Preparation of WO3 (tungsten trioxide) nanoflower material and application of WO3 nanoflower material in gas sensor

A nanomaterial, nanoflower technology, applied in nanotechnology, nanotechnology, analytical materials, etc., can solve problems such as high price, and achieve the effects of good reversibility, good reversibility and selectivity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

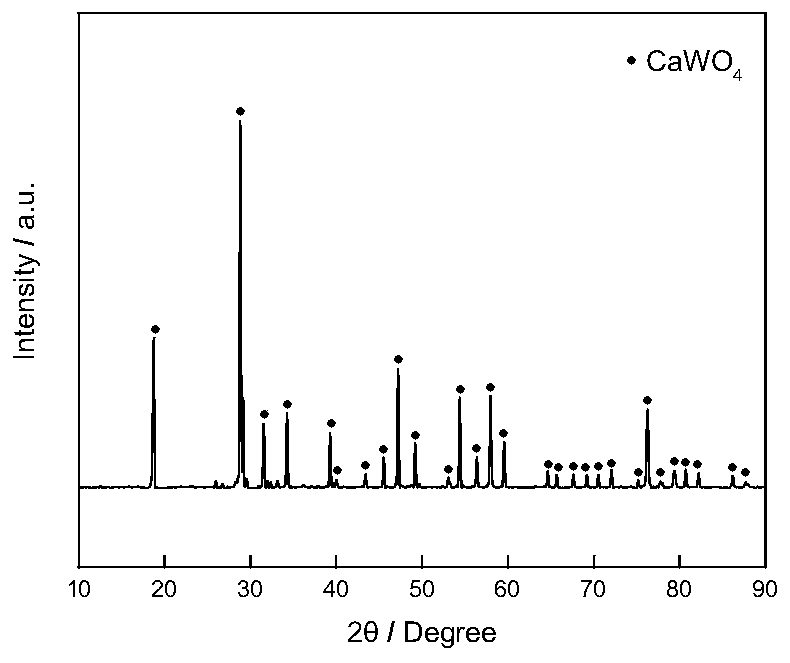

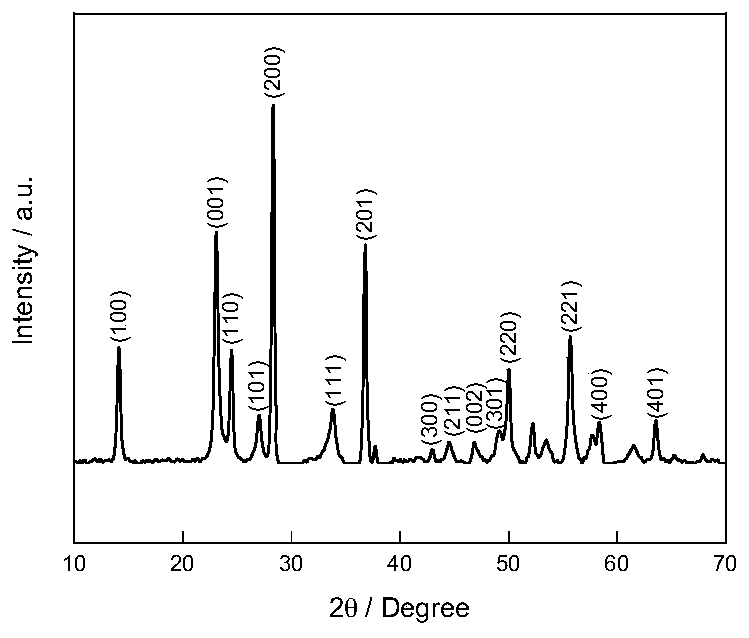

[0037] The invention is a kind of WO which is self-assembled by nanosheets synthesized by using scheelite concentrate. 3 The method of nanoflower and its function in NO 2 Application of gas sensor. The X-ray diffraction pattern of the scheelite concentrate that the present invention adopts is as figure 1 As shown, the results show that the main useful mineral in the scheelite concentrate is CaWO 4 .

