Preparation method and application of a copper selenide nanosheet array for sodium-ion batteries with adjustable layer spacing

A technology of sodium ion battery and nanosheet array is applied in the field of preparation of copper selenide nanosheet array for sodium ion battery, which can solve the problems of unsuitability for large-scale production, high production cost, high energy consumption equipment and the like, and achieves easy industrialization The effect of mass production, low cost and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

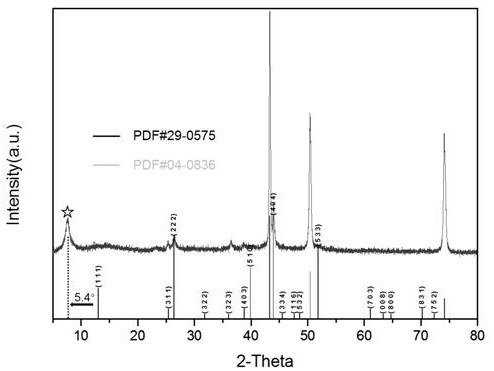

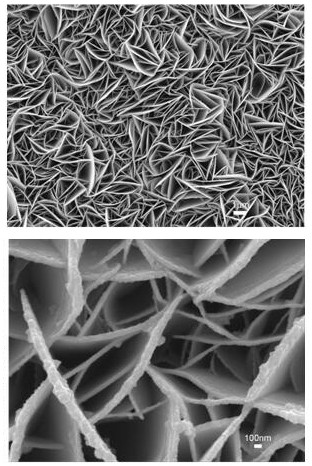

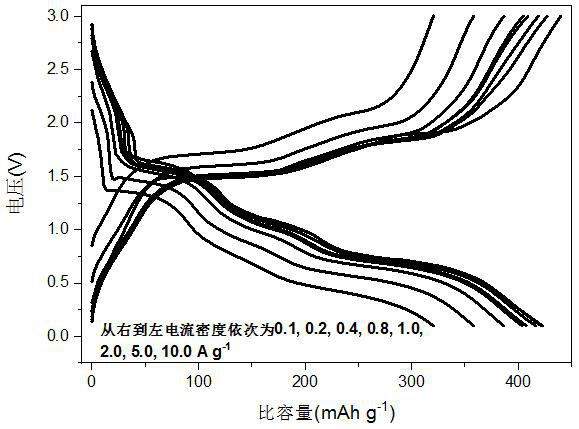

[0034] The preparation method of a copper selenide nanosheet array for a sodium ion battery with adjustable layer spacing in this embodiment is as follows:

[0035] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0036] (2) Dissolve 4 g sodium hydroxide in 100 ml, 0.001 mol L -1 0.110 g (0.001 mol) of selenium dioxide and 0.189 g (0.005 mol) of sodium borohydride were added in sequence, and stirred rapidly at 20°C for 10 min to completely dissolve the raw materials to obtain solution A.

[0037] (3) Put the copper foil treated in step (1) in solution A, react at 20 °C for 4 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array fo...

Embodiment 2

[0045] The preparation method of a copper selenide nano-array for a sodium-ion battery with adjustable layer spacing in this embodiment is as follows:

[0046] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0047] (2) Dissolve 8 g sodium hydroxide in 100 ml, 0.005 mol L -1 0.346 g (0.002 mol) of sodium selenite and 0.378 g (0.01 mol) of sodium borohydride were added in sequence, and stirred rapidly at 30°C for 30 minutes to completely dissolve the raw materials to obtain solution A.

[0048] (3) Put the copper foil treated in step (1) in solution A, react at 30 °C for 4 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array for s...

Embodiment 3

[0051] The preparation method of a copper selenide nano-array for a sodium-ion battery with adjustable layer spacing in this embodiment is as follows:

[0052] (1) Cut the high-purity copper foil into a size of 1 cm×1 cm, and pass through acetone, 1 mol L -1 Hydrochloric acid solution and deionized water were ultrasonically washed to remove organic matter and oxides on the copper foil surface, and then dried in vacuum at 60 °C for 5 h.

[0053] (2) Dissolve 10 g sodium hydroxide in 100 ml, 0.01 mol L -1 0.237 g (0.003 mol) of selenium powder and 0.81 g (0.015 mol) of potassium borohydride were added in sequence, and stirred rapidly at 40 °C for 60 min to completely dissolve the raw materials to obtain solution A.

[0054] (3) Put the copper foil treated in step (1) in solution A, react at 40 °C for 3 h, take out the copper foil, wash it with deionized water and ethanol several times, and then dry it in vacuum at 60 °C for 10 h That is, a copper selenide nanosheet array for s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com