Alloy target material containing rare earth elements and preparation method thereof

A technology of rare earth elements and alloy targets, which is applied in the field of alloy targets containing rare earth elements and its preparation, which can solve the problem of difficulty in ensuring the uniformity of composition and structure in alloys, and the difficulty in obtaining high-quality and high-density targets and hot-pressed targets Uneven density distribution and other problems, to achieve the effect suitable for large-scale industrial production and application, with many specifications and sizes, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

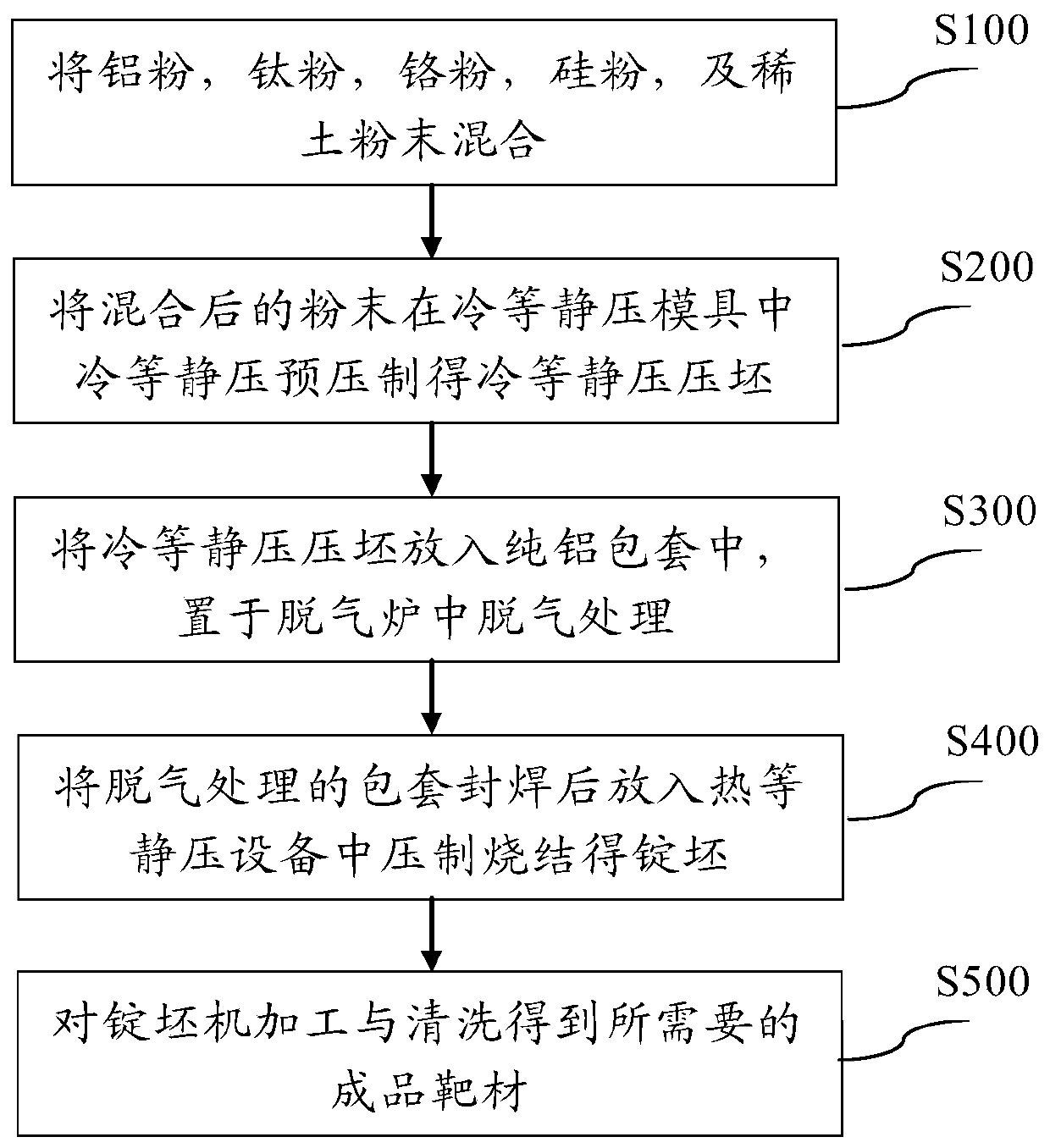

[0028] see figure 1 , a preparation method of an alloy target containing rare earth elements provided by the present invention, comprising the following steps:

[0029] S100: In atomic percentage, mix 30-80at% aluminum powder, 1-30% titanium powder, 1-30% chromium powder, 1-20at% silicon powder, and 0.1-10at% rare earth powder;

[0030] S200: cold isostatic pre-pressing the mixed powder in a cold isostatic pressing mold to obtain a cold isostatic compact;

[0031] S300: put the cold isostatic pressed compact into a pure aluminum sheath, and place it in a degassing furnace for degassing;

[0032] S400: sealing and welding the degassed sheath into a hot isostatic pressing device to press and sinter an ingot;

[0033] S500: Machining and cleaning the ingot to obtain the required finished target material.

[0034] Wherein, the purity of the aluminum powder, titanium powder, chromium powder, silicon powder, and rare earth powder is above 99.5%, the particle diameter of the alumi...

example 1

[0042] The aluminum-chromium-titanium-silicon-yttrium alloy target of the present invention is made of the following atomic percentages of raw materials: 75% aluminum, 10% titanium, 9% chromium, 5.5% silicon, and 0.5% yttrium oxide; the preparation method of the alloy target in this example, Include the following steps:

[0043] (1) Take by weighing 99.5% purity, chromium powder and titanium powder with an average particle size of 75 μm, aluminum powder with an average particle size of 63 um, silicon powder with an average particle size of 45 um, and yttrium oxide powder with an average particle size of 40 um in three-dimensional Mix in the mixer for 3 hours, and fill with high-purity argon for protection during the mixing process;

[0044] (2) Pack the mixed powder into the cold isostatic pressing molding mold and carry out cold isostatic pressing pre-compression molding, the pressure of cold isostatic pressing is 100MPa, and the pressure is maintained for 10 minutes;

[004...

example 2

[0050] The aluminum-chromium-titanium-silicon-cerium alloy target of the present invention is made of the raw materials of the following atomic percentages: aluminum 65%, titanium 15%, chromium 10%, silicon 5%, cerium 5%; the preparation method of the alloy target of this example includes the following step:

[0051] (1) Take by weighing 99.5% purity, chromium powder and titanium powder with an average particle diameter of 80 μm, aluminum powder with an average particle diameter of 65 μm, silicon powder with an average particle diameter of 45 μm, and cerium powder with an average particle diameter of 45 μm in a three-dimensional mixing Mix in the feeder for 3 hours, and fill in high-purity argon for protection during the mixing process;

[0052] (2) Pack the mixed powder into the cold isostatic pressing molding mold and carry out cold isostatic pressing pre-compression molding, the pressure of cold isostatic pressing pre-compression is 80MPa, and the pressure is maintained for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com