Magnetic sulfur, iron and carbon compound porous environment-friendly material and green preparing method and application thereof

An environmentally friendly material and carbon composite technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of expensive preparation of water purification materials, limited practical application, time-consuming environment, etc. , good magnetism, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

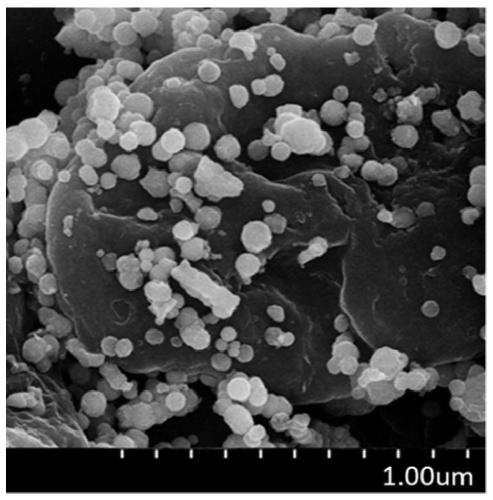

Image

Examples

Embodiment 1

[0032] Preparation of magnetic sulfur-iron-carbon composite porous environmental protection material:

[0033] 1) The green tide algae Enteromorpha salvaged from the beach is ground and homogenized and directly put into the hydrothermal reaction kettle, and at the same time, 0.5% by mass of pyrite powder and 0.01% by mass of dimethyl sulfoxide and cysteine are added The acid is mixed to make a deoxidized sulfur-rich slurry, wherein the final concentration of cysteine in the reaction system is 0.1mol / L;

[0034] 2) Add ferrous sulfate solid, sodium dithionite solid, surface dispersant and bischofite solid to the reaction kettle equipped with deoxygenated sulfur-rich slurry, mix well, and perform a rapid hydrothermal reaction at 170°C in a nitrogen atmosphere for 24 Hour. Among them, the mass ratio of iron and deoxidized sulfur-enriched slurry in the mixed system is controlled at 1:30, the molar ratio of iron to sulfur is controlled at 4:1, and the mass ratio of bischofite ...

Embodiment 2

[0040] Preparation of magnetic sulfur-iron-carbon composite porous environmental protection material:

[0041] 1) Collect cow dung from a farm and put it directly into the hydrothermal reaction kettle, add pyrite powder with a mass ratio of 2%, and mix with dimethyl sulfoxide and cysteine with a mass ratio of 0.04% Make a deoxidized sulfur-rich slurry, wherein the final concentration of cysteine in the reaction system is 0.3mol / L;

[0042] 2) Add ferric chloride solid, ferrous ammonium sulfate solid, surface dispersant and titanium tetrachloride to the reaction kettle equipped with deoxygenated sulfur-rich slurry, mix well, use tartaric acid to spray the slurry and the reaction vessel, and seal the reaction device, rapid hydrothermal reaction at 220°C for 1 hour. Control the mass ratio of iron and deoxidized sulfur-enriched slurry in the mixed system to 1:5, the molar ratio of iron to sulfur to 6:1, and the mass ratio of titanium tetrachloride to deoxidized sulfur-enriche...

Embodiment 3

[0047] Preparation of magnetic sulfur-iron-carbon composite porous environmental protection material:

[0048] 1) The activated sludge obtained from a sewage treatment plant is directly put into the hydrothermal reaction kettle, and at the same time, 5% pyrite powder and 0.1% dimethyl sulfoxide and cysteine are added Acid mixing is made into deoxidized sulfur-rich slurry, wherein the final concentration of cysteine in the reaction system is 0.2mol / L;

[0049] 2) Add ferric sulfate solid, sodium sulfide solid, surface dispersant and magnesium chloride to the reaction kettle equipped with deoxygenated sulfur-rich slurry, mix well, use ascorbic acid to spray the slurry and the reaction vessel, seal the reactor, and quickly Hydrothermal reaction for 8 hours. Control the mass ratio of iron and deoxygenated sulfur-enriched slurry in the mixed system at 1:20, the molar ratio of iron-sulfur at 1:1, the mass ratio of magnesium chloride and deoxygenated sulfur-enriched slurry at 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com