Drawing process method for imitated bristle brush

A process method and wire drawing technology, which are applied in the manufacture of brushes, bristles, and rayon, can solve the problems of affecting the use effect and service life, the inability to use plastic brushes, and the easy damage of the brushed surface, so as to achieve low cost and low cost , the effect of high straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

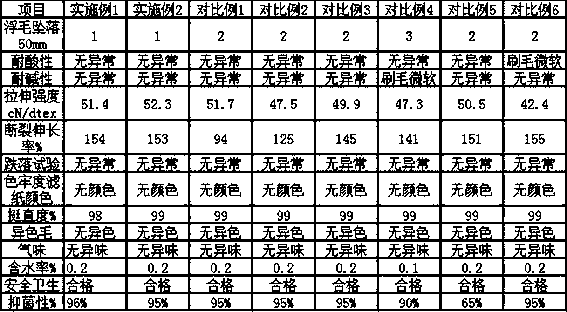

Examples

Embodiment 1

[0020] A method for imitating bristle brush drawing, comprising the following steps: (1) Weighing raw materials: including the following components in parts by weight: 141 parts of vinyl acetate resin, 2 parts of anti-aging agent, 1.5 parts of heat stabilizer, dispersant 67.5 parts, 11 parts of brominated octyl phenolic resin, 43.2 parts of thermoplastic polyurethane elastomer;

[0021] (2) Rapid drying: The raw materials are fed into the high-speed mixer through the feeder and continuously rotated and stirred, heated to 100°C for 20 minutes, and the uniformly dispersed materials are sent to the internal mixer for 4 minutes to obtain spinning melt body;

[0022] (3) Heat 200 parts of a mixed solution containing 12.5% potassium hydroxide, 10.5% thiourea aqueous solution, 4.2% propyl gallate, and water to 50°C, and then weigh the fluorinated graphene Add 1.3 parts of oxide, 1.5 parts of methyl chitosan, 1.7 parts of hydroxy polyglucosamine, 4 parts of xanthan ester gum, 15 pa...

Embodiment 2

[0031] A method for imitating bristle brush drawing, comprising the following steps: (1) Weighing raw materials: including the following components in parts by weight: 126 parts of vinyl acetate resin, 1 part of anti-aging agent, 1.5 parts of heat stabilizer, dispersant 61 parts, 11 parts of brominated octyl phenolic resin, 31.5 parts of thermoplastic polyurethane elastomer;

[0032] (2) Rapid drying: The raw materials are fed into the high-speed mixer through the feeder and continuously rotated and stirred, heated to 70°C for 10 minutes, and the uniformly dispersed materials are sent to the internal mixer for 4 minutes to obtain spinning melt body;

[0033] (3) Heat 200 parts of a mixed solution containing 9.5% potassium hydroxide, 10.5% thiourea aqueous solution, 2.3% propyl gallate, and water to 40°C, and then weigh the fluorinated graphene 1.3 parts of oxides, 1.5 parts of methyl chitosan, 0.6 parts of hydroxypolyglucosamine, 2 parts of xanthan ester gum, 15 parts of aqua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com