Place a 3-inch silicon carbide single crystal substrate on the base of a metal-organic compound chemical vapor deposition (MOCVD) device for epitaxial material growth, set the reaction chamber pressure to 80torr, and the flow rate of hydrogen to 80slm, and the system is heated to 1070°C and maintain the temperature for 8 minutes to remove the contamination on the substrate surface;

[0041] (2) Keep the pressure of the reaction chamber and the flow rate of hydrogen gas constant, continue to heat up to 1140 ° C, feed ammonia gas with a flow rate of 4 slm and keep it for 1 minute, and nitride the substrate;

[0042] (3) keep the reaction chamber pressure, hydrogen flow rate, ammonia flow rate and temperature constant, feed trimethylaluminum with a flow rate of 200 sccm, grow the lower aluminum nitride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com