High-performance feather degrading bacterium and application thereof

A feather and strain technology, applied in the field of microorganisms, can solve unseen problems and achieve the effects of high production efficiency, increased yield and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: the screening of chryseobacterium X-Y4

[0063] (1) Sample source: Soil samples from pigeon farms where rotten feathers have been piled up for a long time.

[0064] (2) Strain screening:

[0065] The screening process includes the following steps:

[0066] a. Preparation of selection medium

[0067] b. Primary screening of feather-degrading bacteria

[0068] c. Re-screening of feather-degrading bacteria

[0069] The step a may further include: preparing feather solid culture medium and preparing feather liquid culture medium.

[0070] The step b may further include: from the air-dried pigeon plant soil sample, weigh 5g of soil and add it to 50ml of sterile water for enrichment culture, and cultivate it at 30°C and 160r / min for 12h; take the enrichment culture solution and press 10 -1 、10 -2 , 10 -3 、10 -4 、10 -5 、10 -6 、10 -7 、10 -8 Gradient dilution was spread on the feather solid medium, and when a single colony grew out, it was purified and...

Embodiment 2

[0077] Embodiment 2: strain identification.

[0078] 16sRNA sequence analysis method: PCR amplification uses bacterial 16sRNA universal primers:

[0079] 27F5'-AGAGTTTGATCMTGGCTCAG-3'

[0080] 1492R5'-GGTTACCTTGTTACGACTT-3'

[0081] dNTP (2 μL), primer F (2 μL), primer R (2 μL), Taq DNA polymerase (0.25 μL), deionized water (37.75 μL). Reaction conditions: pre-denaturation at 95°C for 10 minutes, deformation at 95°C for 30s, annealing at 55°C for 30s, extension at 72°C for 30s, a total of 25 cycles, and full extension at 72°C for 10 minutes.

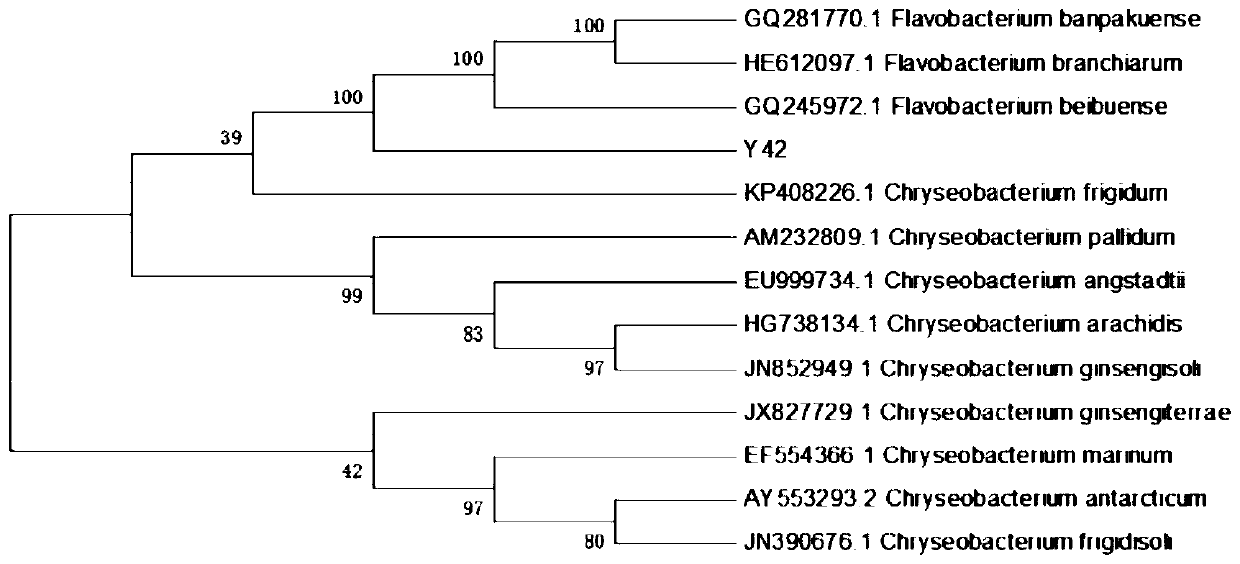

[0082] Most of the 16S rDNA sequence was determined, as shown in SEQ ID No:1. The base sequences of the measured sequences were compared with BLAST on the NCBI website, and a phylogenetic tree based on the complete sequence of 16S rRNA was constructed. The results showed that the strain was 98% homologous to Chrysobacterium aureus. Therefore, it is determined that the present invention uses Flavobacterium tirrenicum, and the specifi...

Embodiment 3

[0083] Embodiment 3: the culture condition optimization of feather degrading strain

[0084] (1) bacterial strain: the bacterial strain Flavobacterium tirrenicum X-Y4 that embodiment 1 screens out

[0085] (2) Method steps:

[0086] A single factor test was used to investigate the effects of the strain's feather addition amount, shaker speed, initial pH, inoculation amount and fermentation temperature on the soluble protein yield.

[0087] a. Optimal test of feather addition amount

[0088] The fermentation conditions were 100mL / 250mL of feather liquid culture medium, 2% (v / v) inoculum size, 30°C, 160r / min, pH=7.0, 72h of shake flask fermentation, and the filling amount of feather was 0.5, 1.0g, 1.5g, 2.0g, 2.5g and 3.0g.

[0089] b. Optimization experiment of shaking table speed

[0090] The amount of feather added is based on the optimal result determined by the above test. Other fermentation conditions are 100mL / 250mL of feather liquid culture medium, 2% (v / v) inoculum,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com