Preparation method of polypropylene type brush filaments

A technology of polypropylene type and brush filaments, which is applied in the field of brush filaments, can solve problems such as no way to know, and achieve the effects of improving adhesion, stable performance, and improving treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of preparation method of polypropylene type hairbrush filament of the present embodiment, comprises the following steps:

[0029]Step 1, preparation of polypropylene matrix material: soak polypropylene in activated elasticizing solution for 1 hour at a temperature of 65°C, then dry at room temperature, and then perform silane activation treatment;

[0030] Step 2, preparation of adhesion enhancement liquid: first add diisostearyl malate to a magnetic stirrer, and then add 20% of the total amount of diisostearyl malate to it C30-45 alkyl Polymethylsiloxane, then start the agitator, adjust the temperature to 60°C, and the reaction speed is 350r / min, then add the porous phyllosilicate of 8% of the total amount of diisostearyl malate, di γ-aminopropyltriethoxysilane with 4-8% of the total amount of isostearyl malate, keep stirring for 1 hour, and finally add 40-50% of the total amount of diisostearyl malate Calcium carbonate, then apply a pressure of 10Mpa, and cont...

Embodiment 2

[0041] A kind of preparation method of polypropylene type hairbrush filament of the present embodiment, comprises the following steps:

[0042] Step 1, preparation of polypropylene matrix material: soak polypropylene in activated elasticizing solution for 2 hours at a temperature of 75°C, then dry at room temperature, and then perform silane activation treatment;

[0043] Step 2, preparation of adhesion enhancement liquid: first add diisostearyl malate to a magnetic stirrer, and then add 30% of the total amount of diisostearyl malate to it C30-45 alkyl Polymethylsiloxane, then start the agitator, adjust the temperature to 80°C, and the reaction speed is 380r / min, then add diisostearyl malate total 8-14% porous phyllosilicate, The gamma-aminopropyltriethoxysilane of 8% of diisostearyl malate total amount, keep the rotating speed and stir for 2h, finally add the nanometer calcium carbonate of 50% of diisostearyl malate total amount, Then apply a pressure of 20Mpa and continue t...

Embodiment 3

[0054] A kind of preparation method of polypropylene type hairbrush filament of the present embodiment, comprises the following steps:

[0055] Step 1, preparation of polypropylene matrix material: soak polypropylene in activated elasticizing solution for 1.5 hours at a temperature of 70°C, then dry at room temperature, and then perform silane activation treatment;

[0056] Step 2, preparation of adhesion enhancing liquid: first add diisostearyl malate to a magnetic stirrer, and then add 25% of the total amount of diisostearyl malate to the C30-45 alkyl Polymethylsiloxane, then start the stirrer, adjust the temperature to 70 ° C, the reaction speed is 365r / min, then add the porous layer silicate with 11% of the total amount of diisostearyl malate, di Gamma-aminopropyltriethoxysilane with 6% of the total amount of isostearyl malate, keep stirring for 1.5 hours at a rotating speed, and finally add nanocarbonic acid with 40-50% of the total amount of diisostearyl malate Calcium,...

PUM

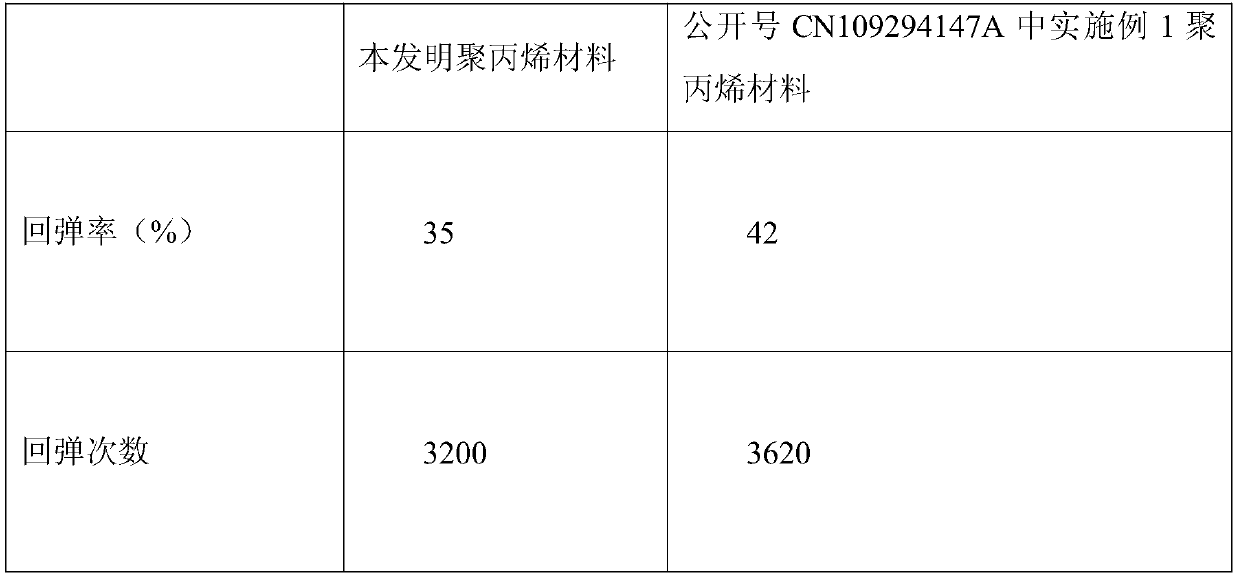

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com