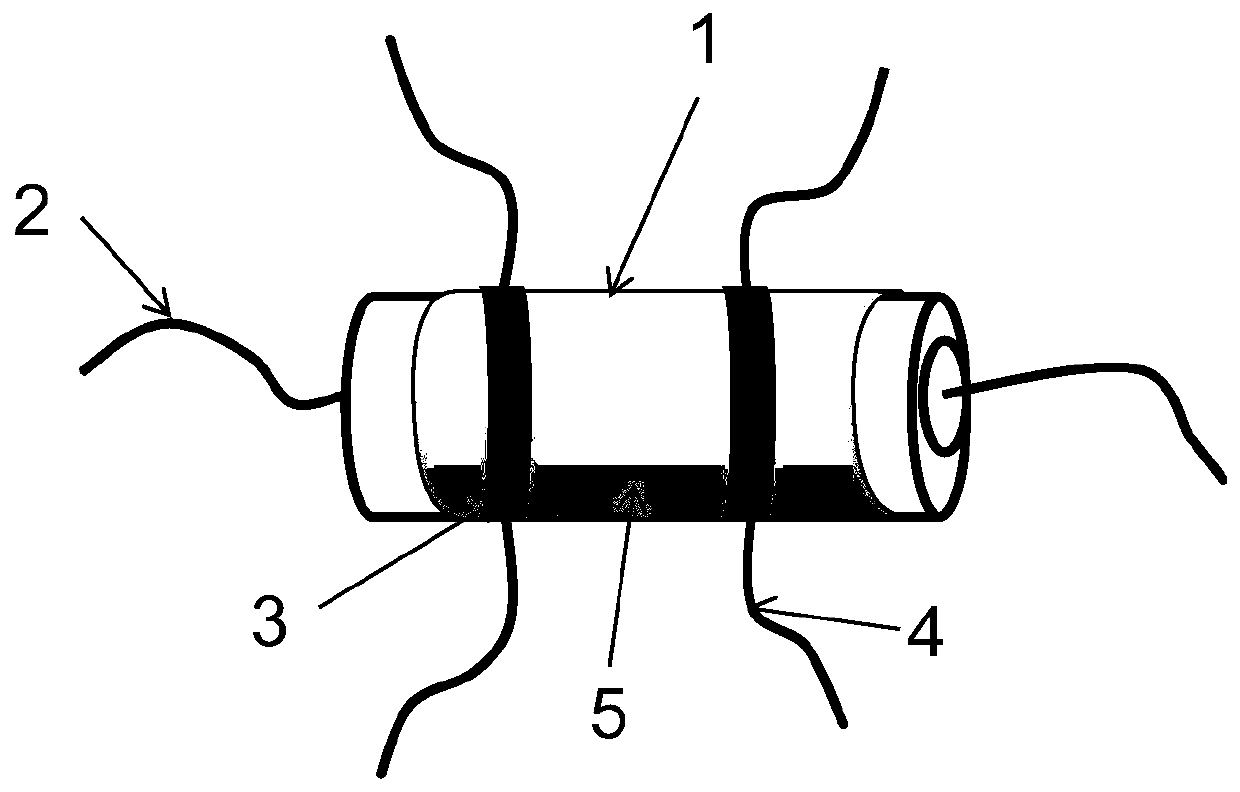

[0038] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 As shown, the Ni-Cr heating wire 2 traverses the Al 2 o 3 The ceramic tube 1 is welded on the heating electrode of the hexagonal base, and the gold electrode 3 is coated on Al 2 o 3 The outer surface of the ceramic tube 1 is welded to the measuring electrode of the hexagonal base through four platinum wires 4 , and the gas-sensitive coating 5 is coated on the gold electrode 3 and the outer surface of the cerami...

Embodiment 2

[0055] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 shown.

[0056] A kind of WO synthesized by self-assembly of nanosheets from scheelite concentrate 3 Preparation method of nanoflowers and NO 2 Gas sensor, follow the steps below:

[0057] ①Extract tungsten from scheelite concentrate by using sodium hydroxide leaching process: place scheelite concentrate in a NaOH solution with a concentration of 15mol / L, at a liquid-solid ratio of 2:1, a reaction temperature of 170°C, and a stirring speed of 600rpm , holding time of 180min under the experimental conditions, filter the obtained leaching product to obtain filtrate and leaching residue, wash the leaching residue with deionized water 3 times to obtain washing liquid, and mix the obtained filtrate and the obtained washing liquid to obtain tungsten-containing The leachate of acid radical ions, the concentration of W in...

Embodiment 3

[0065] A gas-sensitive coating is WO self-assembled from nanosheets 3 The gas sensor of nanoflowers, the schematic diagram of its structure is as follows figure 2 shown.

[0066] A kind of WO synthesized by self-assembly of nanosheets from scheelite concentrate 3 Preparation method of nanoflowers and NO 2 Gas sensor, follow the steps below:

[0067] ①Extract tungsten from scheelite concentrate by using sodium hydroxide leaching process: place scheelite concentrate in NaOH solution with a concentration of 18mol / L, at a liquid-solid ratio of 3:1, a reaction temperature of 190°C, and a stirring speed of 700rpm , holding time of 30min under the experimental conditions, the obtained leaching product is filtered to obtain the filtrate and leaching residue, the leaching residue is washed with deionized water 3 times to obtain the washing liquid, and the obtained filtrate and the obtained washing liquid are mixed to obtain a tungsten-containing The leachate of acid radical ions, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com