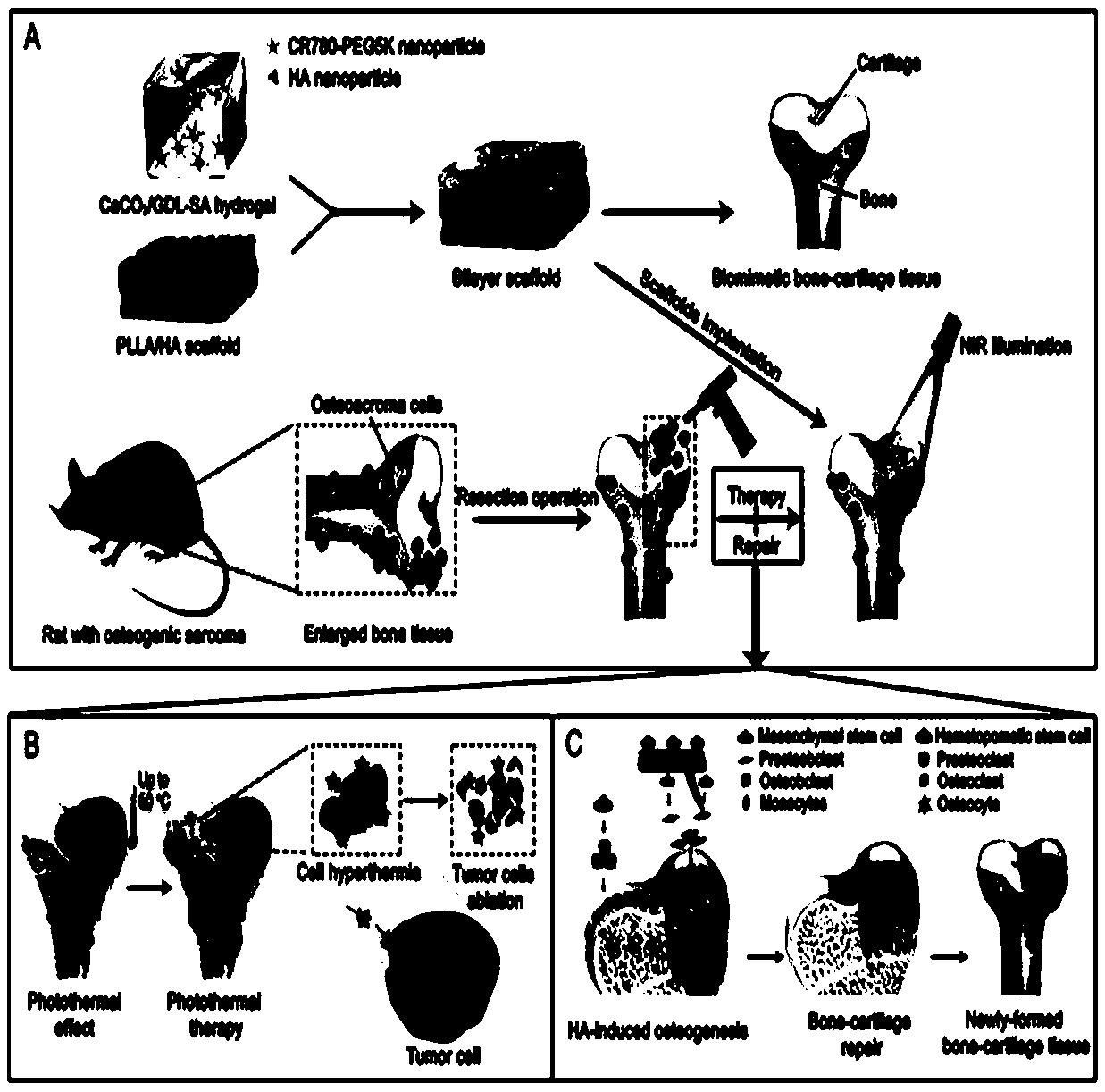

Difunctional integrated bone-cartilage composite tissue engineering scaffold for clinic treatment of osteosarcoma

A clinical treatment and composite tissue technology, applied in tissue regeneration, prosthesis, anti-tumor drugs, etc., to achieve the effect of promoting simultaneous regeneration, good photothermal effect, and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

