Micro-nano super-hydrophobic film on metal substrate surface, preparation method and application thereof

A metal substrate, super-hydrophobic technology, applied in metal material coating technology, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of unfavorable mass production, high cost, multi-energy, etc., to save preparation time and Manpower, preparation cost saving, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

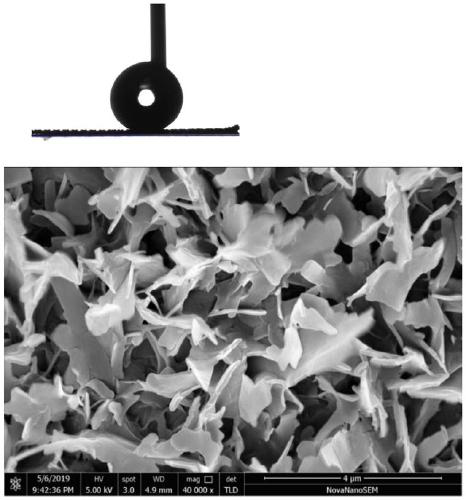

[0063] Add sodium stearate into distilled water, stir and heat to dissolve it, configure it into an aqueous solution of sodium stearate with a concentration of 0.0005 mol / L, and cool to room temperature for use. After the phosphor bronze mesh is cleaned with detergent, rinse it with pure water for 3 times, blow it dry with nitrogen, immerse it in the above aqueous solution of sodium stearate, and react it in a water bath at 25°C for 18 hours. After the reaction, put the phosphorus The copper grid was washed three times with ethanol and distilled water respectively, and dried with nitrogen. Then the contact angle and SEM tests were carried out on the hydrophobic surface of the phosphor copper mesh sample.

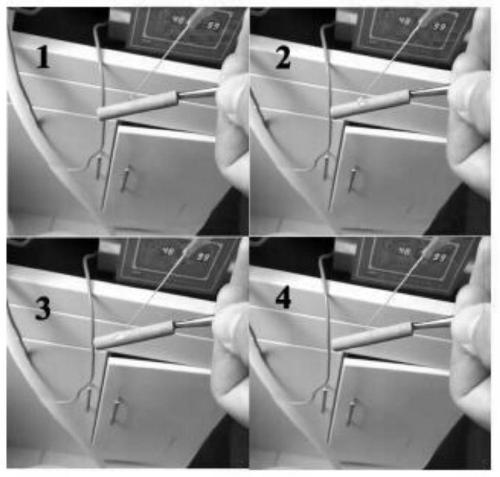

[0064] The contact angle test method is: under the condition of 25 ℃ temperature, using the optical contact angle measuring instrument (SPCAX 3 series, Beijing Hake, China) take three measurements on different parts of the prepared sample surface, and calculate the average ...

Embodiment 2

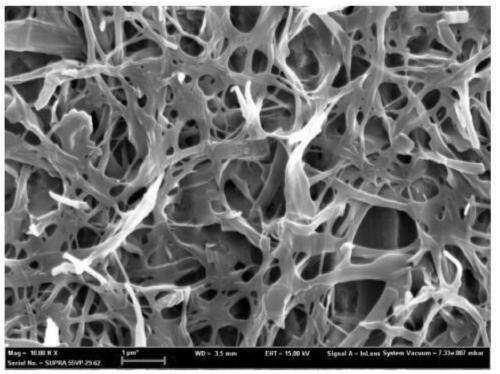

[0067] Add sodium stearate into distilled water, stir and heat to dissolve it, configure it into an aqueous sodium stearate solution with a concentration of 0.001mol / L, and cool it to room temperature for later use. Copper tube 8mm (diameter) × 0.35mm (wall thickness) × 40mm (length) through 0.5mol / L NaHCO 3 After ultrasonic cleaning of the aqueous solution, rinse with pure water for 3 times, blow dry with nitrogen, then immerse in the above-mentioned sodium stearate aqueous solution, and react in a water bath at 25°C for 19 hours. After the reaction, the copper tube is washed with ethanol and They were washed three times with distilled water and blown dry with nitrogen gas. Then carry out contact angle and SEM test on the hydrophobic sample of the copper tube, the contact angle to water is 159.4°, the SEM photo is as follows figure 2 As shown, the micro-nano superhydrophobic film on the surface of the sample is an irregular strip structure.

Embodiment 3

[0069] Add sodium laurate into distilled water, stir and heat to dissolve it, and configure it into an aqueous solution of sodium laurate with a concentration of 0.003mol / L, and cool it to room temperature for use. Phosphor bronze sheet 1cm (width) × 2cm (length) was washed with acetone, ethanol and 0.1mol / L nitric acid in turn, then immersed in the above sodium laurate aqueous solution, and reacted in a water bath at 25°C for 36 hours. After the reaction, the phosphor copper sheet was washed three times with ethanol and distilled water, and dried with nitrogen gas. Then, the contact angle test was carried out on the hydrophobic sample of phosphor copper sheet, and the contact angle to water was 163.0°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com