A kind of iron ion imprinting polymer and its preparation method and application

A technology of imprinting polymers and iron ions, which is applied in the field of separation, can solve the problems of complex preparation process, inapplicability to large-scale industrial production, and low adsorption capacity, and achieve the effect of easy preparation of raw materials, good application prospects, and simple reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

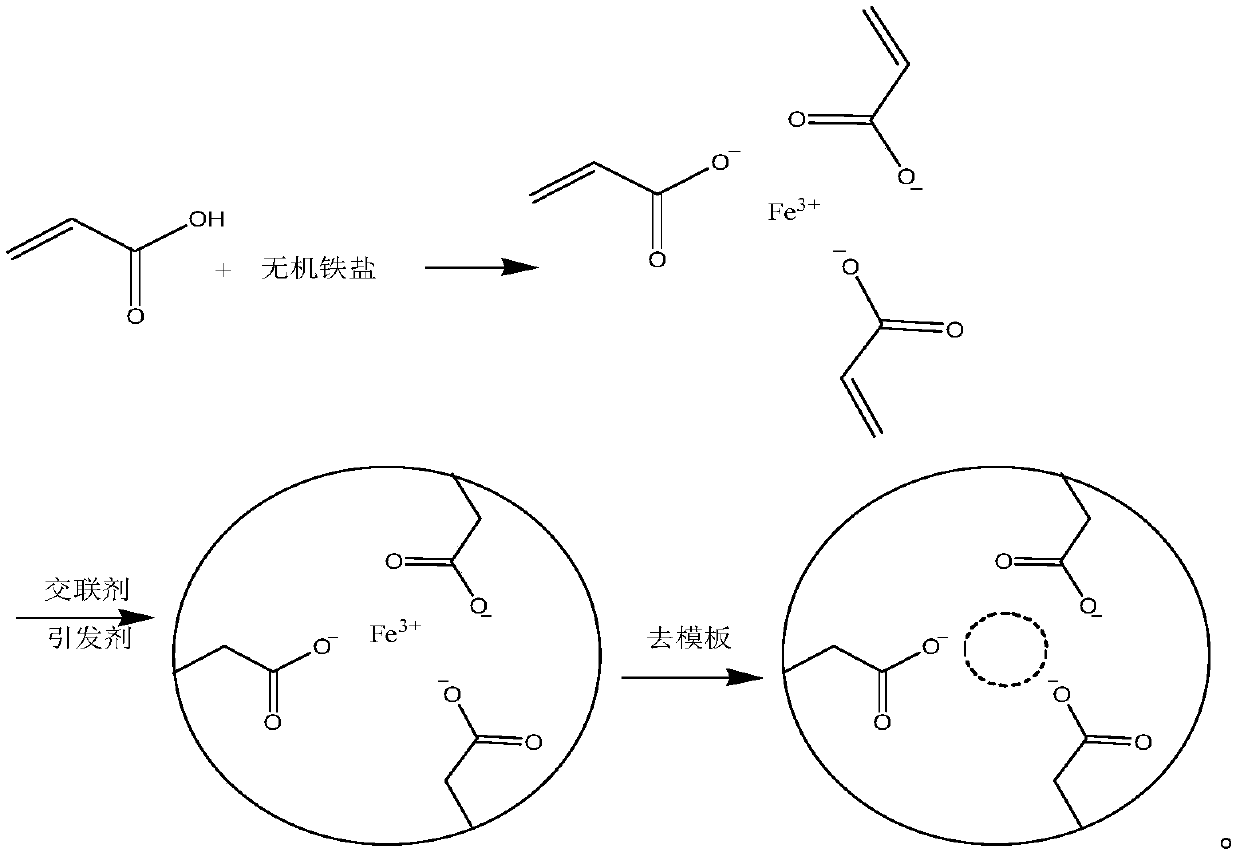

[0063] This example provides a method for preparing the iron ion imprinted polymer provided in this application, the specific method is:

[0064] (1) Dissolve 1mmol ferric nitrate nonahydrate and 9mmol acrylic acid 9:1 in 10mL solvent, add 3.85mL (20mmol) ethylene glycol dimethacrylate and 0.05g initiator after stirring for 2h, and pass nitrogen gas after stirring for 10min , seal the container and place it in a constant temperature oven at 60°C for 24 hours of reaction.

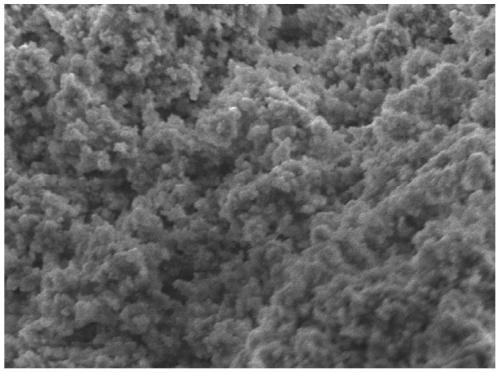

[0065] (2) Take out the solid polymer obtained after the reaction, grind and sieve it to 40-80 mesh, wash the obtained powder with ethanol and deionized water successively to remove unreacted substances, and separate the solid and liquid after washing The polymer is leached with 6mol / L HCl to remove inorganic iron salts.

[0066] (3) The polymer obtained after leaching was washed with deionized water until the pH value of the washing water was nearly neutral, and then the washed polymer was dried in an oven...

Embodiment 2

[0081] (1) Dissolve 1mmol ferric nitrate nonahydrate and 3mmol acrylic acid 3:1 in 10mL solvent, stir for 2h, add 3.85mL ethylene glycol dimethacrylate and 0.05g initiator, stir for 10min and then pass nitrogen gas into the container After sealing, put it into a constant temperature oven at 60°C and react for 24 hours.

[0082](2) Take out the solid polymer obtained after the reaction, grind and sieve it to 40-80 mesh, wash the obtained powder with ethanol and deionized water successively to remove unreacted substances, and separate the solid and liquid after washing The polymer is leached with 6mol / L HCl to remove inorganic iron salts.

[0083] (3) The polymer obtained after leaching was washed with deionized water until the pH value of the washing water was nearly neutral, and then the washed polymer was dried in an oven at 60° C. to obtain the iron ion imprinted polymer.

[0084] (4) In order to obtain the relative selectivity coefficient of the prepared iron ion-imprinted...

Embodiment 3

[0087] (1) Dissolve 1mmol ferric nitrate nonahydrate and 6mmol acrylic acid 6:1 in 10mL solvent, stir for 2h, add 3.85mL ethylene glycol dimethacrylate and 0.05g initiator, stir for 10min and then pass nitrogen gas into the container After sealing, put it into a constant temperature oven at 60°C and react for 24 hours.

[0088] (2) Take out the solid polymer obtained after the reaction, grind and sieve it to 40-80 mesh, wash the obtained powder with ethanol and deionized water successively to remove unreacted substances, and separate the solid and liquid after washing The polymer is leached with 6mol / L HCl to remove inorganic iron salts.

[0089] (3) The polymer obtained after leaching was washed with deionized water until the pH value of the washing water was nearly neutral, and then the washed polymer was dried in an oven at 60° C. to obtain the iron ion imprinted polymer.

[0090] (4) In order to obtain the relative selectivity coefficient of the prepared iron ion-imprinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com