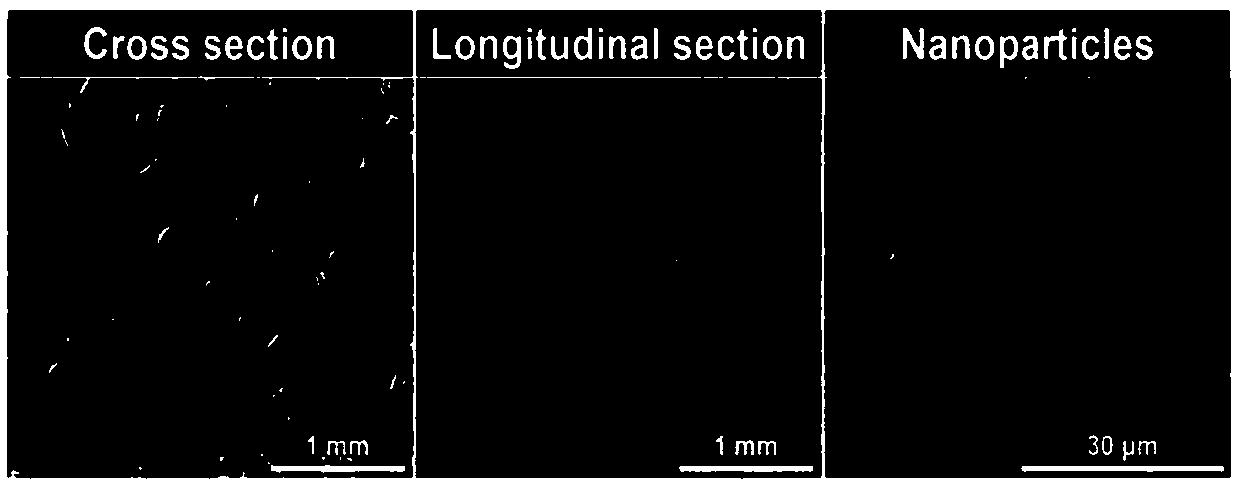

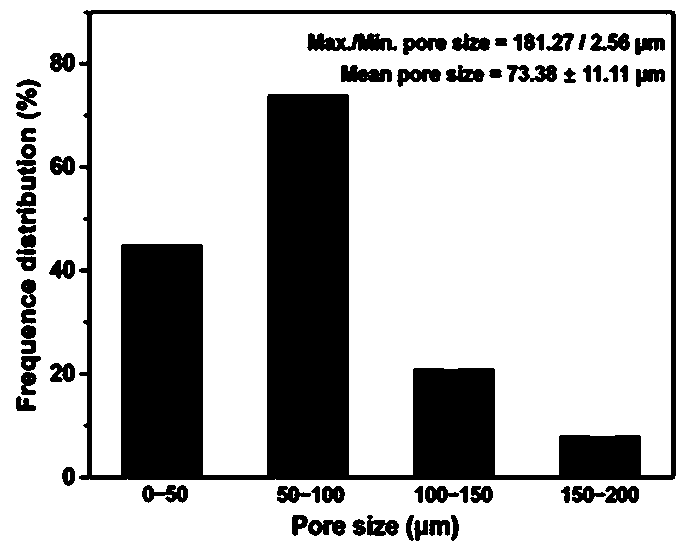

[0052] (1) Prepare a certain concentration of PLLA / chloroform solution (8%, W / V ), then weigh a certain amount of HA (the mass fraction of HA in PLLA / chloroform solution is 15%, W / V )) dispersed in PLLA / chloroform solution, and ensure the uniform distribution of HA in the polymer matrix to obtain PLLA / HA solution;

[0053] (2) In order to prepare a hard bone scaffold with a certain pore size, NaCl particles with a weight ratio of NaCl to PLLA / HA solution of 6:1 were sieved (180-90 mesh), and then slowly poured into the PLLA / HA solution, using Stir quickly with a glass rod until uniform, then pour into homemade glass molds;

[0054] (3) Put the mold in a fume hood to exhaust for 12 h, then put it in a vacuum oven set at 60 °C to dry for 24 h, and finally soak the formed hard bone scaffold in deionized water for 7 days to complete particle leaching Hole making;

[0055] (4) In order to improve the interfacial compatibility of the composite scaffold, a certain mass of NaOH par...

Embodiment 2

[0071] (1) Prepare a certain concentration of PLLA / chloroform solution (12%, W / V ), then weighed a certain mass of HA (the mass fraction of HA in PLLA / chloroform solution was 25%, W / V ) is dispersed in PLLA / chloroform solution, and ensures the uniform distribution of HA in the polymer matrix to obtain PLLA / HA solution;

[0072] (2) In order to prepare a hard bone scaffold with a certain pore size, NaCl particles with a weight ratio of NaCl to PLLA / HA solution of 6:1 were sieved (180-90 mesh), and then slowly poured into the PLLA / HA solution, using Stir quickly with a glass rod until uniform, then pour into homemade glass molds;

[0073] (3) Put the mold in a fume hood to exhaust for 18 h, then dry it in a vacuum oven at 65 °C for 30 h, and finally soak the formed hard bone scaffold in deionized water for 10 days to complete particle leaching Hole making;

[0074] (4) In order to improve the interfacial compatibility of the composite scaffold, a certain mass of NaOH particle...

Embodiment 3

[0080] (1) Prepare a certain concentration of PLLA / chloroform solution (8%, W / V ), then weigh a certain amount of HA (the mass fraction of HA in PLLA / chloroform solution is 15%, W / V ) is dispersed in PLLA / chloroform solution, and ensures the uniform distribution of HA in the polymer matrix to obtain PLLA / HA solution;

[0081] (2) In order to prepare a hard bone scaffold with a certain pore size, NaCl particles with a weight ratio of NaCl to PLLA / HA solution of 7:1 were sieved (180-90 mesh), and then slowly poured into the PLLA / HA solution, Stir quickly with a glass rod until uniform, then pour into homemade glass molds;

[0082] (3) Put the mold in a fume hood to exhaust for 12 h, then put it in a vacuum oven set at 55 °C to dry for 12 h, and finally soak the formed hard bone scaffold in deionized water for 7 days to complete particle leaching Hole making;

[0083] (4) In order to improve the interfacial compatibility of the composite scaffold, a certain mass of NaOH partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com