Manganese zinc ferrite core with high saturation magnetic flux density and preparation method thereof

A manganese-zinc ferrite, magnetic flux density technology, applied in magnetic core manufacturing, inductor/transformer/magnet manufacturing, inorganic material magnetism, etc. Zinc ferrite core saturation magnetic flux density decreases and other problems, to achieve the effect of increasing the saturation magnetic flux density, preventing the magnetic core density from decreasing, and increasing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

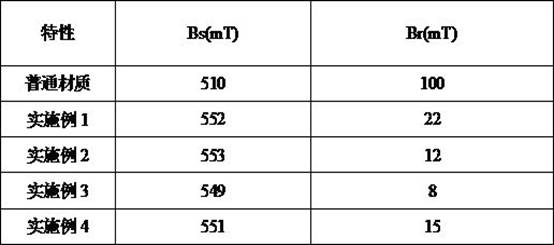

Examples

Embodiment 1

[0039] This embodiment provides a manganese zinc ferrite core with a high saturation magnetic flux density and a preparation method thereof. Specifically, the preparation method of the manganese zinc ferrite core includes the following steps:

[0040](1) According to the mass fraction, weigh the following components: manganese powder 20%, zinc oxide powder 11.9%, silicon dioxide 0.02%, calcium oxide 0.05%, vanadium pentoxide 0.03%, iron powder 68%, and set aside; Wherein, the iron powder is prepared by electrolyzing low-silicon and low-carbon steel under acidic conditions (pH value is 2); the mass content of silicon dioxide in the iron powder is less than 0.01%, and the particle size of the iron powder is less than 100 mesh; the mass content of manganese in the manganese powder is not less than 99.7%, the mass content of silicon in the manganese powder is less than 0.005%, and the particle size of the manganese powder is less than 100 mesh; the mass content of zinc oxide in the...

Embodiment 2

[0050] This embodiment provides a manganese zinc ferrite core with a high saturation magnetic flux density and a preparation method thereof. Specifically, the preparation method of the manganese zinc ferrite core includes the following steps:

[0051] (1) According to the mass fraction, weigh the following components: 15% manganese powder, 9.8% zinc oxide powder, 0.05% silicon dioxide, 0.1% calcium oxide, 0.05% vanadium pentoxide, 75% iron powder, set aside; Wherein, the iron powder is prepared by electrolyzing low-silicon and low-carbon steel under acidic conditions (pH value 3); the mass content of silicon dioxide in the iron powder is less than 0.01%, and the particle size of the iron powder is less than 100 mesh; the mass content of manganese in the manganese powder is not less than 99.7%, the mass content of silicon in the manganese powder is less than 0.005%, and the particle size of the manganese powder is less than 100 mesh; the mass content of zinc oxide in the zinc ox...

Embodiment 3

[0061] This embodiment provides a manganese zinc ferrite core with a high saturation magnetic flux density and a preparation method thereof. Specifically, the preparation method of the manganese zinc ferrite core includes the following steps:

[0062] (1) According to the molar mass fraction, weigh the following components: 18% manganese powder, 9.75% zinc oxide powder, 0.03% silicon dioxide, 0.08% calcium oxide, 0.04% vanadium pentoxide, 73% iron powder, and reserve ; Wherein, the iron powder is prepared by electrolysis of low-silicon and low-carbon steel under acidic conditions (pH value is 2); the mass content of silicon dioxide in the iron powder is lower than 0.01%, and the particle size of the iron powder is less than 100 mesh; the mass content of manganese in the manganese powder is not less than 99.7%, the mass content of silicon in the manganese powder is less than 0.005%, and the particle size of the manganese powder is less than 100 mesh; the mass content of zinc oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com