Oxide passivation contact solar cell and preparation method thereof

A solar cell and oxide technology, applied in the field of solar cells, can solve the problems of poor passivation effect and enhanced passivation effect, and achieve the effects of enhanced passivation effect, low cost, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

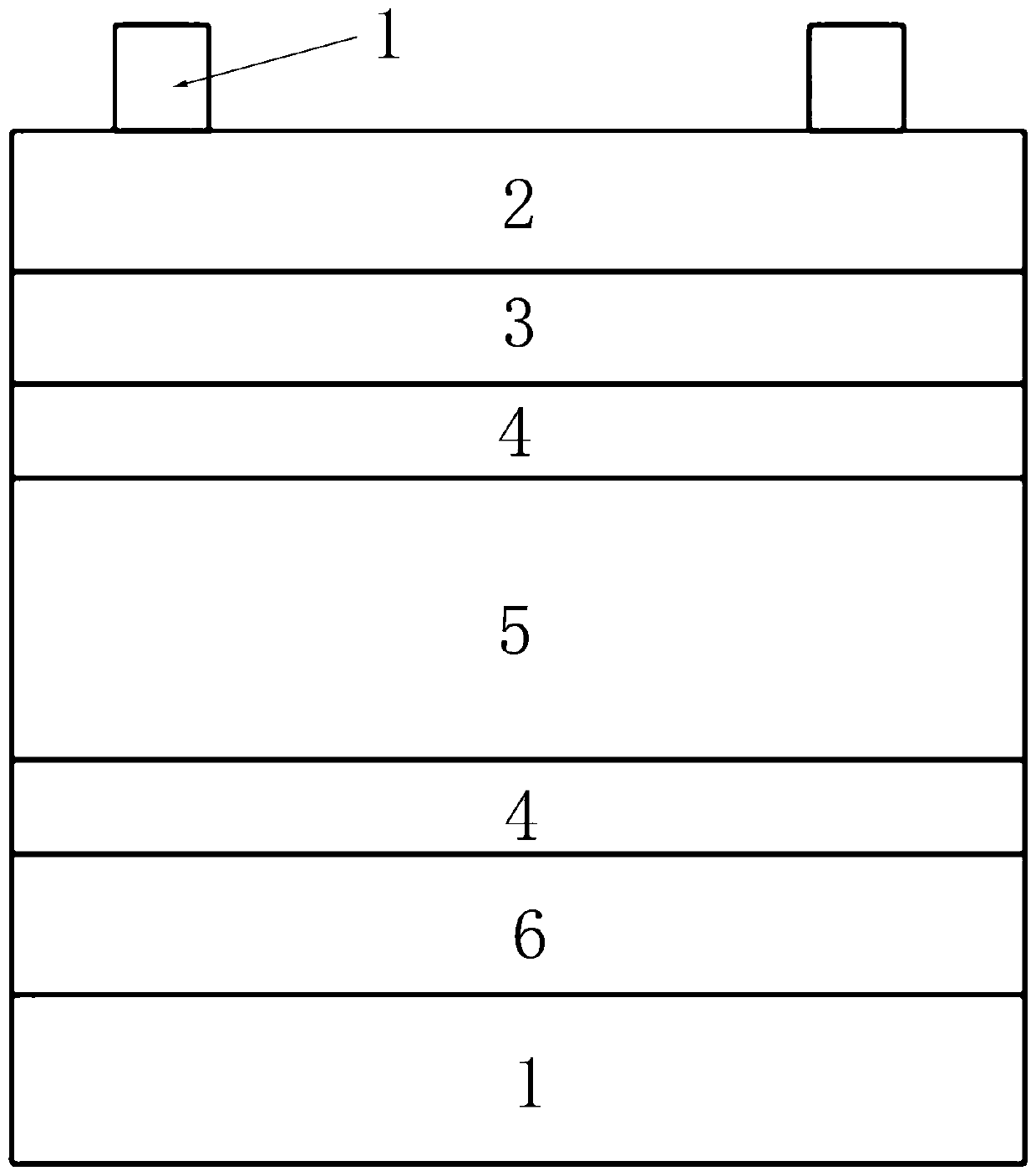

[0028] See attached picture. The battery described in this embodiment has the following structure from top to bottom: Ag electrode 1, ITO thin film 2 (70nm), NiOx:Mg thin film 3 (10nm), SiOx layer 4 (1.4nm), n-c-Si layer 5 , SiOx layer 4 (1.4nm), TiOx thin film 6 (10nm), Ag electrode 1.

[0029] When preparing:

[0030] 1. Wafer cleaning

[0031] The oxide-passivated non-doped crystalline silicon solar cell designed in this embodiment, in order to reduce the impurity concentration on the surface of the silicon wafer and reduce the interface defect state density between the surface of the silicon wafer and the passivation layer, therefore clean the surface of the silicon wafer The requirements are very high, and the cleaning of the silicon wafer is also critical to the subsequent growth of ultra-thin silicon oxide.

[0032] The silicon wafer used in the experiment is an n-type double-sided polished Czochralski single crystal silicon wafer with a thickness of 180-220 μm and a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com